Method and device of electromagnetism movement stacking

A mobile device, electromagnetic force technology, applied in the stack receiving device, transportation and packaging, sending objects, etc., can solve the problem of poor movement stability of the wide-width platen, scratches of the wide-width platen, and uneven stacking, etc. problems, to avoid hydraulic oil leakage pollution, good self-locking, strong tensile and compressive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

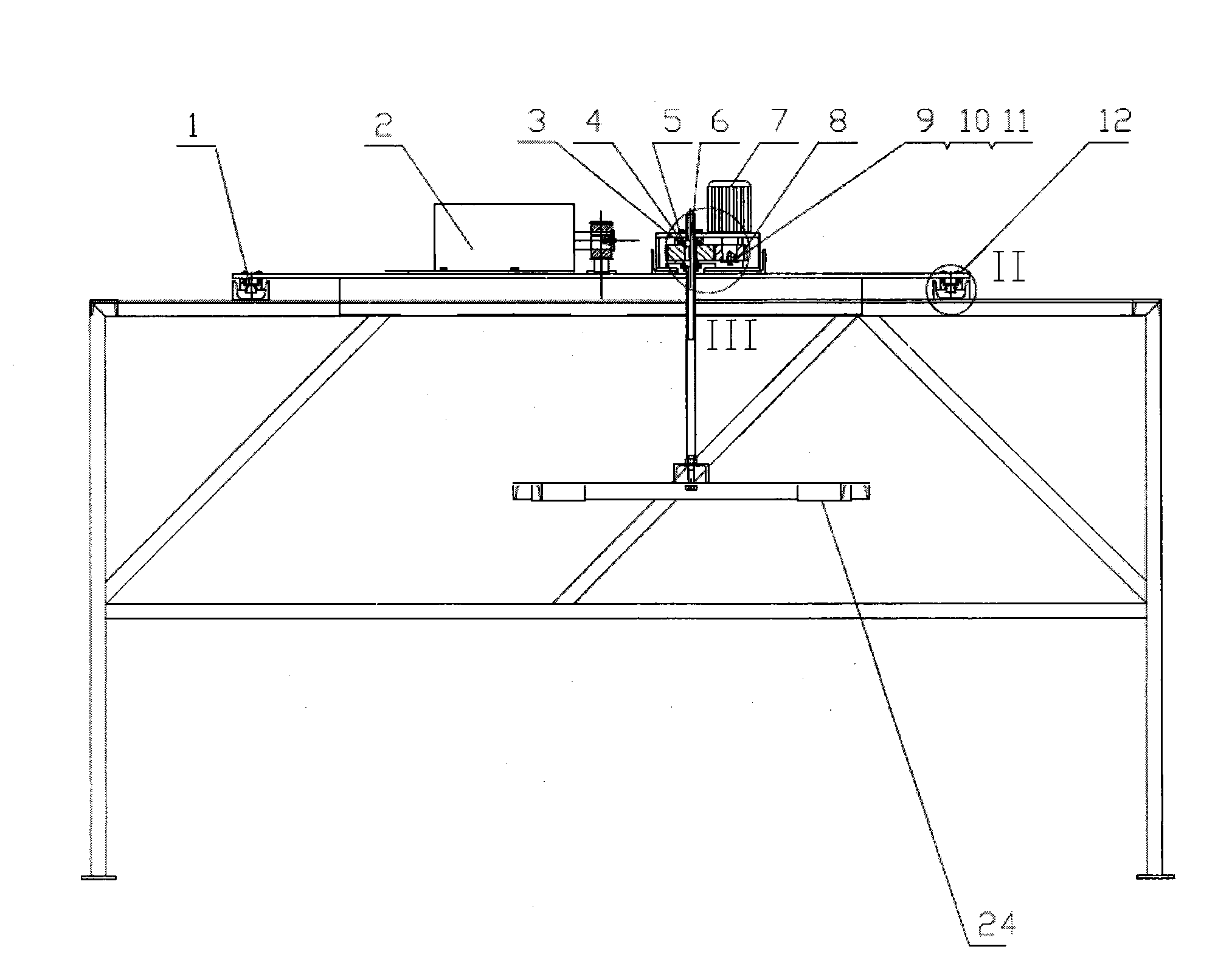

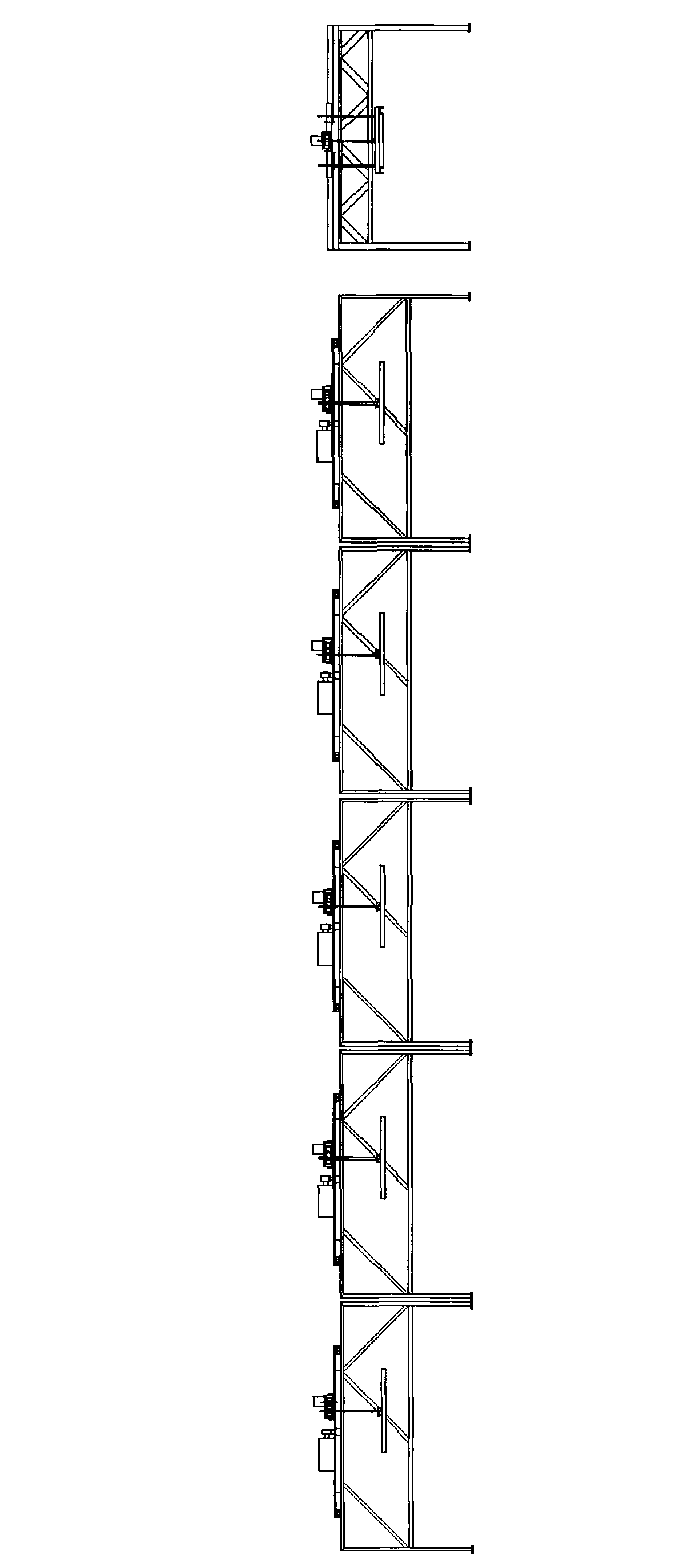

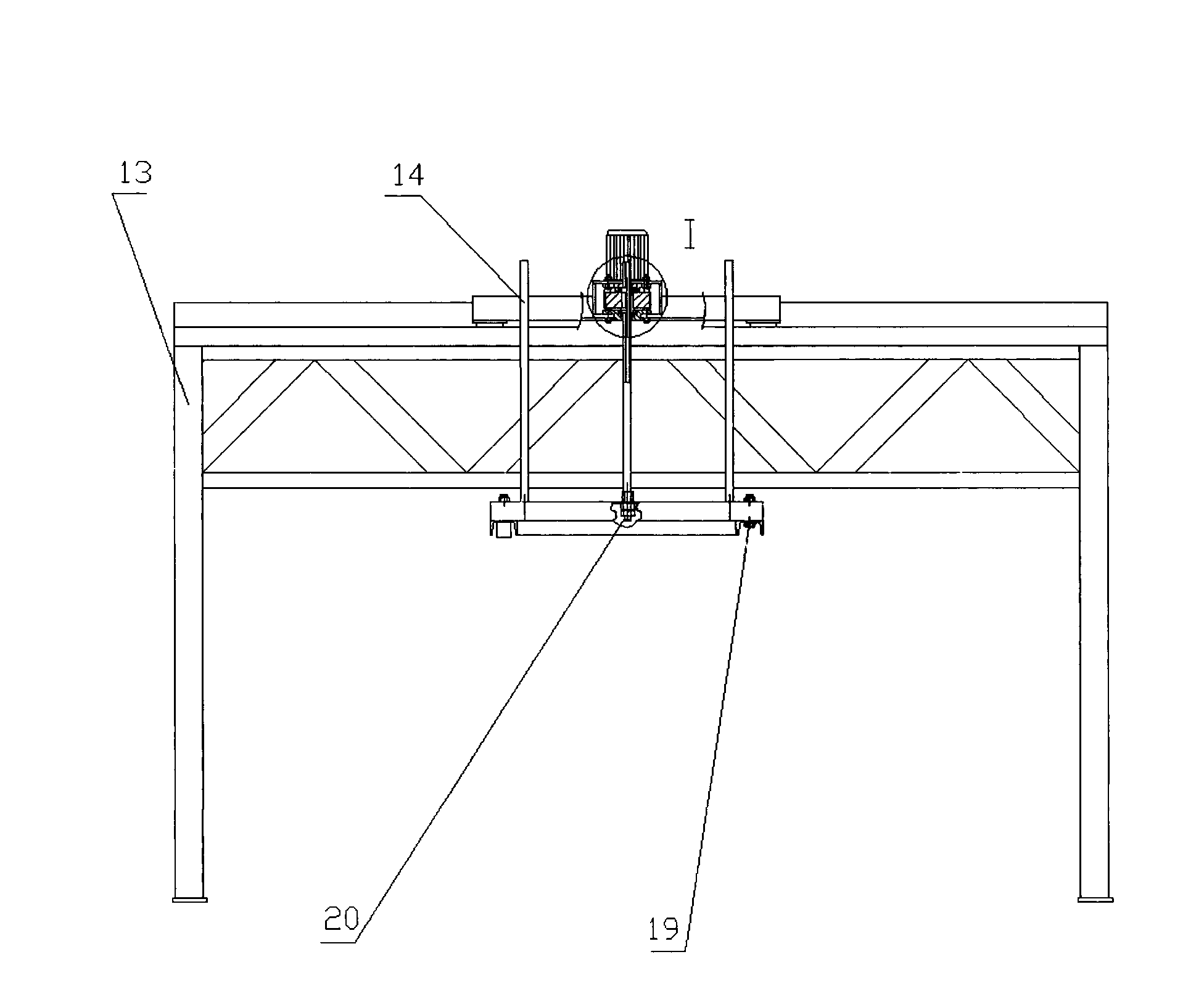

[0028] The parameters of the wide-width profiled plate captured by the electromagnetic mobile stacking device are: plate width 992mm, plate length 10000mm, plate thickness 0.48mm, production line profile production speed v=1m / s, and thus each working cycle of the picking device for 10s. The design profile is absorbed and lifted away from the conveying line at a height of 50mm, that is, the displacement of the pick-up device is 50mm, and the speed of the screw lifting and moving is 0.1m / s, that is, the nut speed is about 1500-2000r / min; from the conveying line to the stacking platform The distance passed is 1200mm, and the maximum speed of translation is about 0.7m / s, and the device needs to realize each action in one cycle and the required time is: the pick-up device is lowered to the conveying line, the suction electromagnet is energized to absorb the profile, and it takes time 1.5s; the pick-up device rises to a certain height, and it takes 1s; the pick-up device grabs the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com