Feeding device of flexible printed circuit (FPC) board and keyboard base plate automated assembly system

An automatic assembly, PCB board technology, applied in the direction of electrical components, electrical switches, circuits, etc., can solve the problems of low production efficiency, easy deformation, large volume, etc., to achieve the effect of improving production efficiency, reducing quantity, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

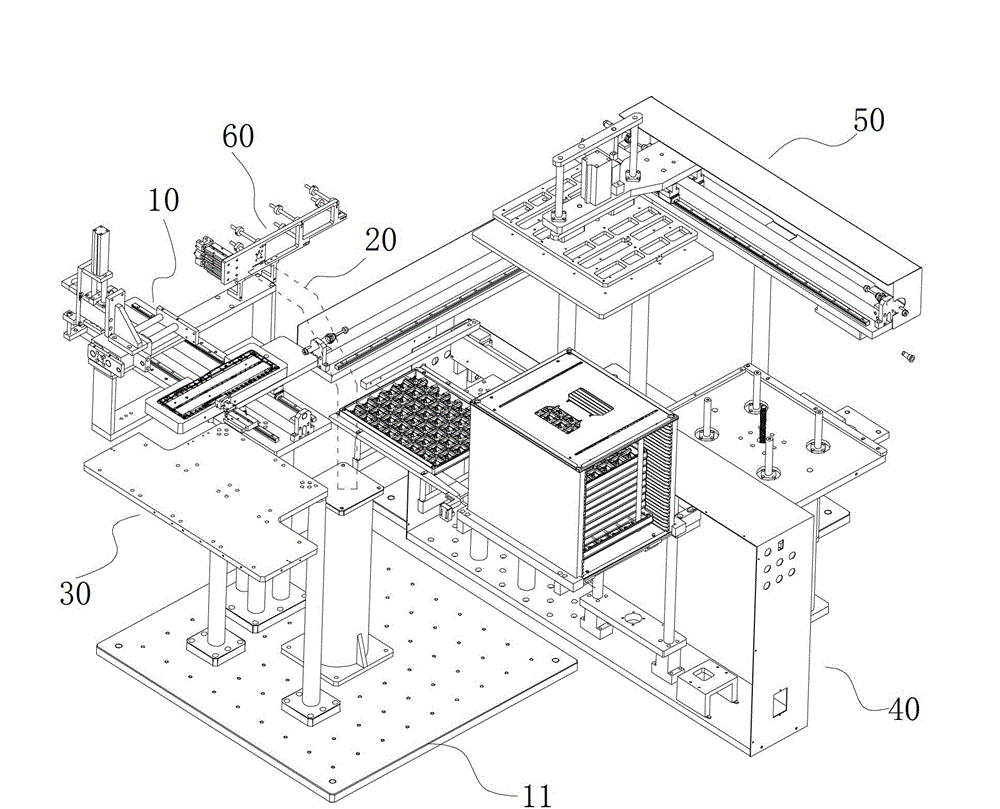

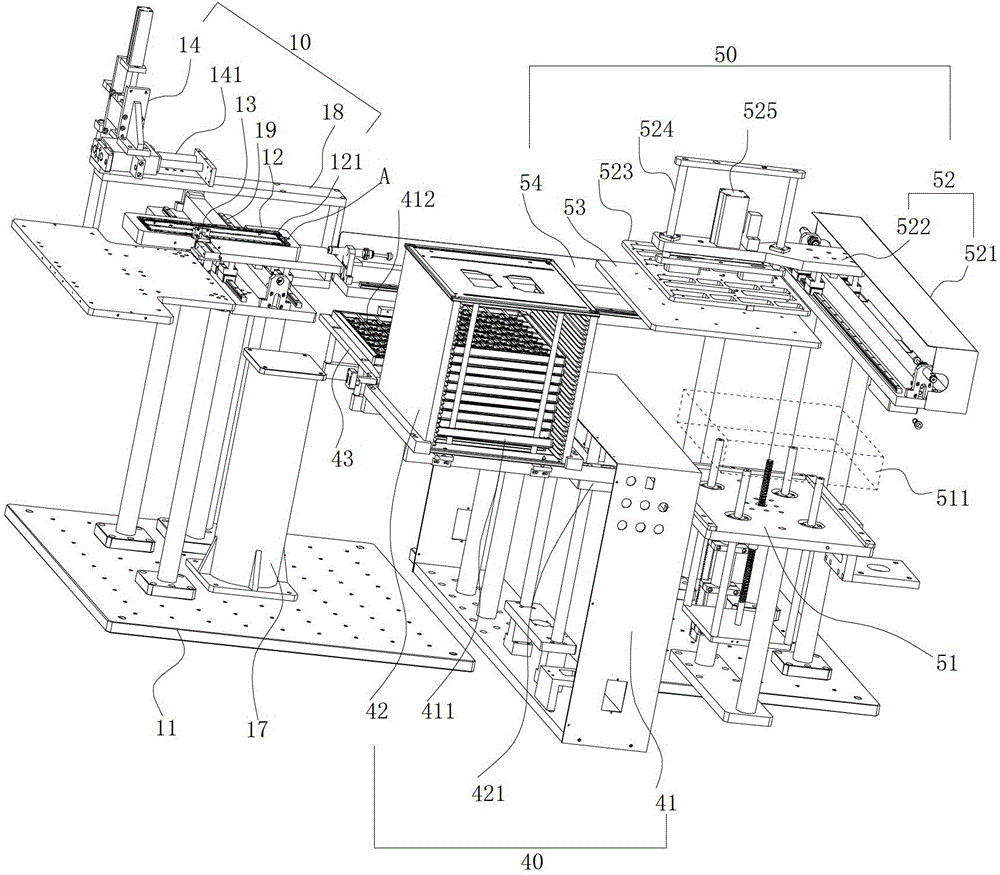

[0048] Such as Figure 1 to Figure 5 As shown, the keyboard bottom plate automatic assembly system of the present invention includes a keyboard bottom plate assembly platform 10, and also includes: a robot 20 arranged on the base 11; a material table 30 arranged on the side of the robot 20, and the material table 30 includes an iron bar feeding area 31 and the silicone strip feeding area 32; and the PCB board feeding device 40 and the FPC board feeding device 50 located on the other side of the robot 20; the movable end of the robot 20 is provided with a multi-purpose clamping mechanism 60. The robot grabs the keyboard bottom plate, PFC board, PCB board, silicone strip and iron strip one by one and places them in the set position, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com