Fast ignition target fuel layering device based on fluid magnetic suspension and fast ignition target fuel layering method based on fluid magnetic suspension

A fuel stratification and magnetic levitation technology, applied in the field of inertial confinement nuclear fusion, can solve the problems of limited use range, low fuel filling amount, and ineffectiveness, and achieve the effect of expanding the use range, convenient operation and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

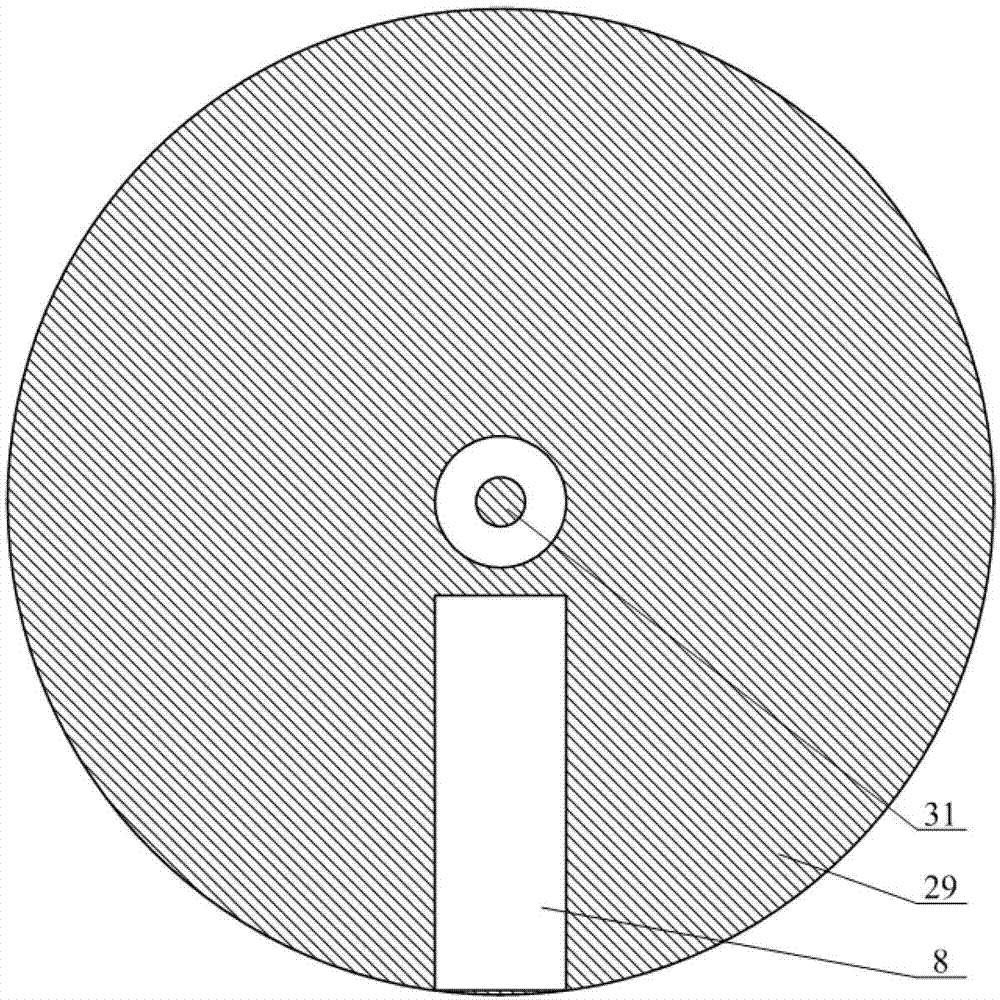

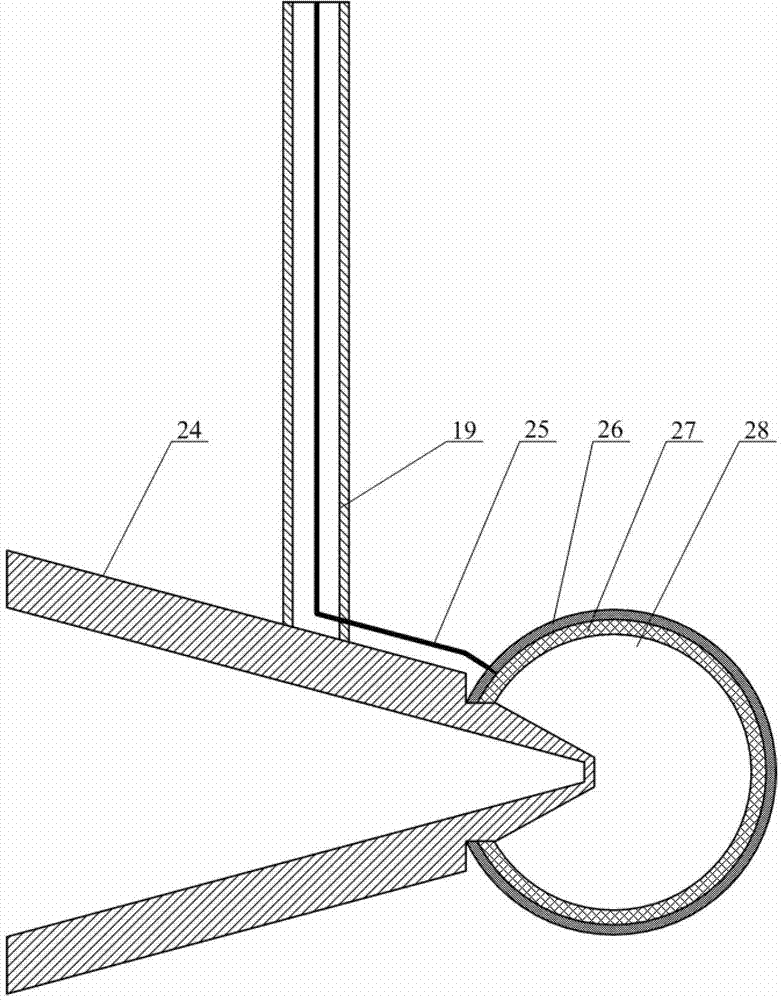

[0028] refer to figure 1, a fast ignition target fuel stratification device based on fluid magnetic levitation, including a turntable mechanism 1, the turntable mechanism 1 is composed of a drive shaft 31, a turntable 29 and a target chamber 8, the drive shaft 31 is parallel to the ground, and the turntable 29 is fixed on the drive shaft 31, the disk surface of the rotating disk 29 is perpendicular to the central axis of the drive shaft 31, and the driving shaft 31 can be used to rotate the rotating disk 29 counterclockwise in the vertical plane. The disk surface of the rotating disk 29 is grooved radially, and the target chamber 8 is installed. Target making room 8 profile is cube, and its cross section is square, and the symmetry axis of its longitudinal section is along the radial direction of rotating disk 29; When the target chamber 8 is in the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com