Underwater silt remover, underwater silt removing device comprising the same and operation method thereof

A technology of underwater dredging machine and submersible motor, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problem of high production cost and complex structure of underwater dredging machine. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

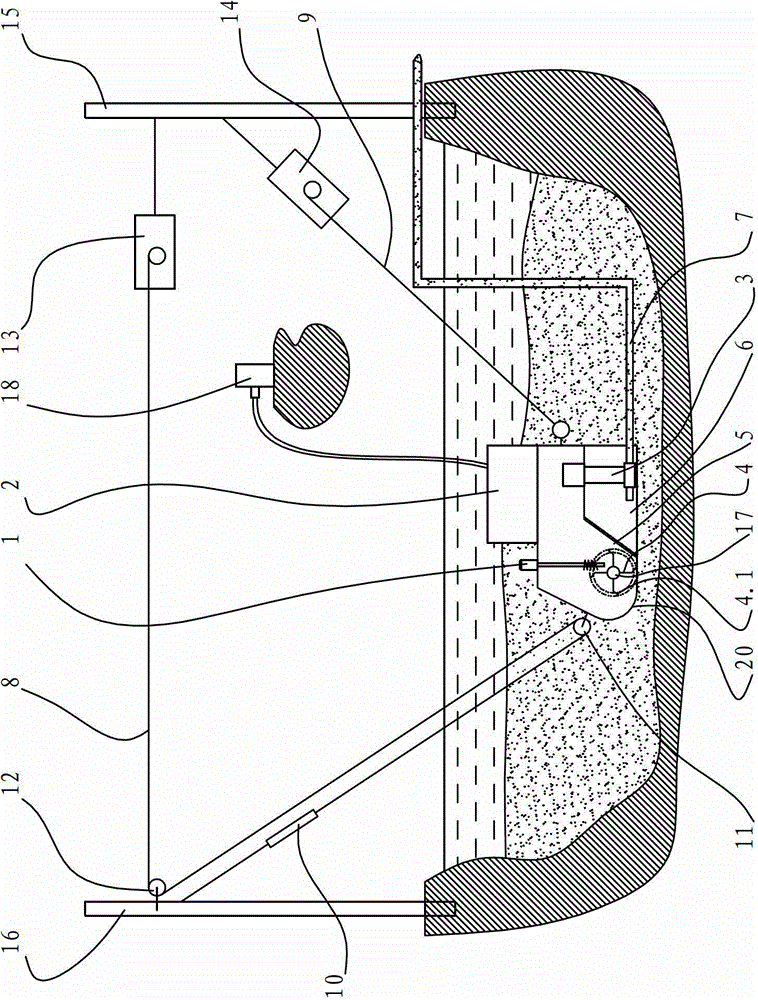

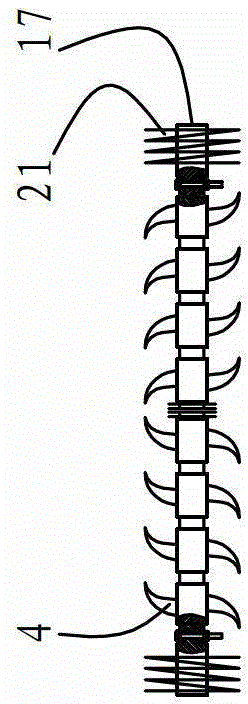

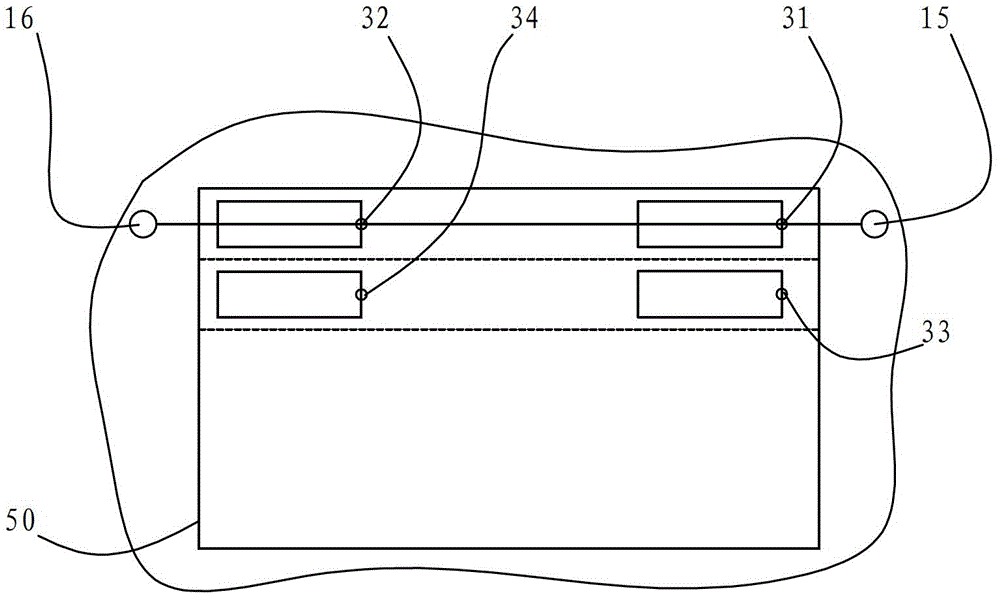

[0090] see Figure 1-Figure 2 , the underwater desilting machine, including the collecting bin 6 arranged in the frame 20, the inlet of the mud pump 3 communicates with the collecting bin 6, the outlet of the mud pump 3 communicates with the mud outlet pipe 7, and the frame 20 is also provided with Disturbance stirring mechanism, this disturbance stirring mechanism comprises the rotary tiller blade 4 with ridging function and the submersible motor 1 and the speed reducer for driving the rotary tiller blade 4 to rotate, and the filter screen 5 is arranged on the collecting bin 6, and the rotary tiller blade 4 is located at The front of the filter screen 5 and the collection bin 6.

[0091] The submersible motor 1 is suspended on the frame 20, and the submersible motor 1 is connected to the rotating shaft 17 arranged in the frame 20 through a reducer, and more than two rotary blades 4 are relatively symmetrically arranged on the rotating shaft 17; the rotating shaft 17 The two ...

no. 2 example

[0153] see Figure 5 , In the present embodiment, the submersible motor 1 is located at the oblique rear top of the rotary blade 4 . At this time, the submersible motor 1 is arranged horizontally, and the sealing level requirement of the submersible motor 1 is slightly higher than that of the first embodiment.

[0154] Refer to the first embodiment for the rest of the undescribed parts, and will not repeat them here.

no. 3 example

[0156] see Figure 6 , In this embodiment, the submersible motor 1 is installed obliquely, and the submersible motor 1 is located at the oblique front and top of the rotary blade 4 . The front part or the front lower half of the frame 20 is pointed, which can reduce the resistance of advancement and prevent subsidence. Refer to the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com