Superplastic forming die for aluminum alloy coating parts for railway vehicles and forming method for superplastic forming die

A technology for superplastic forming and rail vehicles, applied in the field of superplastic forming molds and their forming, can solve the problems of low production efficiency and high production cost, and achieve the effects of simple structure, improved production efficiency and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

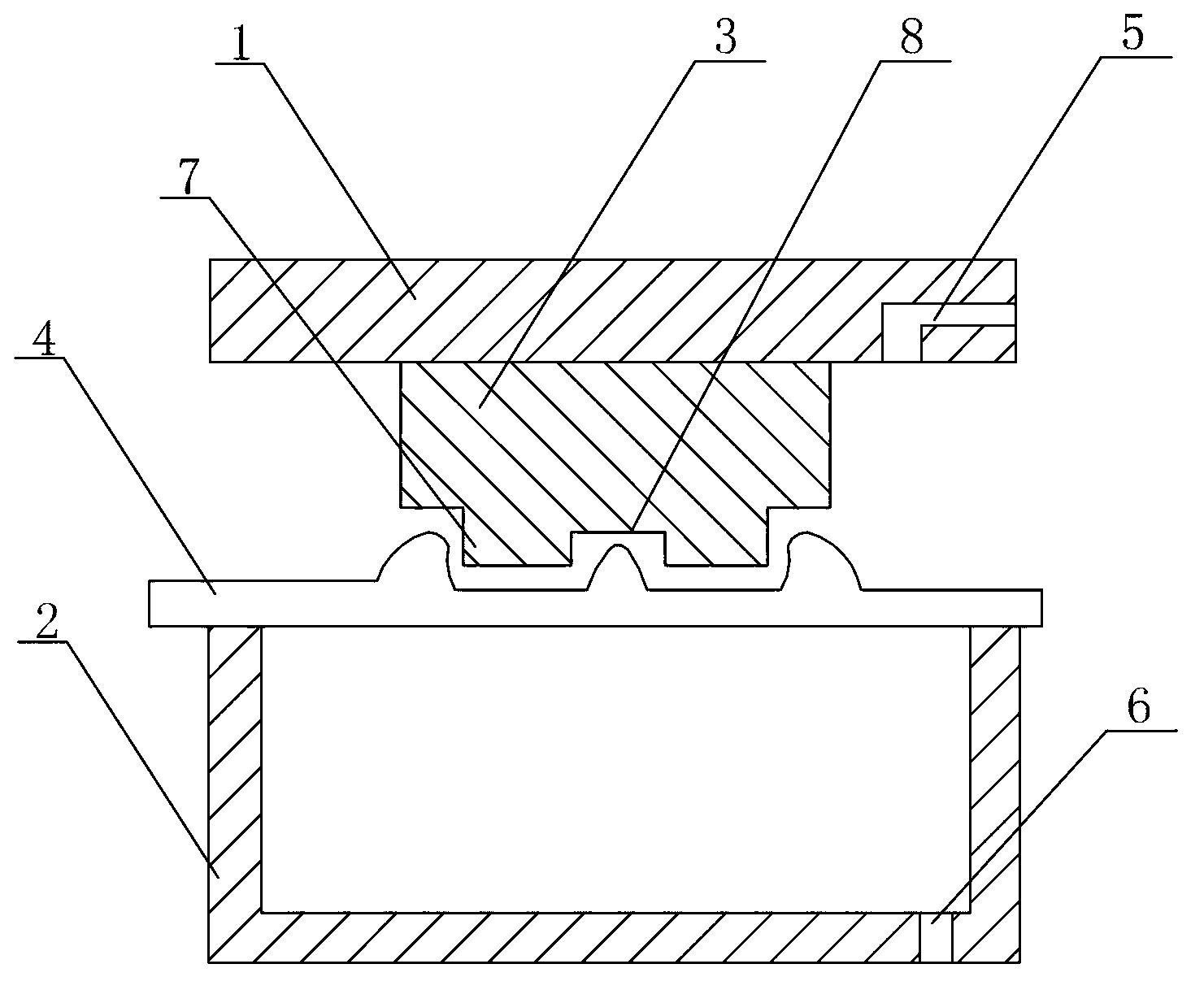

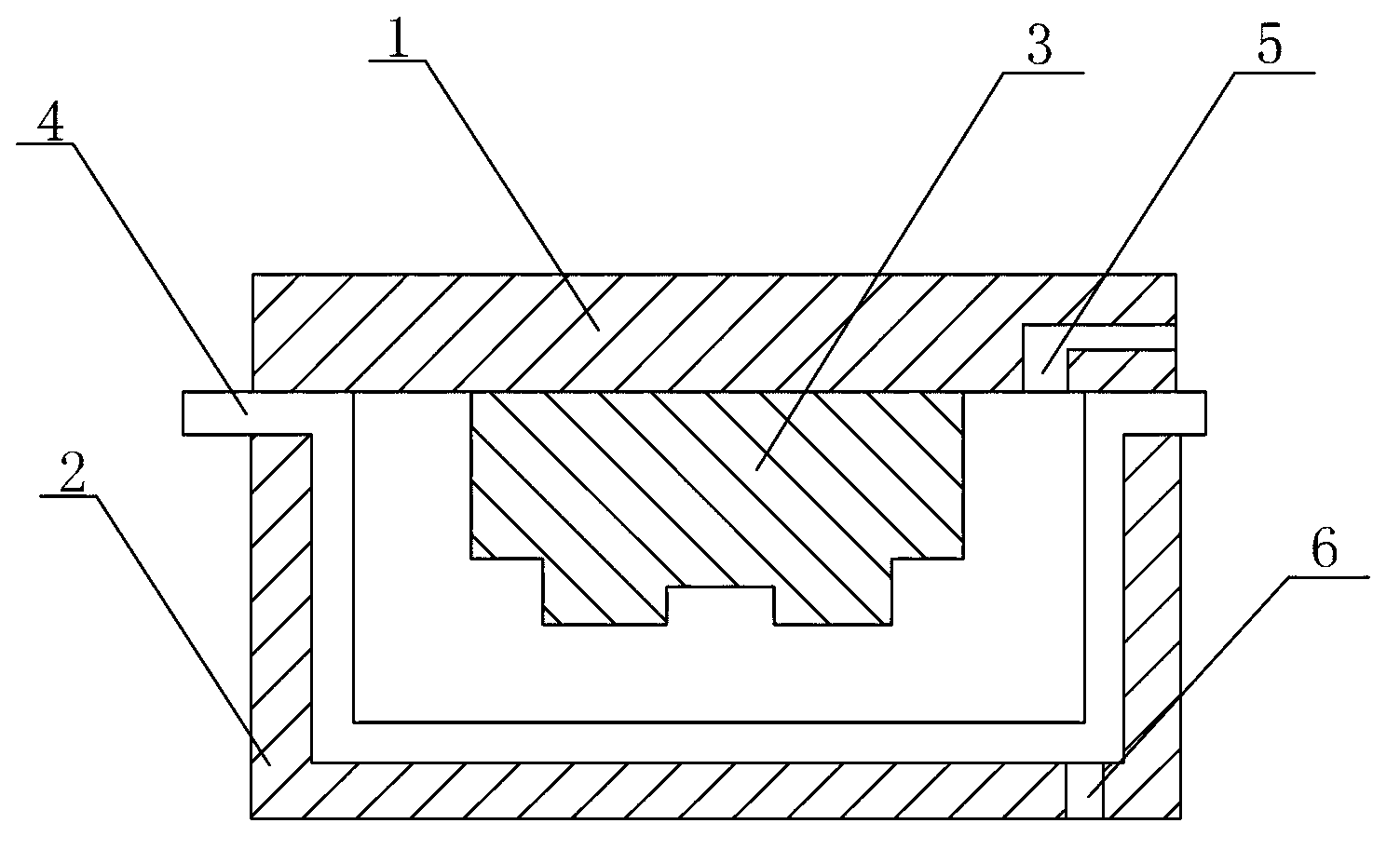

[0024] Specific implementation mode 1: Combination figure 1 with figure 2 To explain this embodiment, the superplastic forming mold for aluminum alloy covering parts for rail vehicles in this embodiment includes an upper template 1 and a concave mold 2. The upper template 1 is set directly above the concave mold 2, and the superplastic forming mold also includes The punch 3, the punch 3 is fixedly mounted on the lower end of the upper mold plate 1, an air-filled cavity is formed between the punch mold 3 and the female mold 2, the aluminum alloy sheet 4 is set on the upper end of the female mold 2, and the upper mold plate 1 is provided with air inlets 5. The lower end of the female mold 2 is provided with a vent 6; the lower end of the male mold 3 is provided with a boss 7; the shoulder of the boss 7 and the side wall of the male mold 3 are rounded, and the boss 7 A second reverse extrusion sealing groove 8 is provided in the middle of the.

[0025] Although the pre-bending for...

specific Embodiment approach 2

[0028] Specific implementation manner two: combination figure 1 with figure 2 To illustrate this embodiment, the length of the second reverse extrusion sealing groove 8 of this embodiment is 1 to 2 times the wall thickness of the aluminum alloy sheet. With this setting, the sealing effect is better. The other composition and connection relationship are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 1 with figure 2 To illustrate this embodiment, the fillet radius of the first fillet sealing groove 7 of this embodiment is 10 to 15 times the wall thickness of the aluminum alloy sheet. So set up. The other composition and connection relationship are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com