Electromagnetic relay with armature part convenient to insert

A technology of electromagnetic relays and armatures, which is applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of high difficulty, unfixed position of armature parts, and difficulties in automatic assembly, so as to reduce assembly difficulty and improve assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

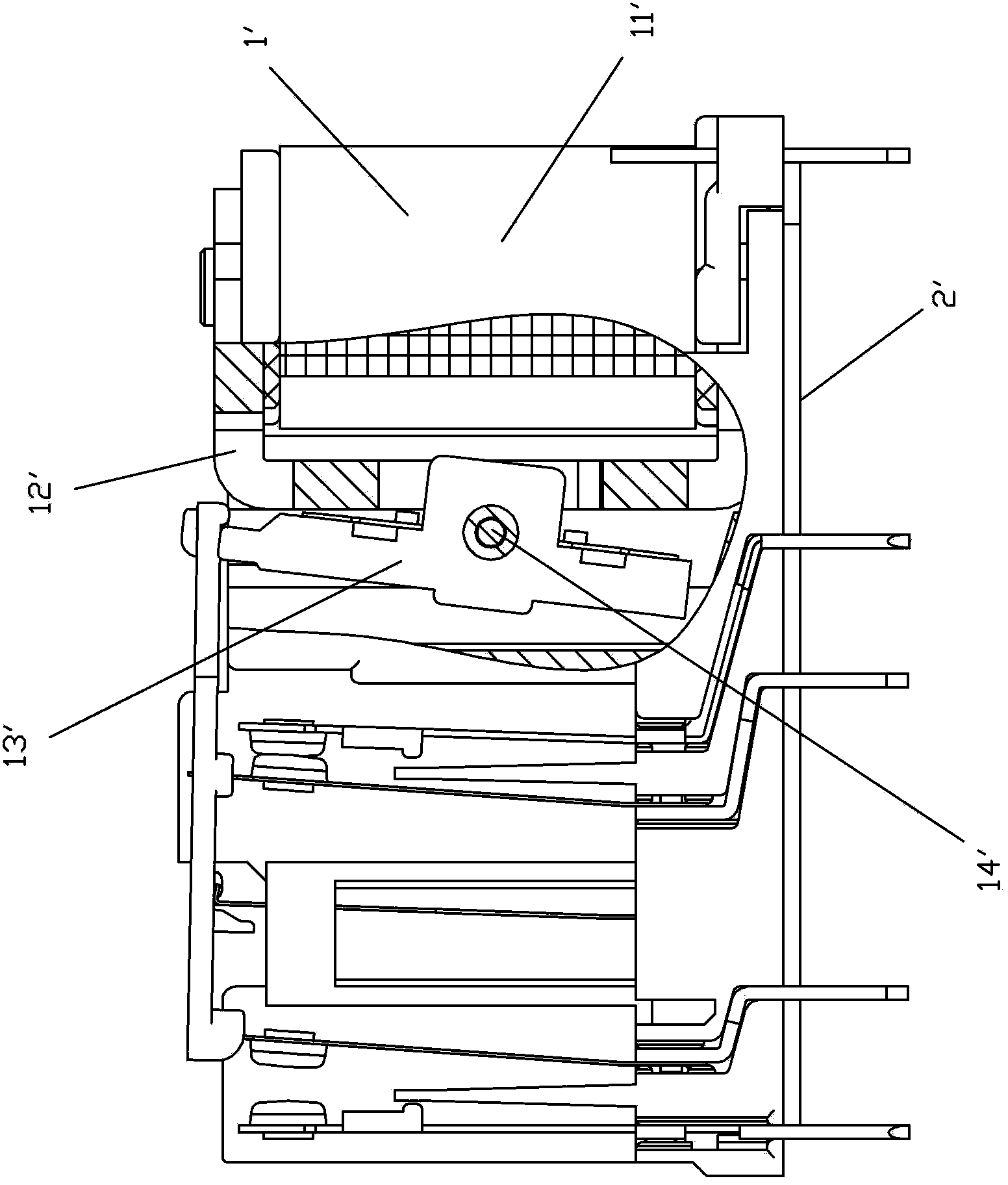

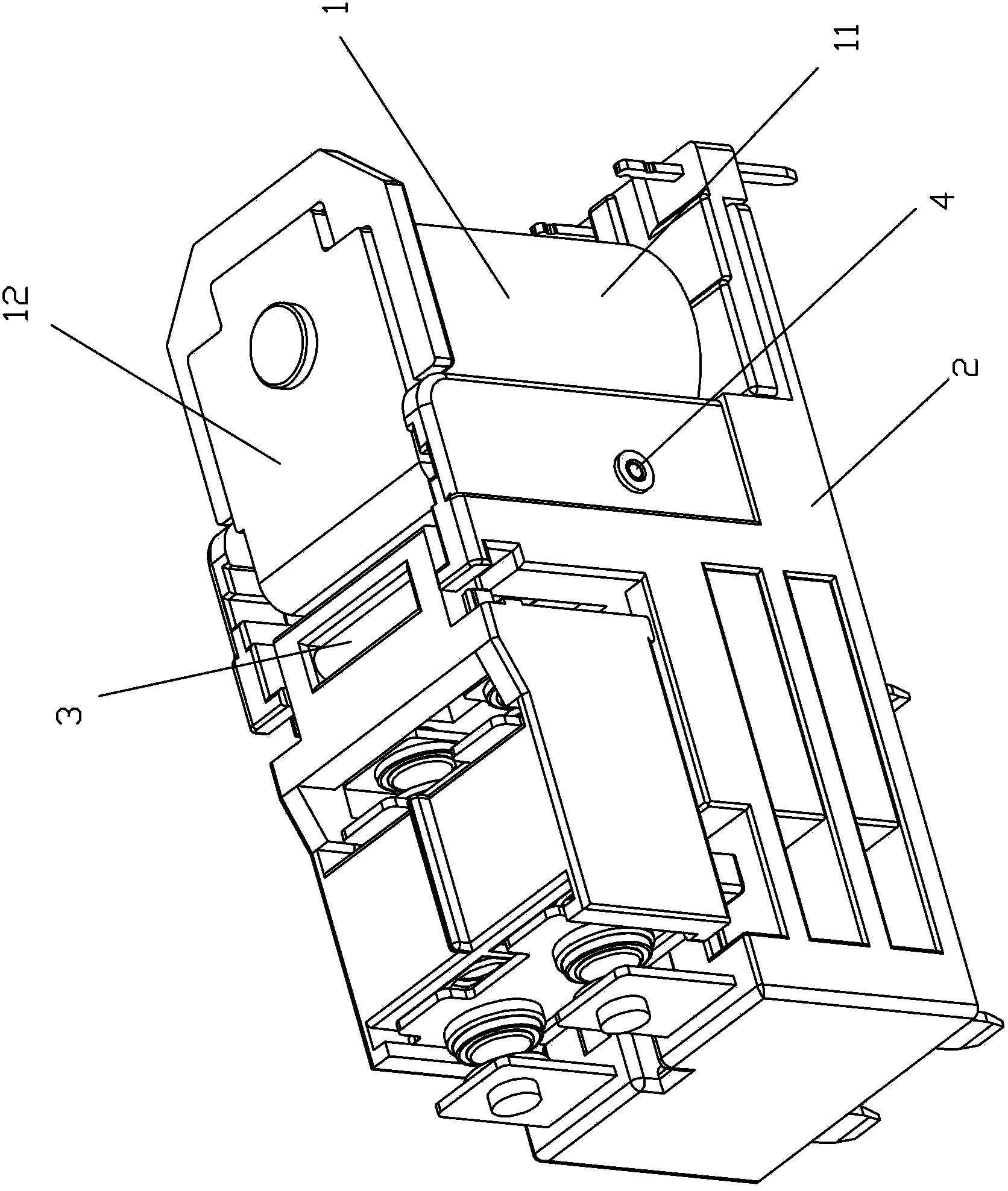

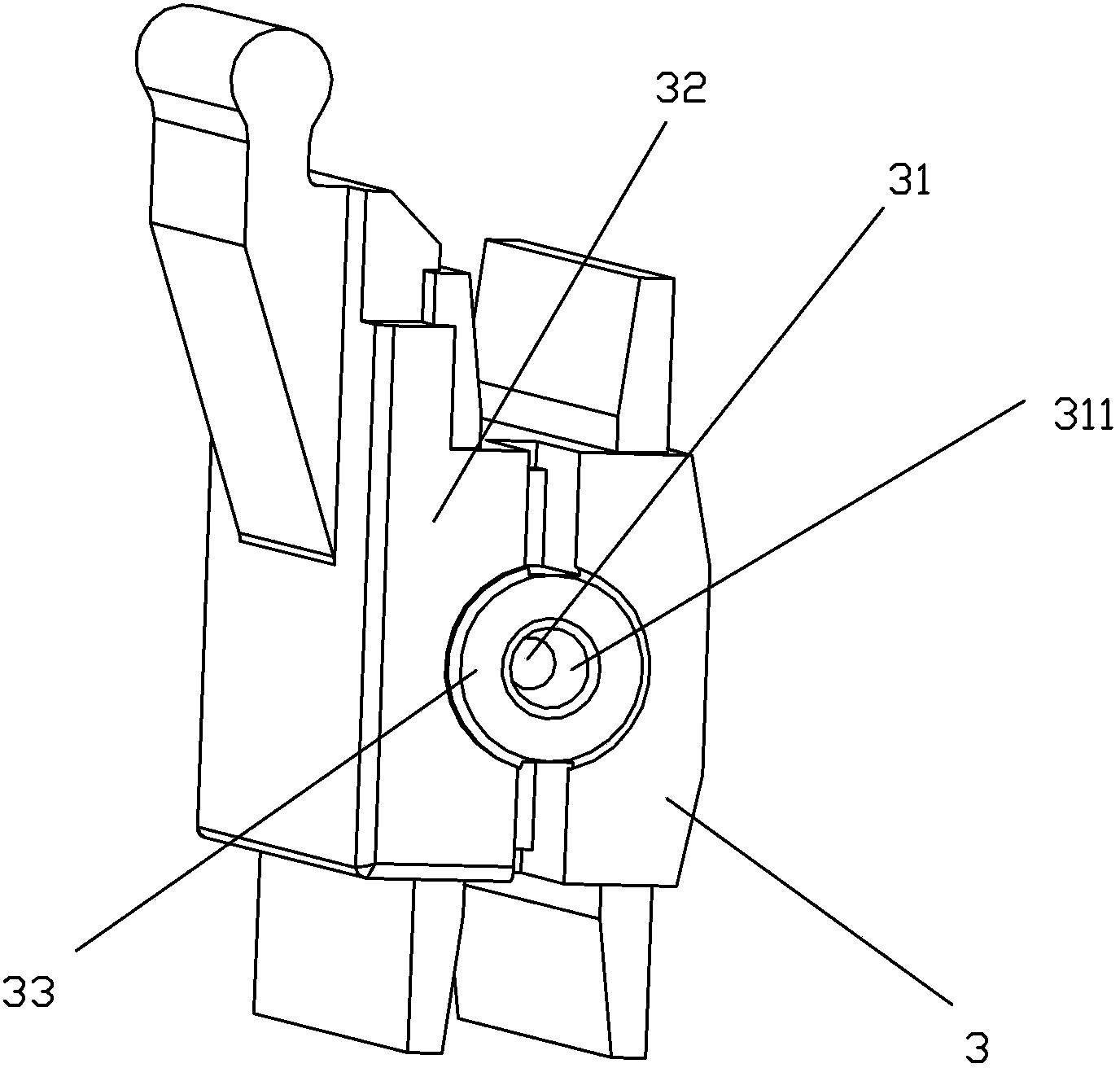

[0029] Examples, see Figure 2 to Figure 11 As shown, an electromagnetic relay of the present invention that is convenient for inserting an armature part includes a magnetic circuit part 1 and a base 2; the magnetic circuit part 1 is installed on the base 2; the magnetic circuit part 1 includes an armature part 3, a coil 11 and a yoke 12, wherein the armature part 3 is installed on the base 2 through a rotating shaft 4; the armature part 3 is provided with a first shaft hole 31 adapted to the rotating shaft, and the first shaft hole 31 penetrates two opposite sides of the armature part The side surface 32; the base 2 is provided with two opposite support parts 21, and the two support parts 21 are respectively provided with a second shaft hole 211 adapted to the rotating shaft; the armature part 3 is fitted between the two support parts 21 of the base , and is positioned on the base 2 through the cooperation of the rotating shaft 4 with the first shaft hole 31 and the second sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com