Design Method of Impeller of High Efficiency, Low Cavitation and No Overload Centrifugal Pump

A centrifugal pump impeller and design method technology, applied to pumps, pump components, mechanical equipment, etc., can solve problems such as low efficiency, poor cavitation performance, and unsatisfactory non-overload characteristics, so as to improve pump efficiency and cavitation performance , Excellent non-overload characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] figure 1 and figure 2The figures shown collectively define the shape of the impeller in the embodiment. The shape of the impeller in this embodiment is the same as that of most centrifugal pump impellers, it has an impeller front cover 2 and an impeller rear cover 4, and is a closed impeller. If there is no impeller front cover plate, that is, it is made into a semi-open or open impeller, which will not affect the implementation of the present invention, because the present invention controls the parameters of the blades 6.

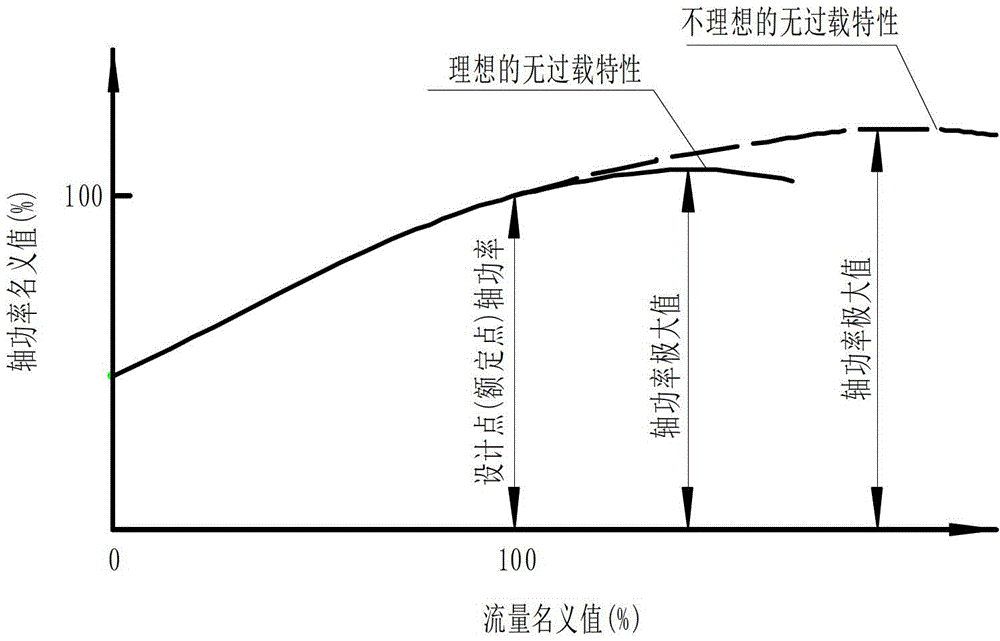

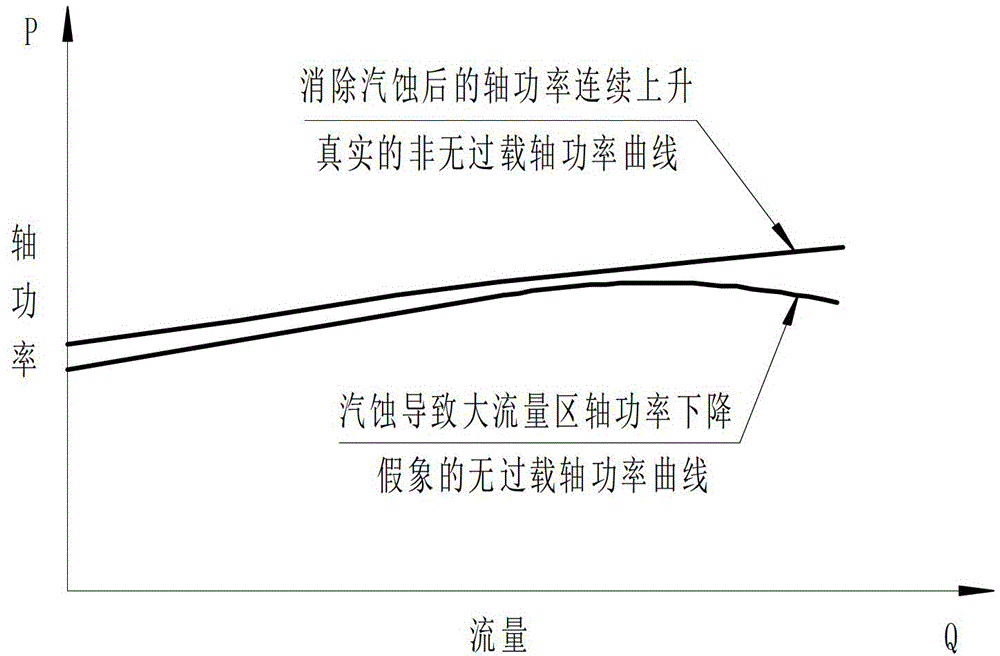

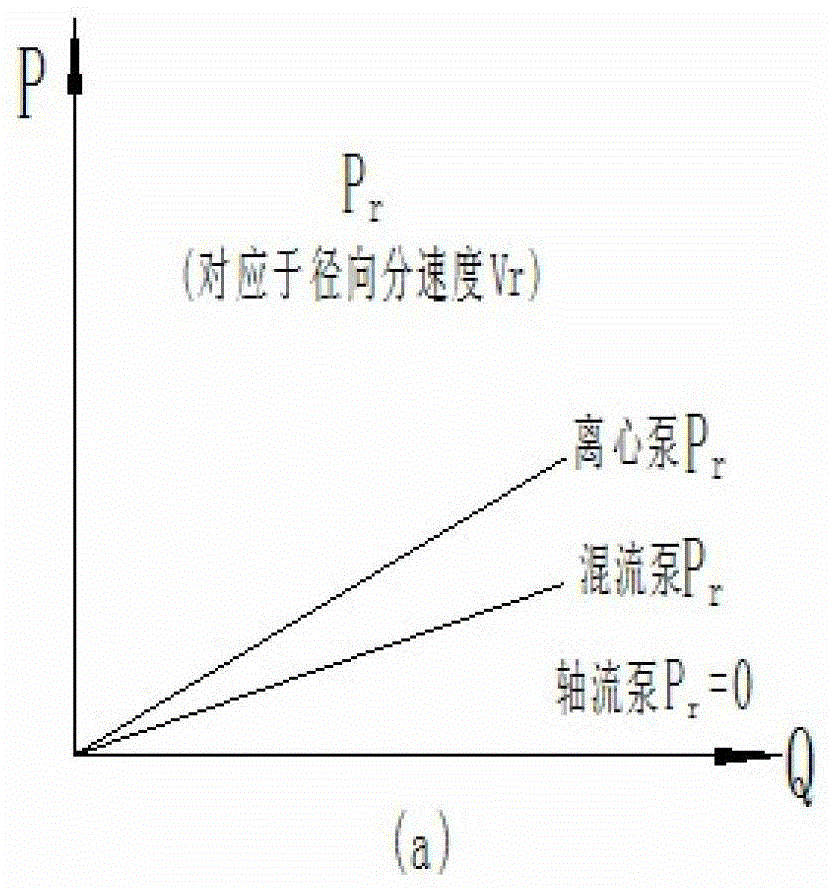

[0050] The present invention adopts the following technical solutions: β 2s =14°~21°, β 2p =10°~16°, Δβ 2 =2°~7°, Z=4~6, θ=155°~210°, Y=1.1~1.5, optimize the geometric parameters of the hydraulic model, so that the centrifugal pump meets the axial power curve of the centrifugal pump after a certain flow point The theoretical conditions of the extreme value, including: optimizing the design of the impeller outlet width 3, the impeller outer di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com