Press finger for a pre-spinning machine

A roving frame and roving technology, applied in textiles and papermaking, etc., can solve the problems of reducing the risk of threading out, unsatisfactory effect, complicated manufacturing technology, etc., and achieve the effect of reliably preventing threading out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

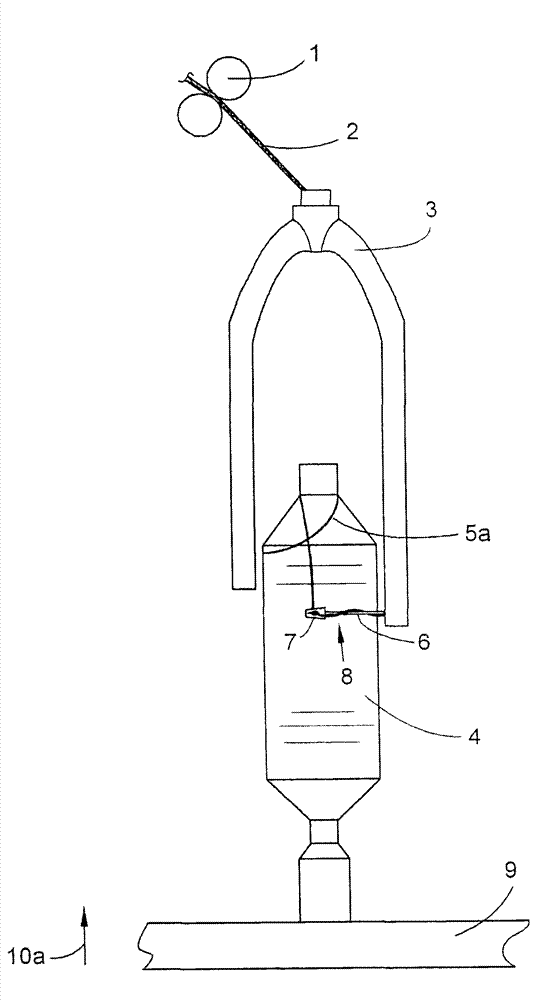

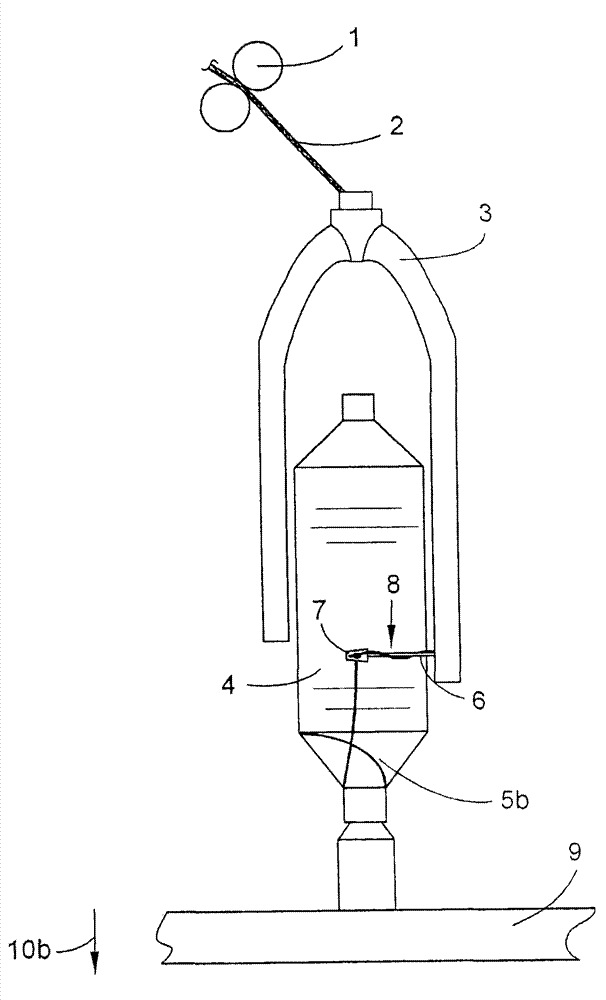

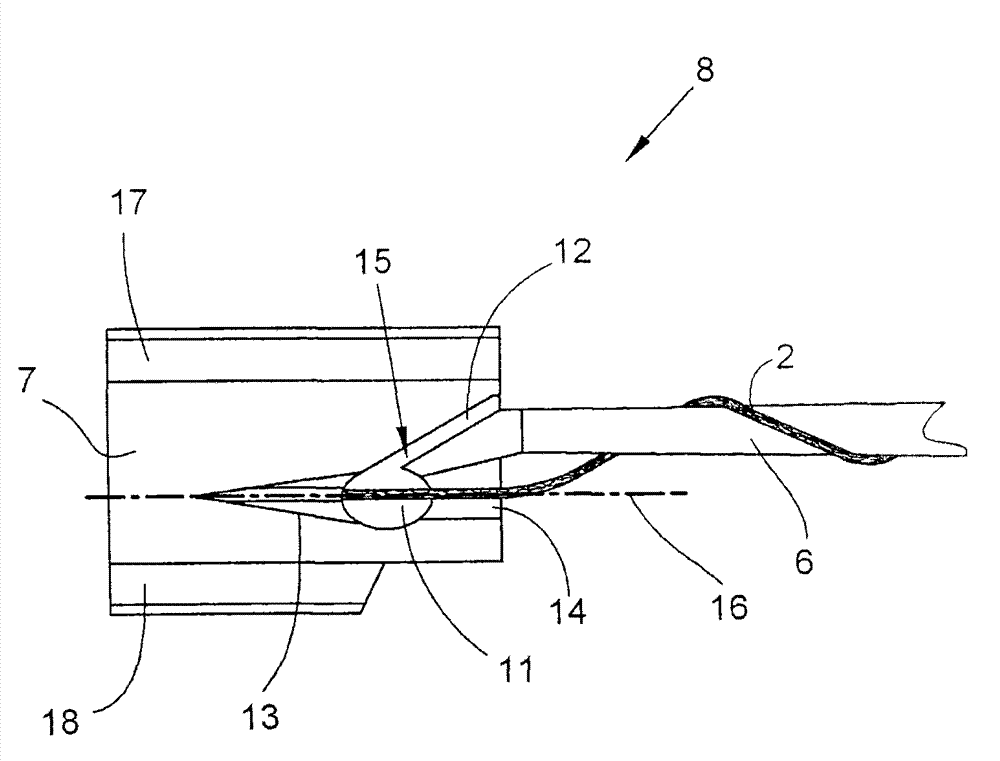

[0026] figure 1 and figure 2 Show the principle structure and working mode of the roving frame. Cooked bar is conveyed by drafting device, and wherein, only shows front roller 1 among the accompanying drawings. The drafted roving 2 is introduced into roving flyers 3, passing through one of the flyers up to its lower end. Presser palm 8 is installed on the flyer. The roving 2 is wrapped around the presser arm 6 and passed through the opening 11 in the presser leaf 7 . The roving bobbins 4 are arranged on the dragon tendons 9 . Longjin 9 can move up and down. The roving 2 obtains the required twist through the rotation of the flyer 3 and the roving bobbin 4, and is wound on the bobbin 4 under the guidance of the presser palm 8. In order to distribute the roving 2 over the axial length of the bobbin 4, the bobbin 4 is then moved up and down by means of the ribs 9.

[0027] When the bobbin 4 has reached the desired diameter, the end rovings 5a, 5b with less twist are reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com