Method for controlling X-Ray punch

A control method and technology for a target drilling machine, applied in the field of control, can solve the problems of no disclosure, complex process types, special materials, etc., and achieve the effects of reducing the probability of errors, simplifying operation steps, and reducing operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

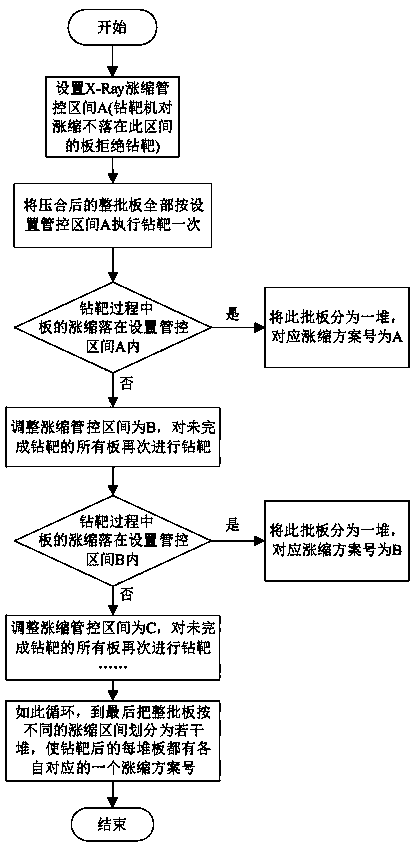

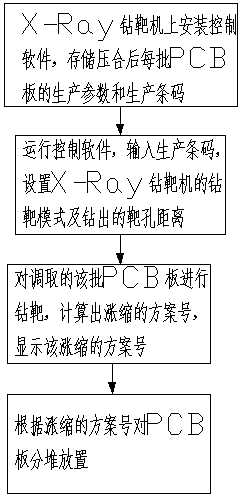

[0023] Such as image 3 As shown, an X-Ray target drilling machine control method includes the following steps,

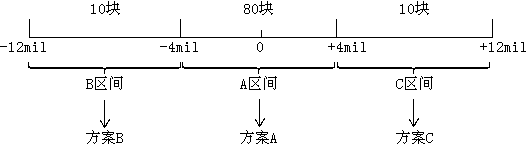

[0024] S1. Install the control software on the X-Ray target drilling machine. The control software is xrayaux.exe software, which stores the production parameters and production barcodes of each batch of PCB boards after lamination. Each batch of PCB boards corresponds to a unique production barcode; the control software is pre-set X-Ray expansion and contraction control interval; Among them, the production parameters are the drawing number, size and target distance of each batch of PCB boards after lamination. The control software pre-sets the X-Ray expansion and contraction control interval as ±0.5mil, and the control interval is in The control software has been set up before shooting, and there is no need for human intervention by the shooting operator. The control interval required by each batch of different PCB boards is the same. First of all, ERP will store...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com