Manufacturing method of heating shoe

A manufacturing method and technology for warming shoes, applied to shoemaking machinery, footwear, shoe soles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

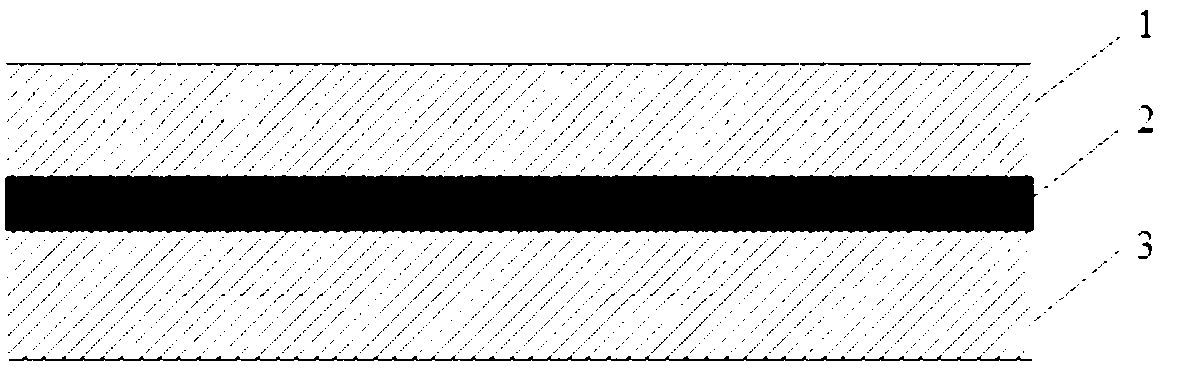

[0013] Such as figure 1 As shown, the heating shoes of the present embodiment are composed of an outer layer 1, an inner layer 2 and a middle layer 3. Both the outer layer 1 and the inner layer 2 are plush fabrics. The middle layer 3 is a soft cable electric heating element laid in a snake shape, and the electric heating element is connected with a small battery placed at the heel.

[0014] The manufacture method of this heating shoe comprises the following steps:

[0015] (1) Cut the inner layer and outer layer of the heating shoes with plush fabric, and sew them separately;

[0016] (2) Lay soft cable-type electric heating elements in the shape of a coil snake on the inner side of the outer layer, and use fixing parts to fix the flexible cable elements;

[0017] (3) Nest the inner layer sewn in step (1) into the outer layer where the electric heating element has been laid, and sew the inner layer and the outer layer together;

[0018] (4) Install a small storage battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com