Deep tillage rotary plow

A technology of plow and rotary plow, applied in the field of deep-plow rotary plow, can solve problems affecting crop yield, soil degradation, and affecting the emergence rate of crop winter wheat, so as to facilitate germination and root growth, increase soil nitrogen content, and realize food production. The effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

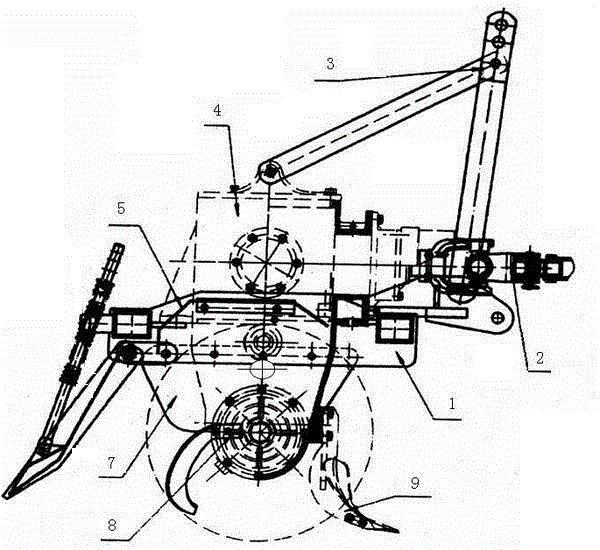

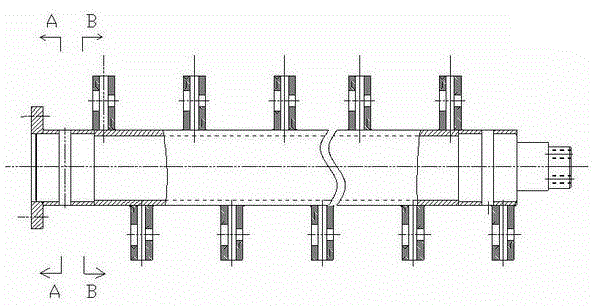

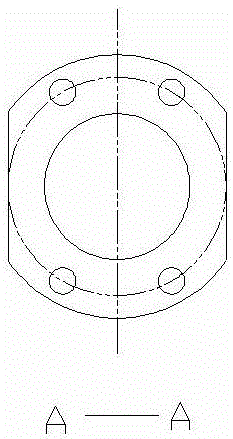

[0016] As shown in the figure, the deep-plow rotary plow consists of a frame assembly 1, a universal joint assembly 2, a suspension frame assembly 3, a gearbox assembly 4, a cutter shaft assembly 8, a machine cover 5, a side plate 7 and The rotary tiller is composed of 9; the middle part of the frame assembly 1 is provided with a gearbox assembly 4; the gearbox assembly 4 is connected with the output shaft at the tail of the tractor through the universal joint assembly 2; the output shaft of the gearbox assembly 4 Drive the cutter shaft assembly 8 to rotate; the rotary tiller blade mounting seat is provided on the cutter shaft assembly 8, and the rotary tiller blade 9 is installed on the cutter shaft assembly 8 through the rotary blade mounting seat; the rotary tiller blade 9 is Deep tillage rotary tiller.

[0017] The deep-plow rotary plow is characterized in that: the deep-plow rotary plow is composed of a handle 9-1, a blade body 9-2 and a cutter head 9-4; wherein the handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com