Wire-harness protection structure

A technology for protecting structures and components, applied in the direction of circuits or fluid pipelines, insulated conductors, cables, etc., can solve the problems of increased workload and increased number of parts, and achieve the effect of easy operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

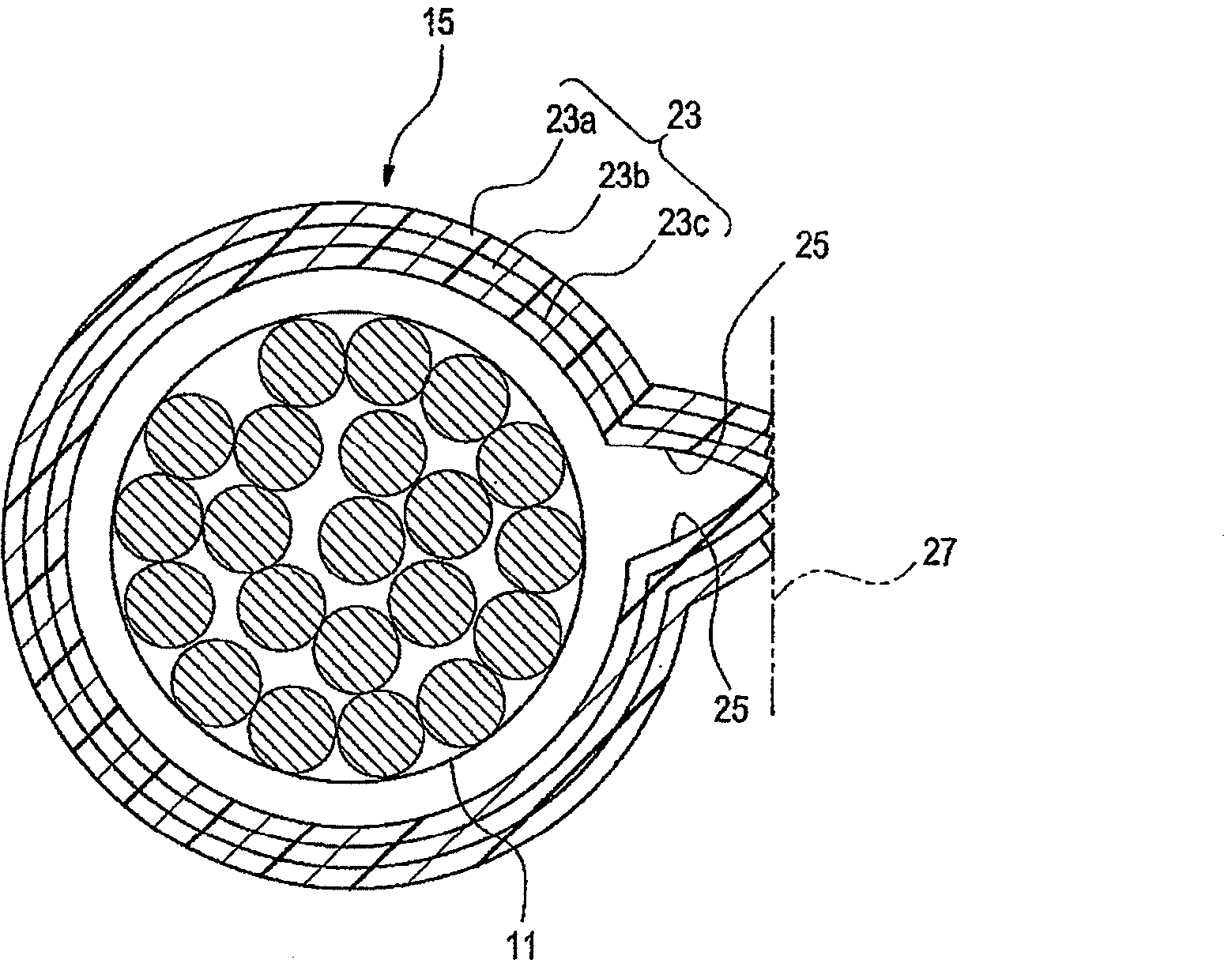

[0037] Exemplary embodiments of the present invention are now described by referring to the accompanying drawings.

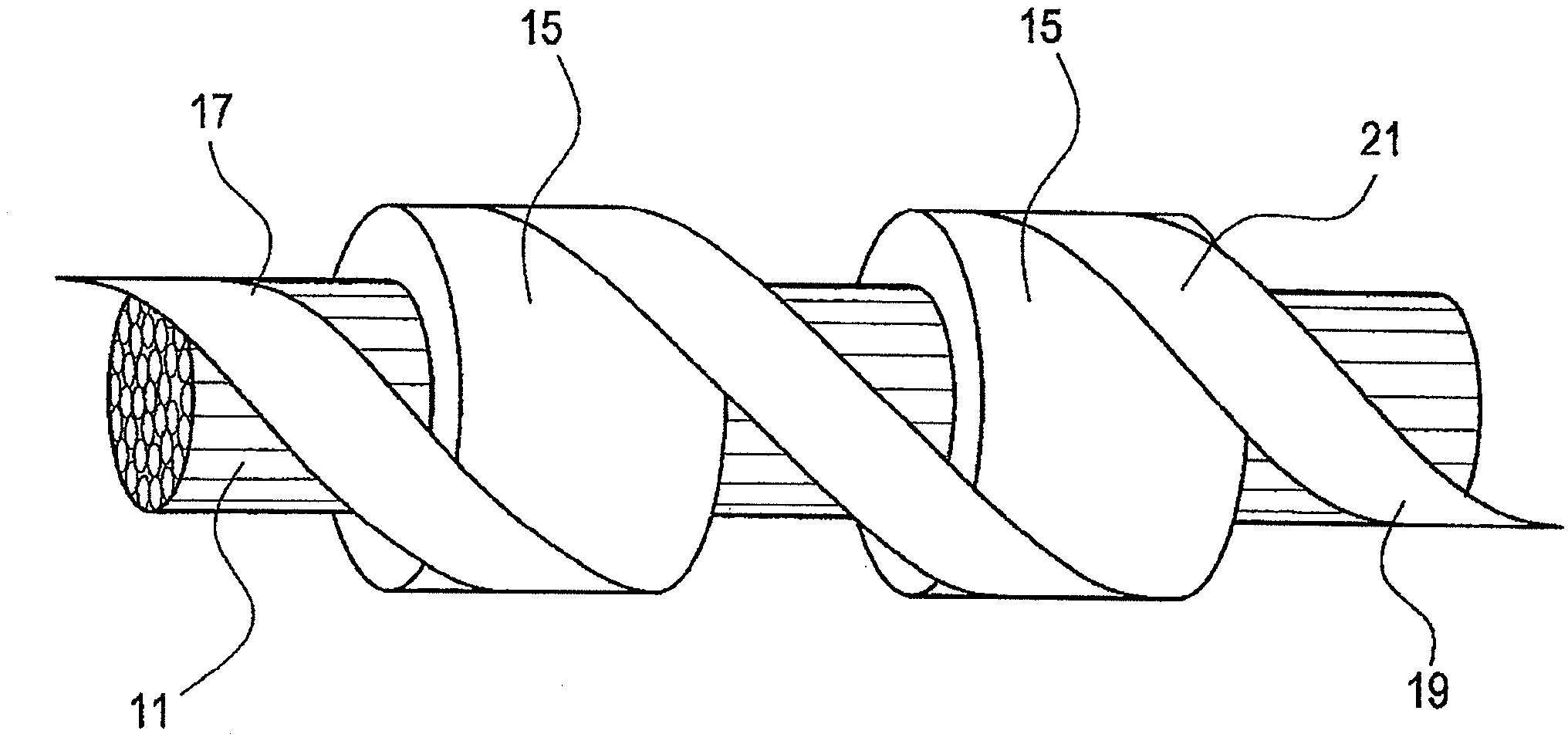

[0038] figure 1 is a perspective view of the appearance of the wire harness protective structure according to the first exemplary embodiment of the present invention.

[0039] This wire harness protection structure serves to protect a predetermined portion of the wire harness 11 from interference by other members. The wire harness 11 may be a single wire or a bundle of multiple wires. This wire harness protection structure includes: a protection member 15 that covers the outer periphery in a predetermined portion of the wire harness 11 ; and an adhesive tape 21 for fixing that fixes the protection member 15 .

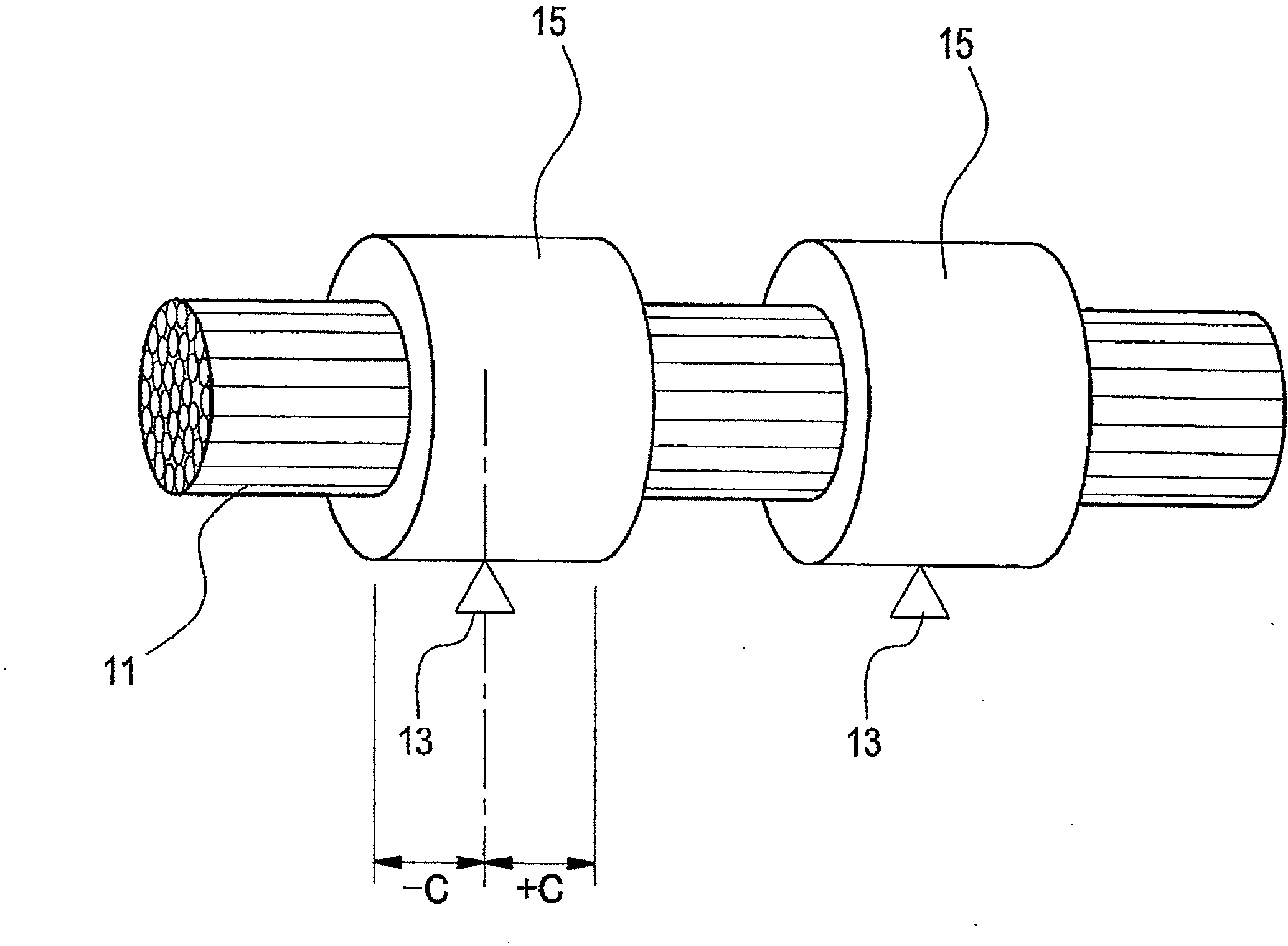

[0040] figure 2 is a perspective view of the wire harness before the adhesive tape for fixing is wound around the wire harness.

[0041] The wire harness protection structure may have a predetermined portion or predetermined portions to be protected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com