Rope pressing device of rope descent control device

A rope-pressing device and descending device technology, which is applied in life-saving equipment, building rescue, etc., can solve the problems of poor rope-pressing effect and small corner of the rope-pressing bag, so as to improve the rope-pressing effect and enlarge the rope-pressing bag corner effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

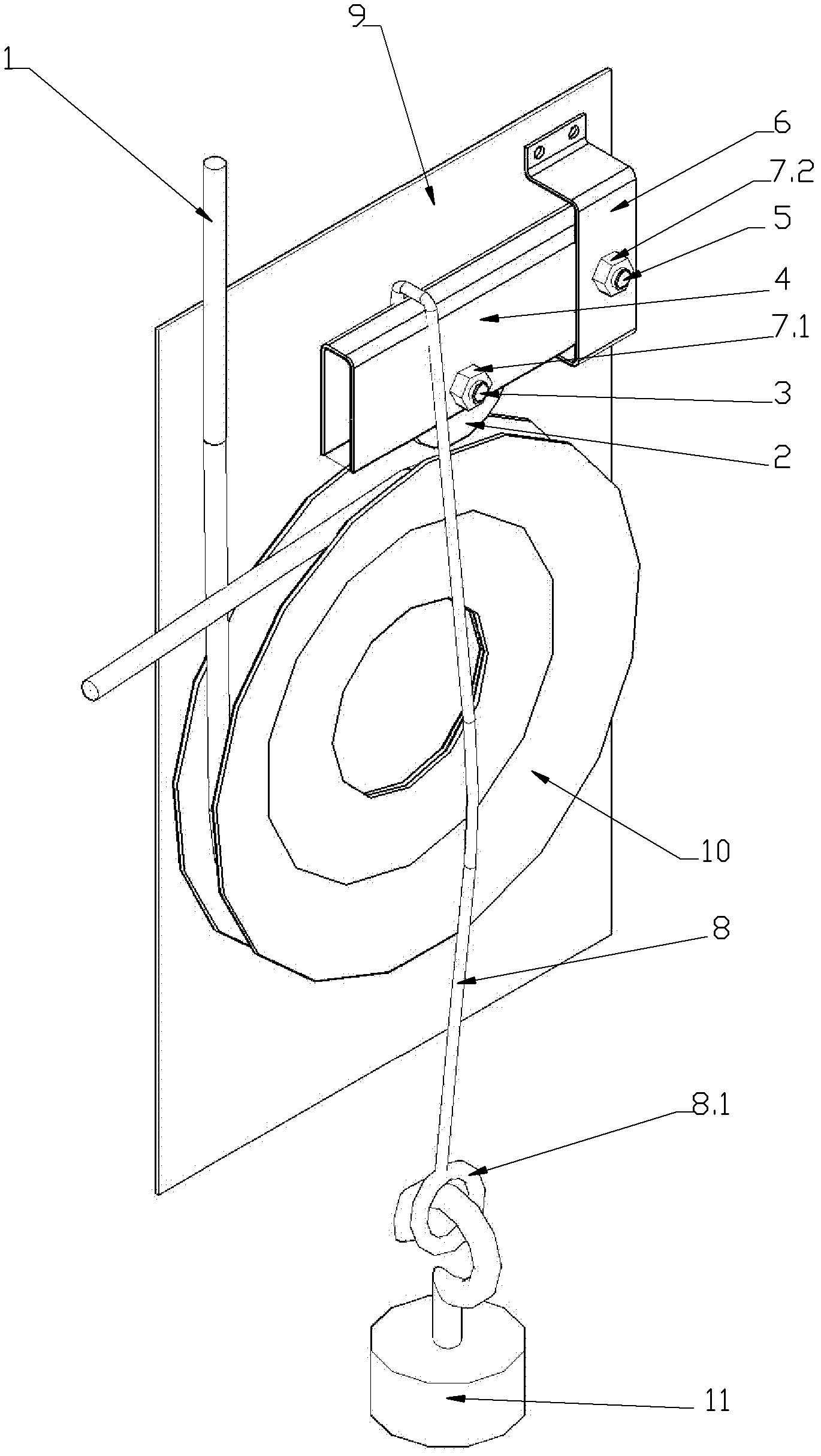

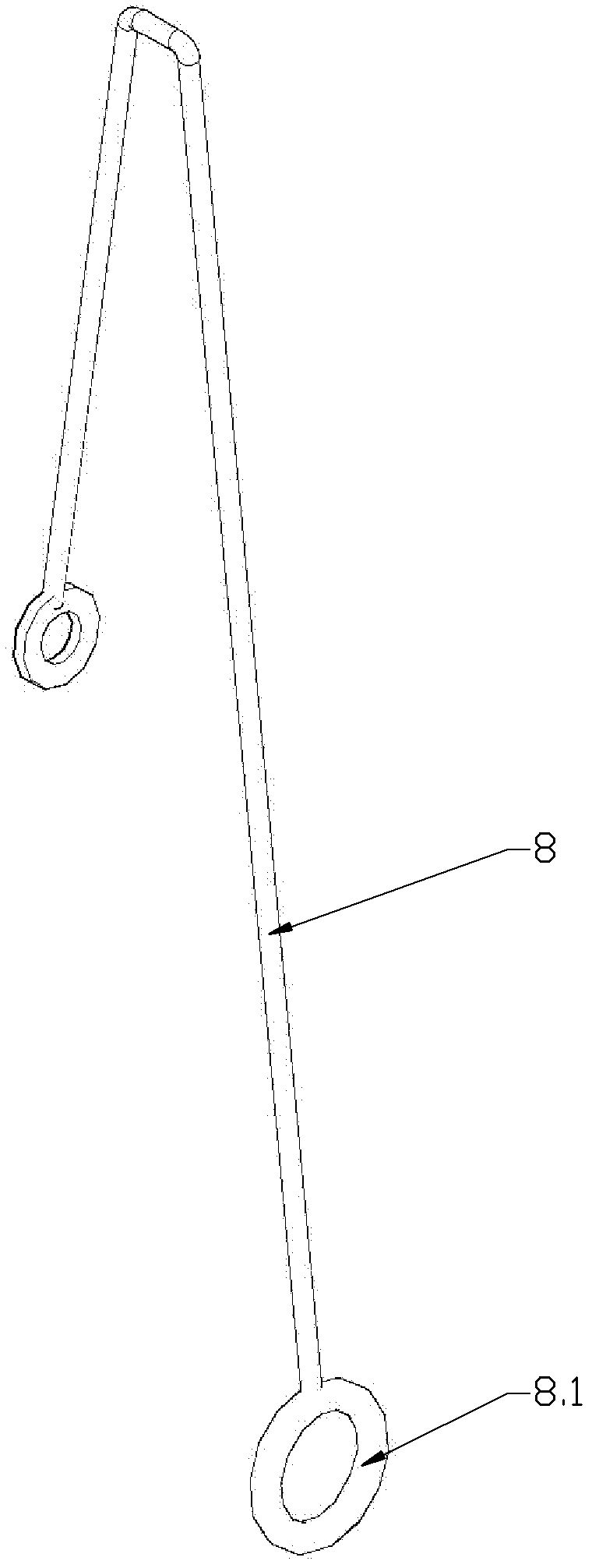

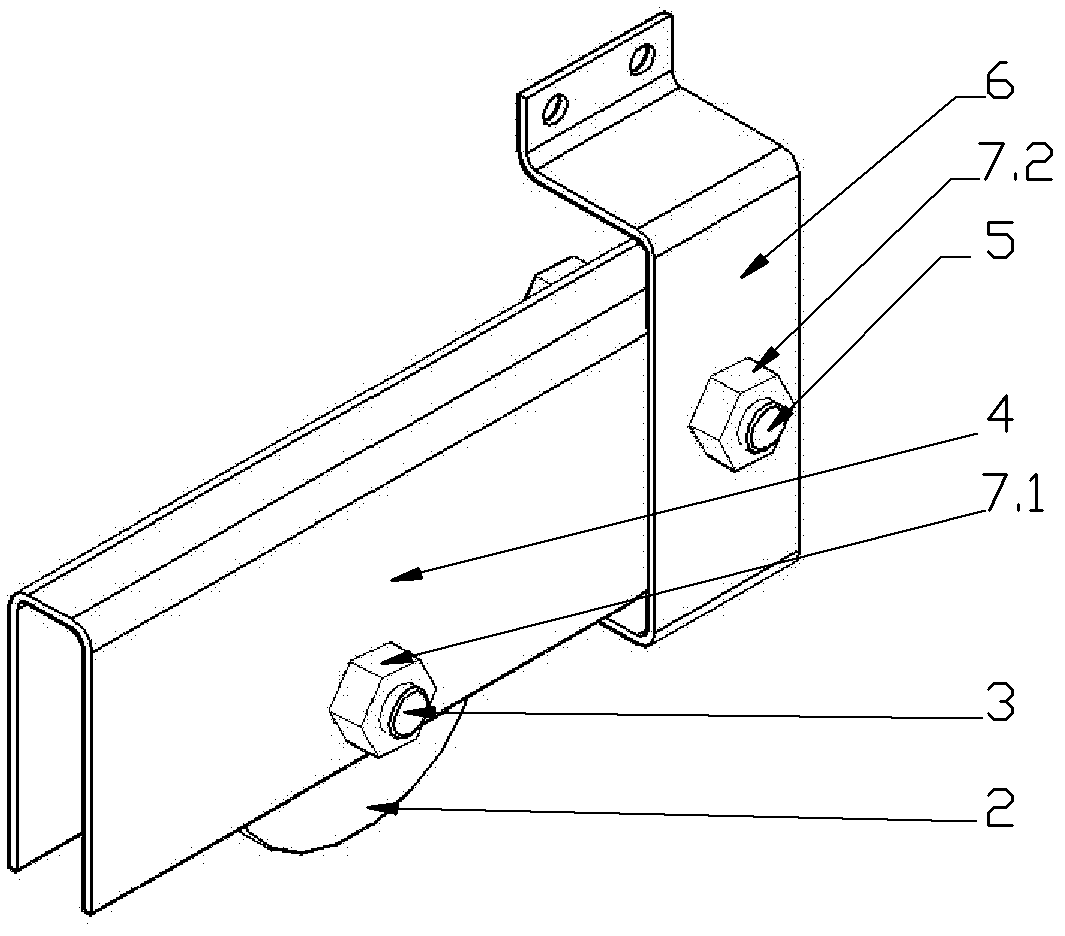

[0021] figure 1 , figure 2 , image 3 It is a structural schematic diagram of the first embodiment of the present invention, wherein figure 1 is a stereogram, figure 2 , image 3 Schematic diagram of the component structure. As shown in the figure, this example proposes a rope-pressing device for a rope descending device, which mainly includes a rope 1, a rope-pressing wheel 2, a wheel shaft 3, a wheel shaft seat 4, a support shaft 5, a support shaft seat 6, a shaft end fixing member 7.1, 7.2. Compression piece 8, machine body 9, rope winding wheel 10, rope 1 is wound on rope winding wheel 10, rope pressing wheel 2 is installed on wheel shaft 3 and fixed on wheel shaft seat 4 through shaft end fixing piece 7.1 (Note: The other end of the shaft end fixture on the wheel shaft 3 is not shown in the figure), and the axle seat 4.1 is installed on the support shaft seat 6 through the support shaft 5 and fixed on the body 9 by the shaft end fixture 7.2. figure 2 As shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com