Workpiece Arrangement Conveyor

A technology for arranging conveying devices and workpieces, applied to conveyors, vibrating conveyors, conveyor objects, etc., can solve problems such as direct input of workpieces inappropriate posture, reduced production line efficiency, transportation, etc., and achieve the effect of reducing posture change errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

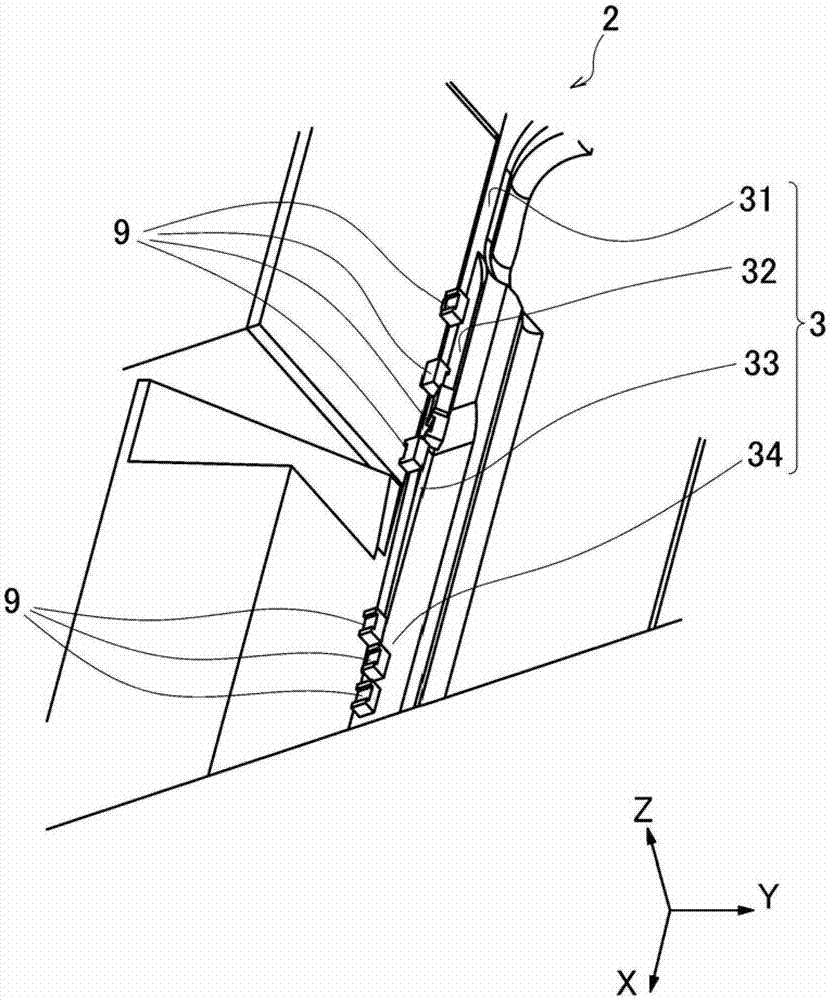

[0037] Such as figure 1As shown, the workpiece alignment and conveyance device 1 according to the first embodiment is configured to vibrate the conveyance table 2 on which the conveyance path 3 is formed, and can be conveyed and placed on the conveyance table 2 in the W direction in the drawing by utilizing the vibration of the conveyance table 2 . Workpieces 9-9 above.

[0038] Here, the conveying direction of the workpiece 9 is defined as the W direction, the horizontal direction substantially the same as the conveying direction of the workpiece 9 is defined as the X direction, and the vertically upward direction is defined as the Z direction as the coordinate axes shown in the figure. direction, the inward direction of the paper surface orthogonal to the X direction and the Z direction is defined as the Y direction.

[0039] Hereinafter, the specific structure of the workpiece alignment conveyance apparatus 1 of this embodiment is demonstrated using each direction defined ...

no. 2 Embodiment approach

[0103] Figure 12 It is a perspective view showing the vicinity of the junction J1 ( 34 ) of the workpiece alignment and conveyance device 1 according to the first embodiment, Figure 13 It is a perspective view showing the vicinity of the junction J2 ( 134 ) of the workpiece array conveyance device 101 according to the second embodiment of the present invention.

[0104] The workpiece array conveyance apparatus 101 of the second embodiment is different from the workpiece array conveyance apparatus 1 of the first embodiment only in the form of the confluence part J1 ( J2 ), and other parts are the same as the workpiece array conveyance apparatus 101 of the first embodiment. 1 is the same. Therefore, the same reference numerals are assigned to the same parts as those in the first embodiment, and descriptions of parts other than the junction J2 are omitted. Additionally, if Figure 12 and Figure 13 As shown, the lengths in the transport direction of the junction J1 of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com