Self-inflating tire and pressure regulator

一种自充气轮胎、调节器的技术,应用在轮胎测量、轮胎零部件、车轮等方向,能够解决车辆制动和操纵性能降低、轮胎寿命降低、燃料经济性降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

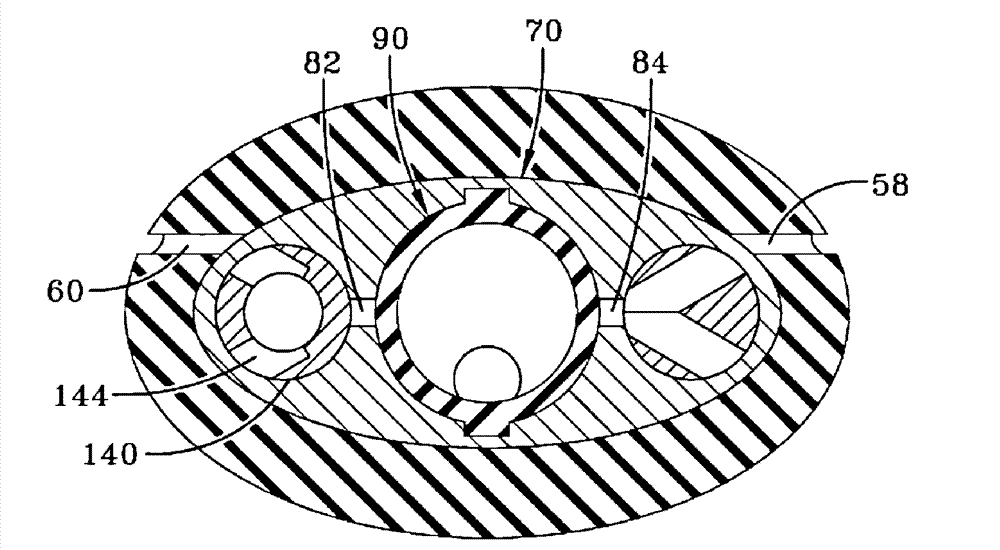

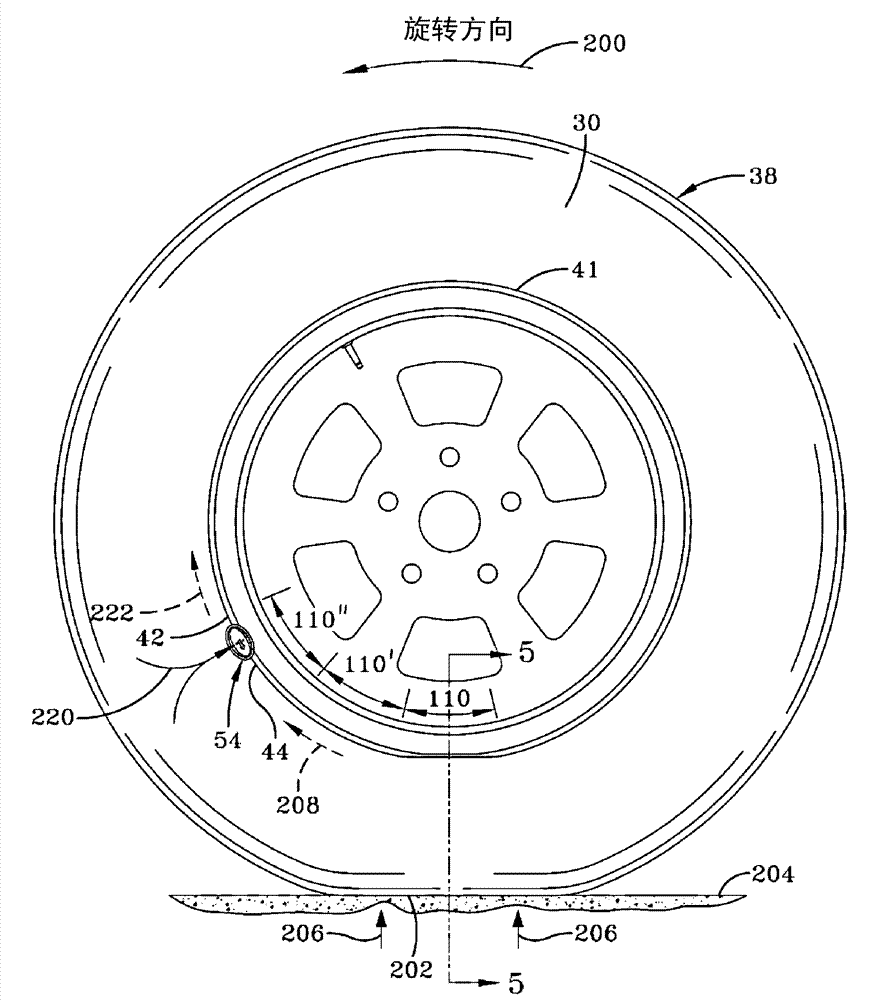

[0046] Referring to FIGS. 1 and 5 , the tire assembly 10 includes a tire 12 , a reversible peristaltic pump assembly 14 and a tire rim 16 . The tire is mounted to a pair of rim mounting surfaces 18 , 20 adjacent outer rim flanges 22 , 24 in a conventional manner. The outer rim flanges 22 , 24 have an outer rim surface 26 . As shown, the annular rim body 28 connects the rim flanges 22, 24 and supports the tire assembly. The tire is of conventional construction having a pair of sidewalls 30 , 32 extending from opposing bead regions 34 , 36 to a crown or tire tread region 38 . The tire and rim enclose the tire cavity 40 .

[0047] As shown in Figures 1, 2 and 3, the peristaltic pump assembly 14 comprises a pump 41 mounted in a passageway 43 in the sidewall region of the tire, preferably adjacent to the bead region. This air channel 43 may be molded into the sidewall of the tire during the vulcanization process or during the molding process after vulcanization hardening. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com