Balance trunnion type connection rod valve spool

A technology of trunnions and spools, applied to valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as seal wear and thermal effects, and achieve the effects of increasing frictional contact area, increasing surface area, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

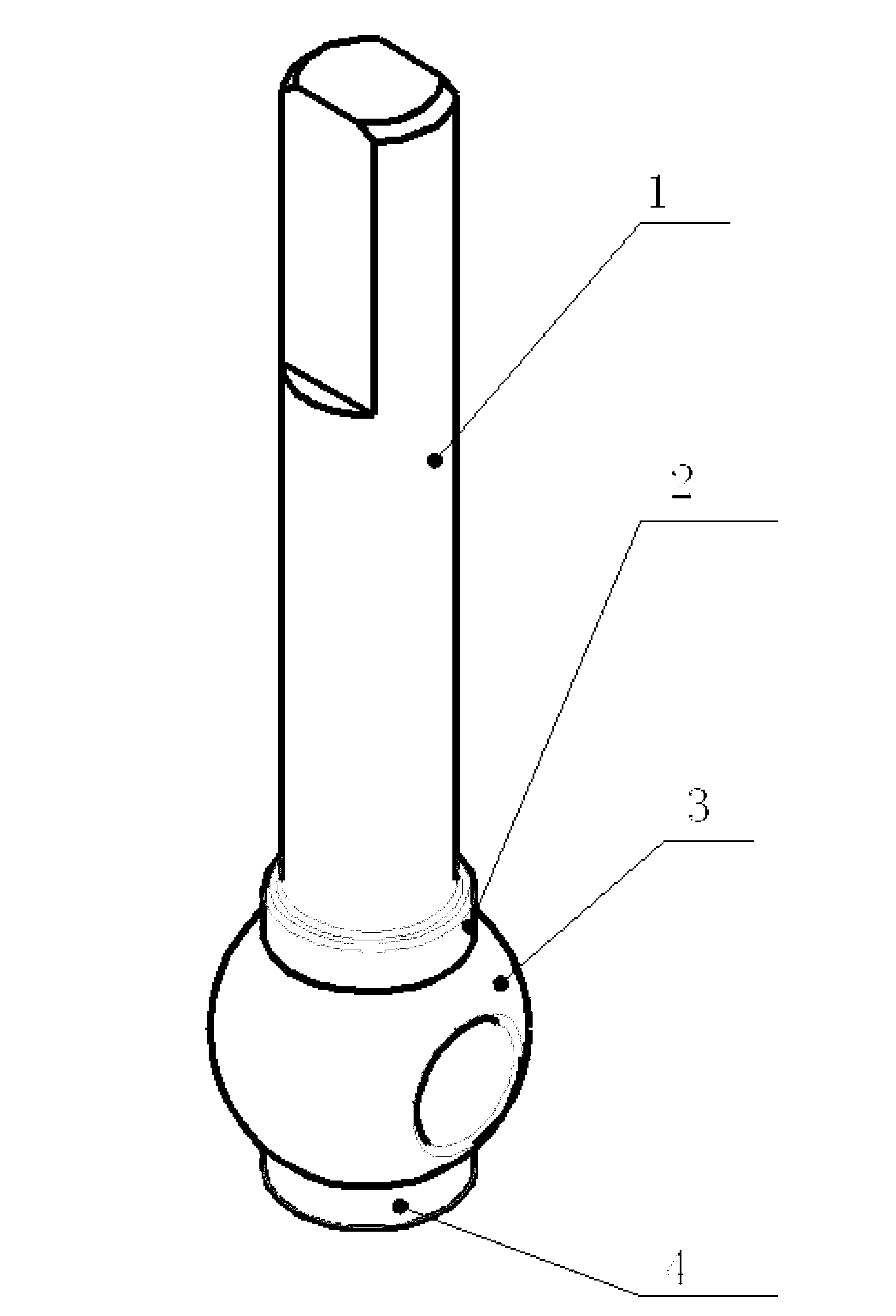

[0013] This embodiment provides a balanced trunnion type connecting rod valve core, such as figure 1 As shown, it includes a cylindrical valve stem 1 and a spherical valve core 3 connected together; an upper trunnion 2 is arranged between the valve stem 1 and the valve core 3, and the upper trunnion 2 is cylindrical, and the diameter of the upper trunnion 2 is larger than that of the valve. The diameter of the rod 1 is smaller than the diameter of the cross-section of the valve core 3; the bottom of the valve core 3 is provided with a lower trunnion 4 symmetrical to the upper trunnion 2, the valve stem part 1, the upper trunnion 2, the valve core 3 and the lower trunnion 4 axes lie on the same straight line.

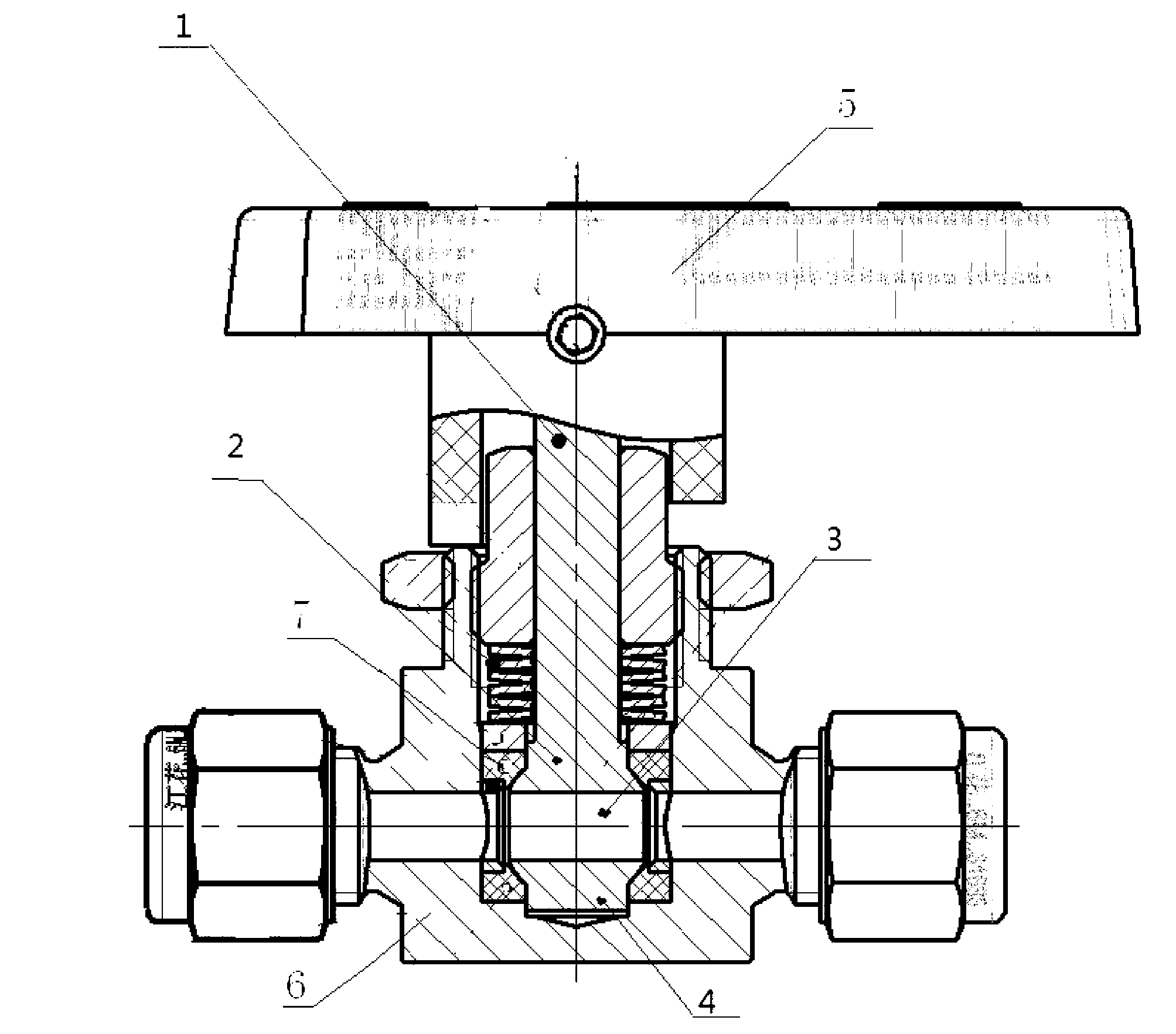

[0014] Such as figure 2 As shown, since this technical solution adopts the design of the balanced trunnion connecting rod valve core, the upper trunnion 2 and the lower trunnion 4 are added without increasing the diameter of the valve stem 1. Large, this improvement g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com