Measuring element, force sensor and measuring assembly for measuring forces

A technology of force measuring sensor and measuring element, applied in the direction of measuring force, force/torque/work measuring instrument, measuring device, etc. Effects of material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

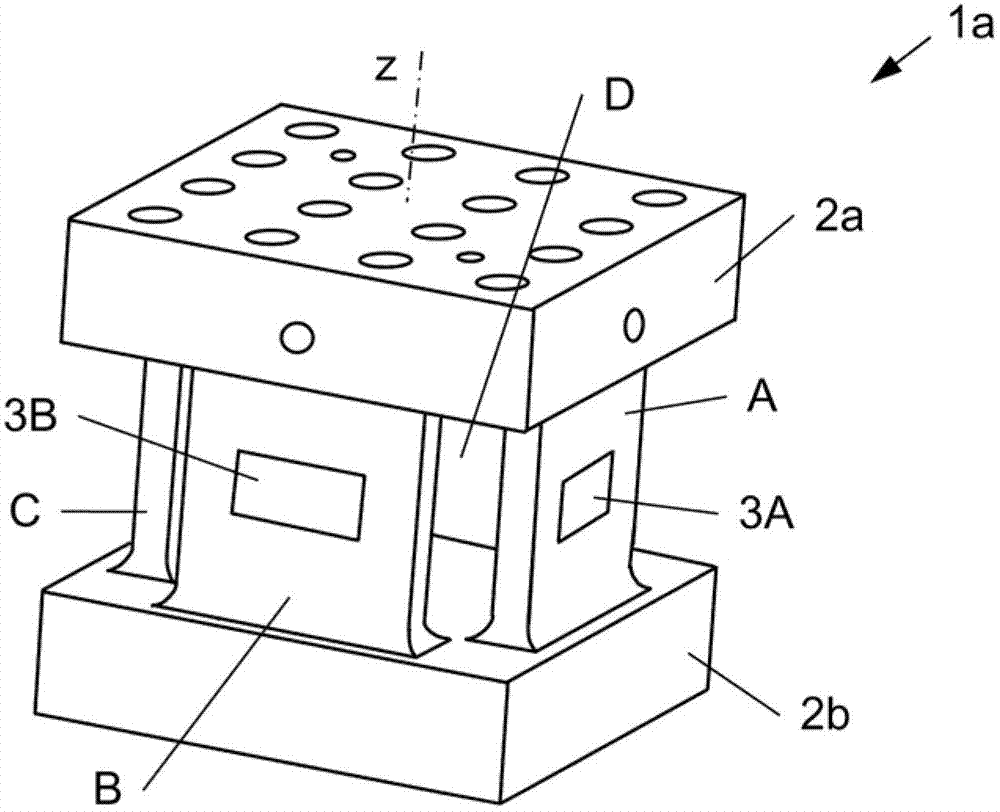

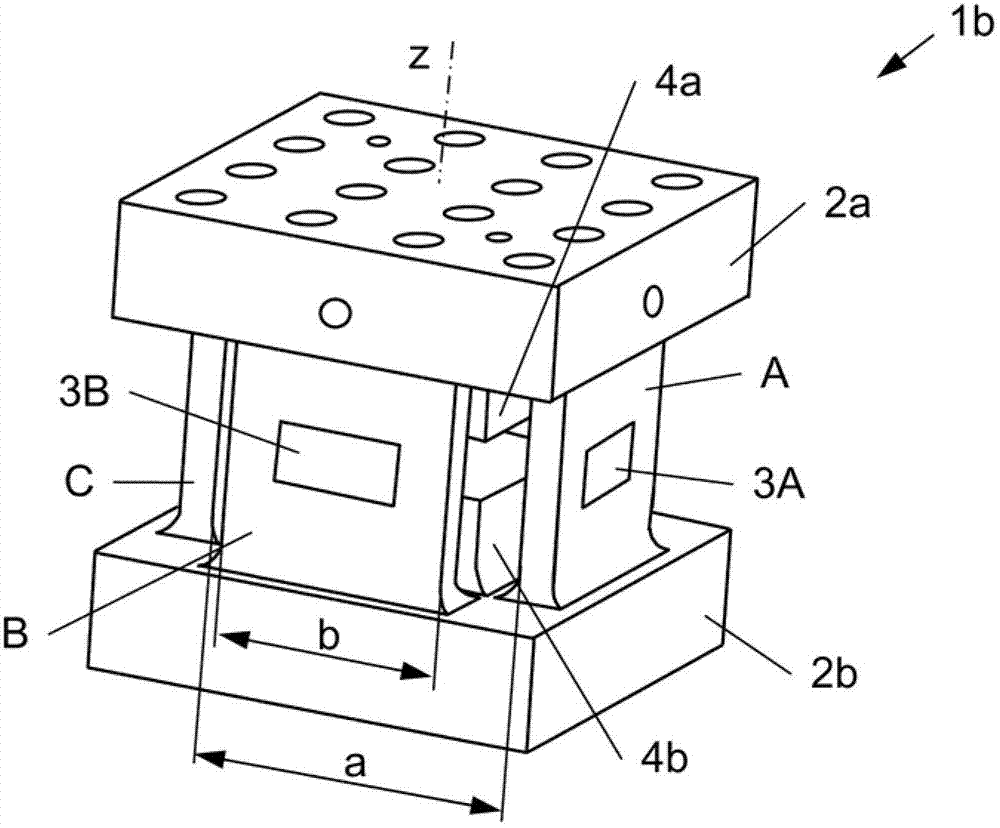

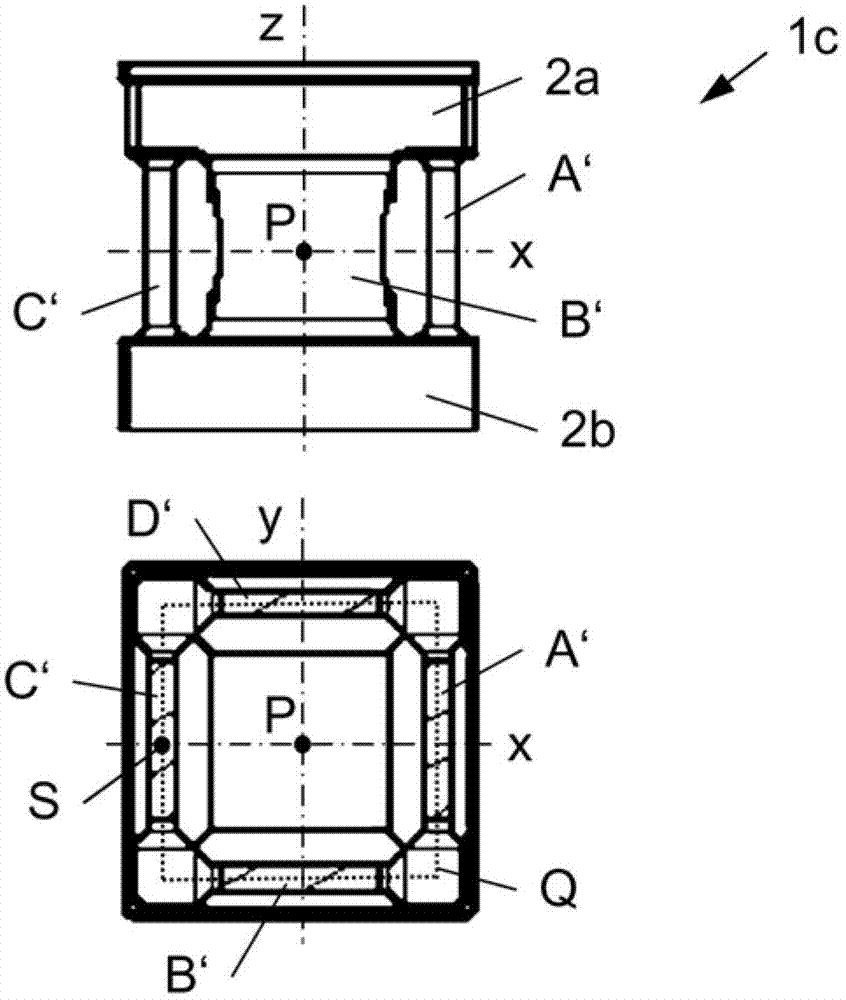

[0061] figure 1 A first example of a measuring element 1a for force measurement is shown, comprising two mutually spaced apart cores 2a, 2b each having at least one mounting surface for introducing the force to be measured, and four identical The webs A..D spaced apart from each other, oriented along the longitudinal axis z, are arranged in a square and connect the two cores 2a, 2b at connecting surfaces spaced apart along the longitudinal axis. Load cells 3A..3D are arranged on each of said webs A..D. Otherwise, the measuring cell 1a does not comprise a further load cell.

[0062] exist figure 1 In the example specifically shown in , the core parts 2a, 2b are identical and have mounting surfaces parallel to each other, and a plurality of mounting holes are provided in the mounting surfaces. In this example, the webs A..D of the measuring cell 1 a are formed as prisms, which are oriented parallel to the longitudinal axis z and have a rectangular cross-section. Furthermore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com