Flow automatic control multifunctional coarse cereal rice mill

An automatic control device and multi-functional technology, applied in grain processing, application, grain pod removal, etc., can solve the problems of low rice milling quality, insufficient feeding, repetitive labor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

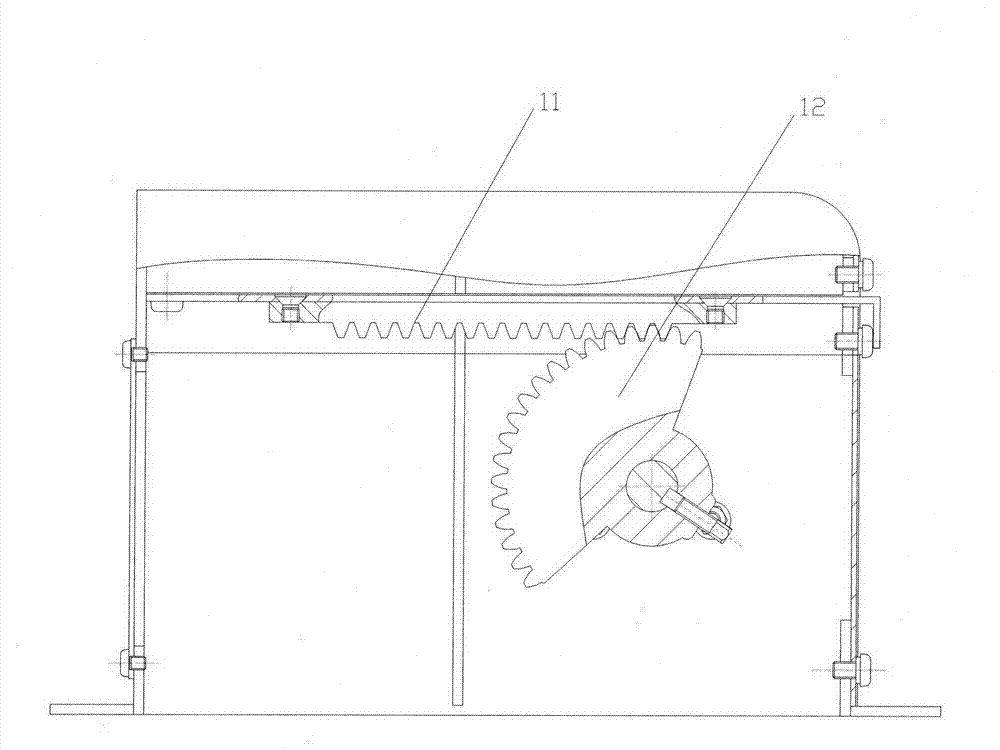

[0018] Such as figure 1 As shown, the flow automatic control type multi-functional miscellaneous grain rice mill is composed of a feed hopper 1, a whitening chamber 2, a frame 3, a control box 4 and a three-phase asynchronous motor 5, and the feed hopper 1 is fixed on the frame 3 on the upper left, the whitening chamber 2 is located inside the frame 3, the control box 4 is fixed on the upper right of the frame 3, and the three-phase asynchronous motor 5 is fixed on the ground. The feeding hopper 1 is equipped with an automatic flow control device, which adopts a rack and pinion structure, and the feeding speed is controlled by PLC; the whitening chamber 2 can be equipped with sand rollers or iron rollers; the whitening chamber 2 is also equipped with rice knife gap adjustment The device is used to adjust the gap between the rice knife and the roller.

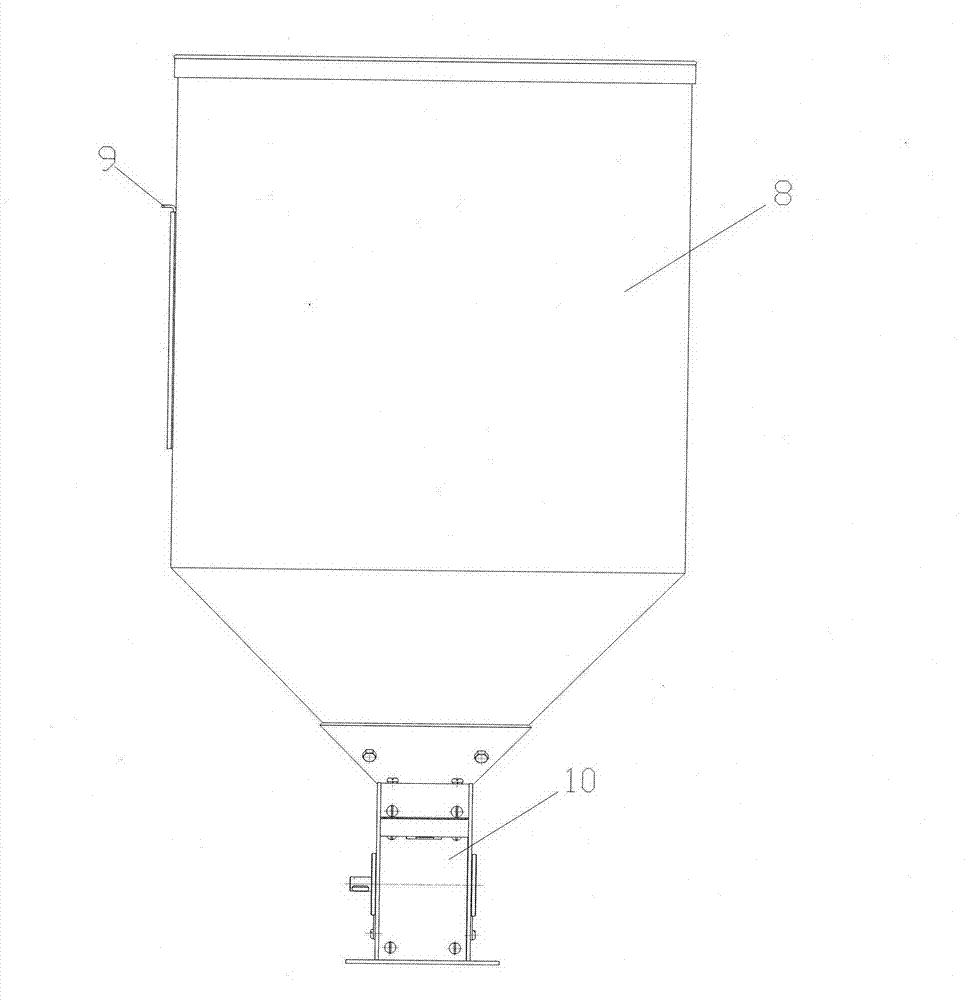

[0019] Such as figure 2 As shown, the feed hopper 1 is mainly composed of a hopper 8, a door 9, a feed hopper seat 10 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com