Automatic feeder for electrode plates

A technology of automatic feeding and electrode sheet, which is applied to conveyor objects, transportation and packaging. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The electrode sheet automatic feeder provided by the present invention will be further described in detail below through specific examples.

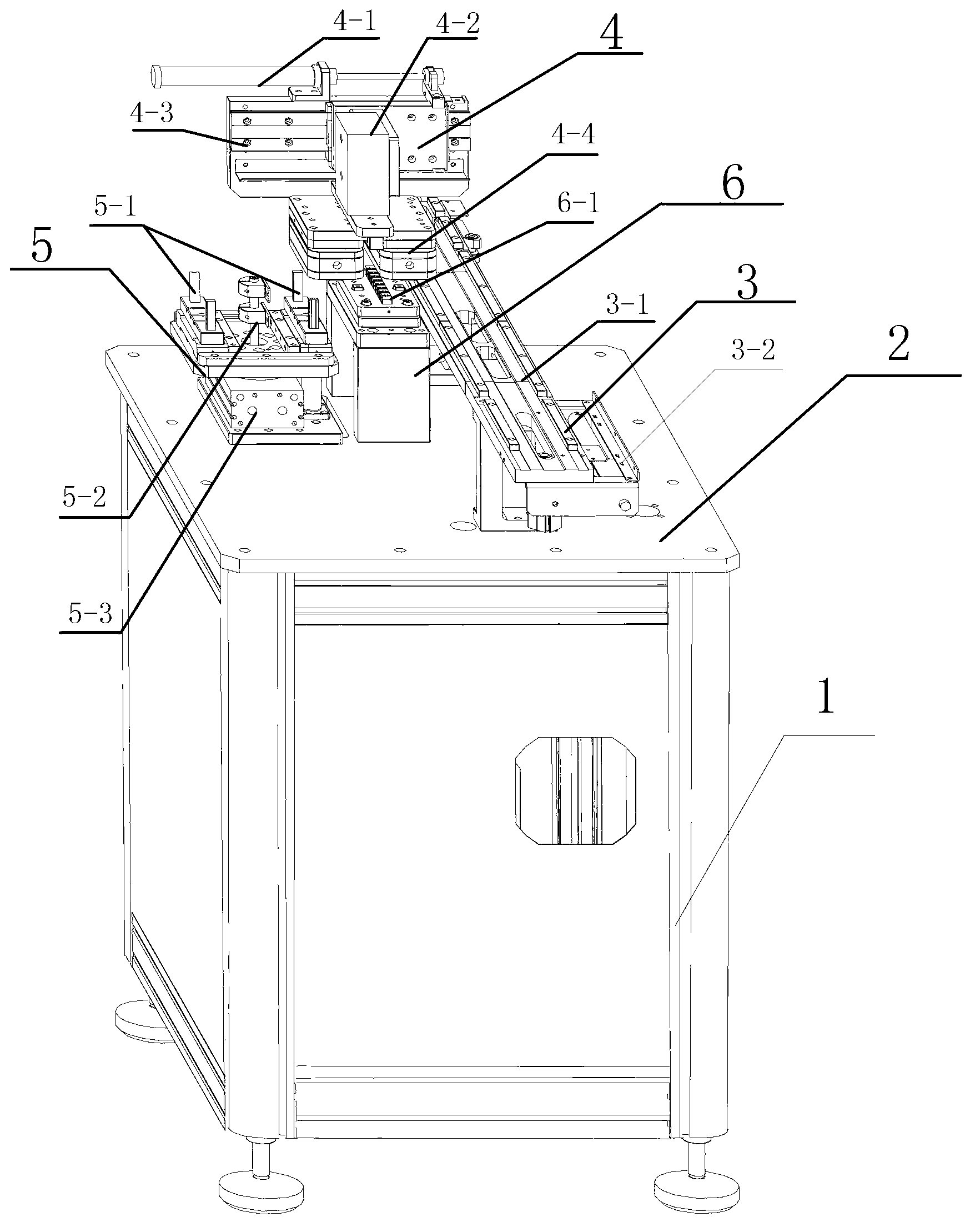

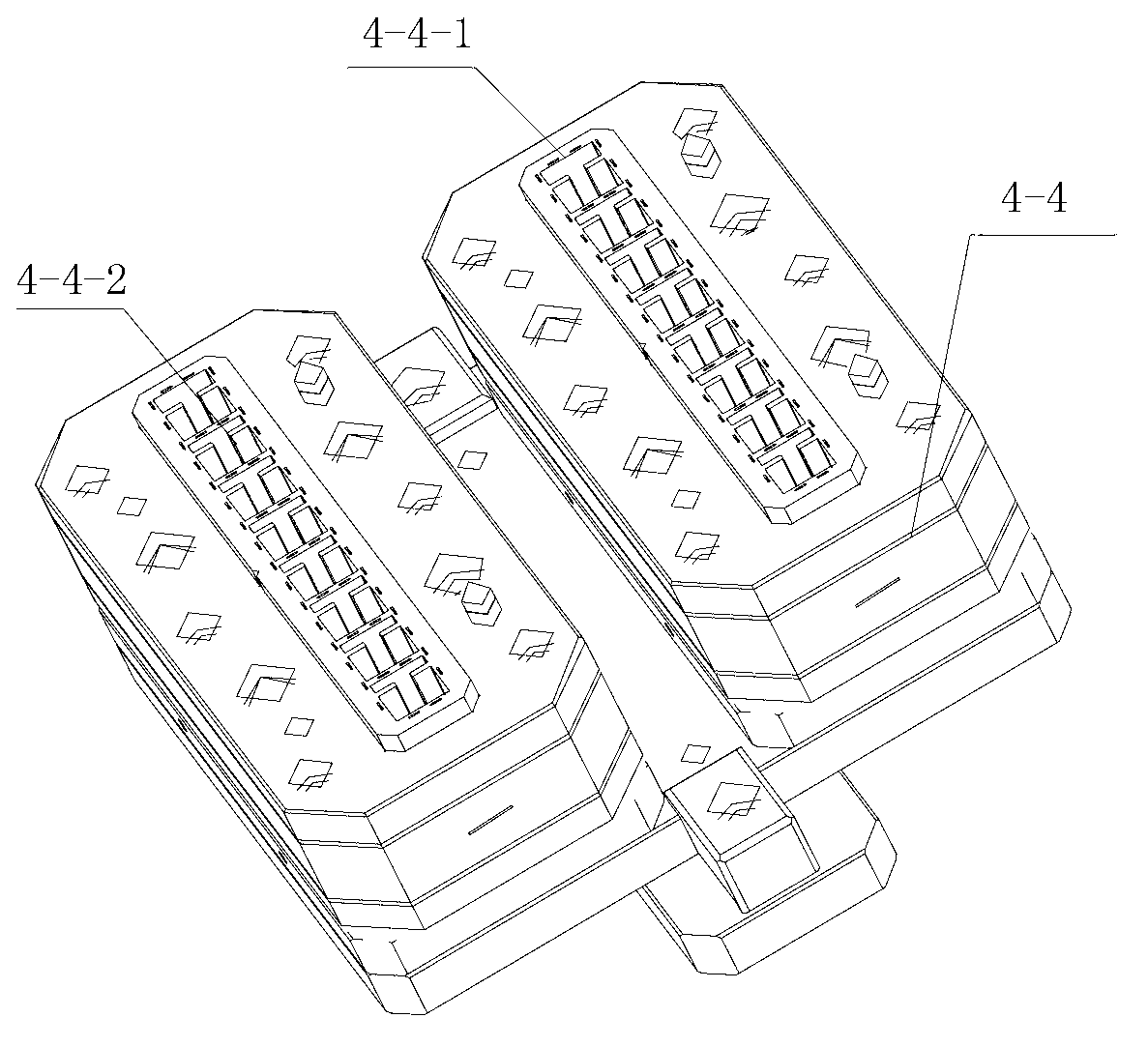

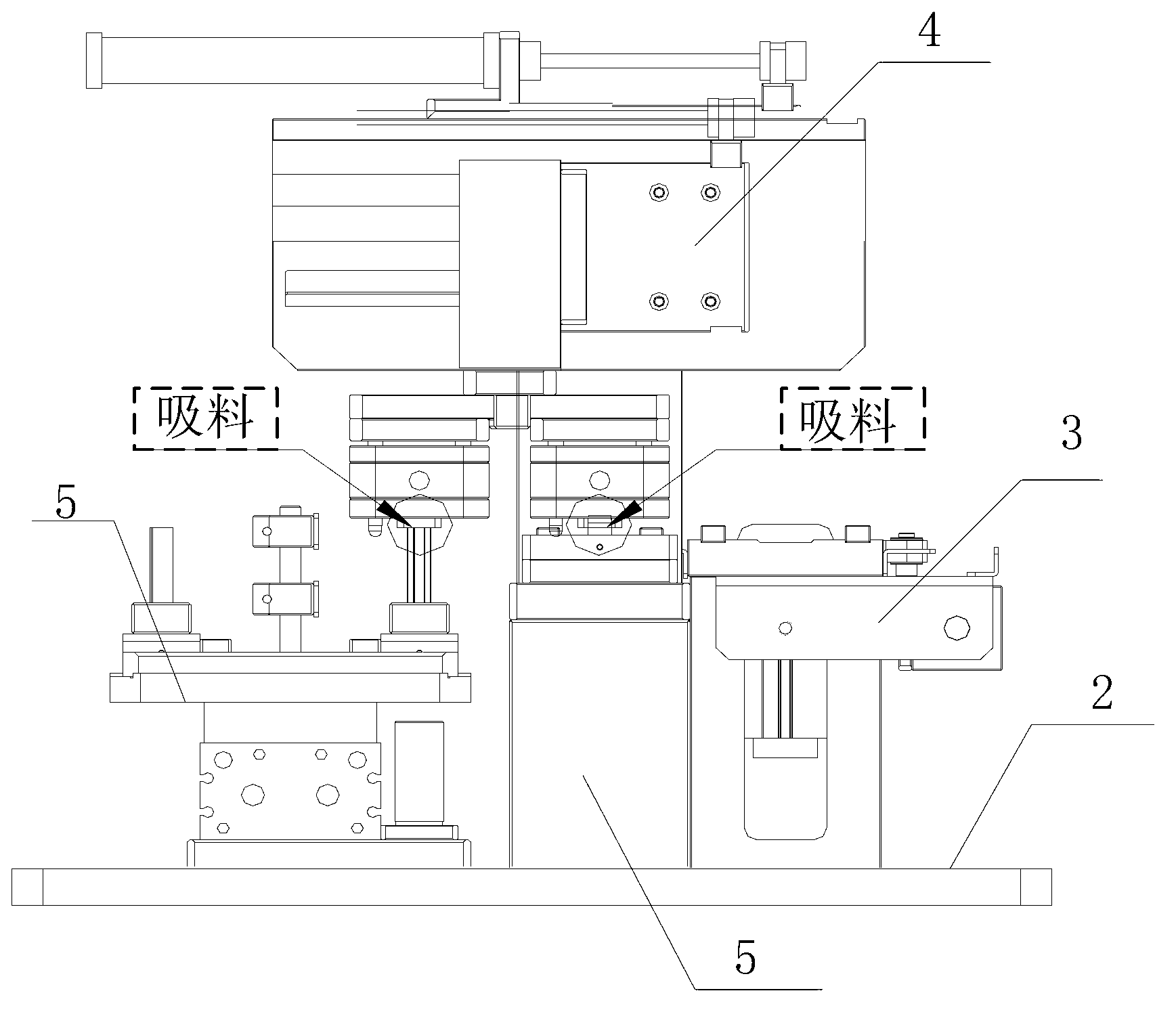

[0016] Such as figure 1 As shown, the electrode sheet automatic feeder includes an electric control cabinet 1, a mechanical base plate 2 is installed above the electric control cabinet 1, an automatic displacement fixture module 3 is installed on the mechanical base plate 2, an electrode sheet module 4 is installed on the left and right, and Electrode sheet feeding module 5, and electrode sheet transfer station 6. The electrode sheet transfer station 6 is located between the automatic displacement fixture module 3 and the electrode sheet feeding module 5 . Among them, the electrode sheet module 4 installed on the left and right includes the electrode sheet adsorption block 4-4, and the electrode sheet adsorption block 4-4 can be placed on the linear slide rail 4-3 through the left and right transplanting cylinder 4-1 and the jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com