Fine adjustment device for capacitive sensor

A technology of capacitive sensors and fine-tuning devices, which is applied in the direction of electric devices, measuring devices, instruments, etc., can solve the problems of thread pitch limitation, low adjustment accuracy, thread backlash, etc., and achieve small fine-tuning, convenient adjustment, and small The effect of fine-tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

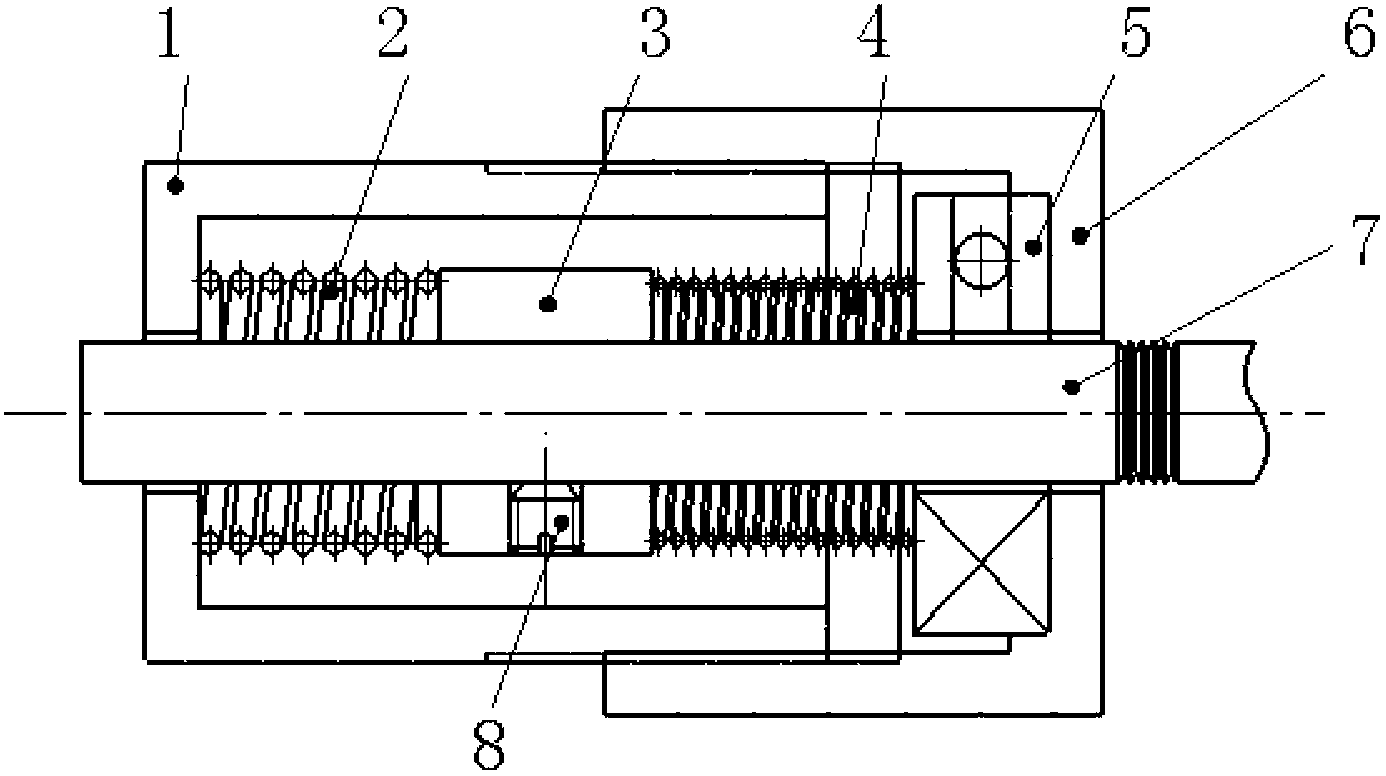

[0023] To make a fine-tuning device, the capacitance probe 7 of the sensor is required to be H=84mm long and 9mm in diameter, and the desired fine-tuning sensitivity is 1μm / rad.

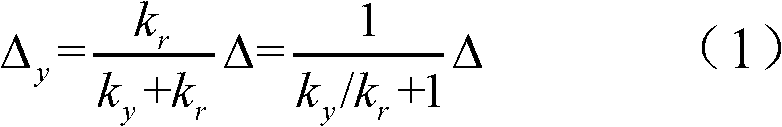

[0024] Step 1. Determine the spring stiffness ratio. Take the pitch of the thread on the fine-tuning sleeve P=2mm, the known fine-tuning sensitivity ρ=10 -3 mm / rad, substituting formula (2) into: k y k r ≈ 318 - - - ( 3 )

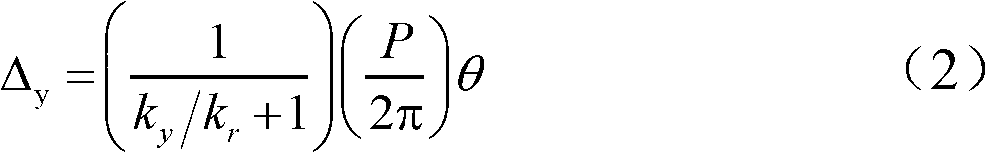

[0025] Step 2. Determine the parameters of the spring. According to the existing public literature and technical data, (Note, here refers to the "Mechanical Design Fundamentals" [M]. Beijing. Higher Education Press, 2006, p308~318, edited and published by Yang Kezhen, Cheng Guangyun, and Li Zhongsheng). The stiffness of each spring is:

[0026] k y = G d y 4 8 D 2 3 n y k r = G d r 4 8 D 2 3 n r - - - ( 4 )

[0027] Where G is the shear modulu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com