Turnover welding and molding production line of H profile steel

A technology of welding forming and H-shaped steel, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increased production cost, low work efficiency, poor safety, etc., to save production cost and improve production efficiency , Fast and accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to clearly illustrate the technical features of the present solution, the present invention will be further described through specific implementations in conjunction with the accompanying drawings.

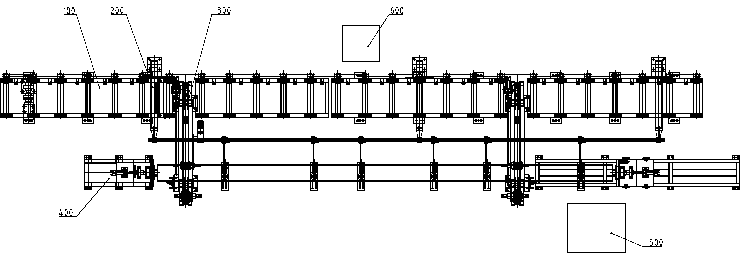

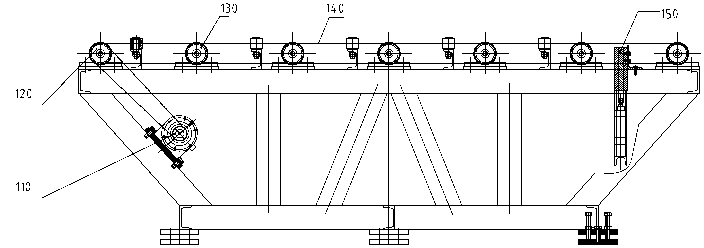

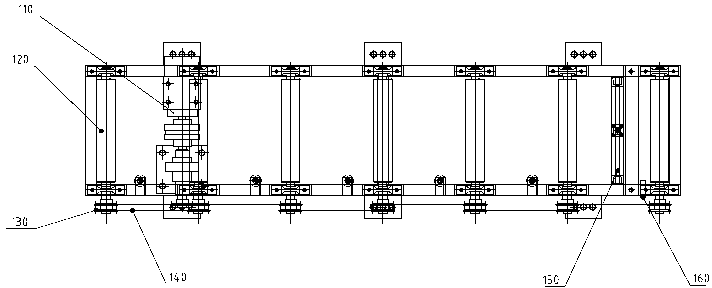

[0038] Such as Figure 1 to Figure 18 As shown, the H-beam turning and welding forming production line includes a longitudinal forehead 100 and a transverse conveying channel 300 in the traveling direction of the H-beam. The longitudinal forehearth 100 and the transverse conveying channel 300 are respectively connected to the hydraulic power unit 600 and the electric control device 500. It includes a connecting plate positioning device 200 and an inverted welding forming device 400. The inverting welding forming device 400 is connected to the hydraulic power device 600 and the electrical control device 500. The longitudinal forehearth 100 is provided with a longitudinal positioning device 150; the transverse conveying material The road is equipped with a lifting devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com