Flight parameter measurement system for small-size bypass aircraft

A technology for measuring systems and flight parameters, which is applied to measuring devices, testing of machine/structural components, instruments, etc. It can solve problems such as errors, difficult flight parameters, unreasonable design of the whole machine structure and control system, etc., to improve accuracy. Sex, avoid the effect of coupling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

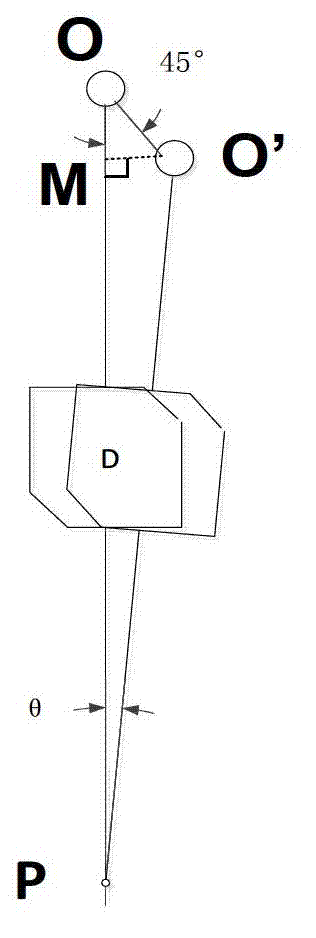

[0019] The invention provides a flight parameter measurement system for a small ducted aircraft, figure 1 It is the schematic diagram of the internal connection of the system. The system includes a test platform seat 1, a linear guide rail 2, a torque sensor 3, a universal joint coupling 4, a small ducted aircraft 6, a workbench 7, a first joint bearing 8, and a hinge 9 , sliding bearing 10, optical shaft support seat 11, first axial limit ring 12, fixed shaft 13, optical axis 14, steel rods 15~17, second joint bearing 18, second axial limit ring 19 and pull The pressure measurement devices 51-55, the tension and pressure measurement devices are composed of tension and pressure sensors connected with rigid shafts on both sides, and the two rigid shafts are coaxial.

[0020] The connection relationship between the various components of the system is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com