Antenna reflective surface phase correction film and reflective surface antenna

A phase correction and reflective surface technology, which is applied in the field of metamaterials, can solve problems such as phase error of the electromagnetic wave exit surface, and achieve the effect of improving the phase error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

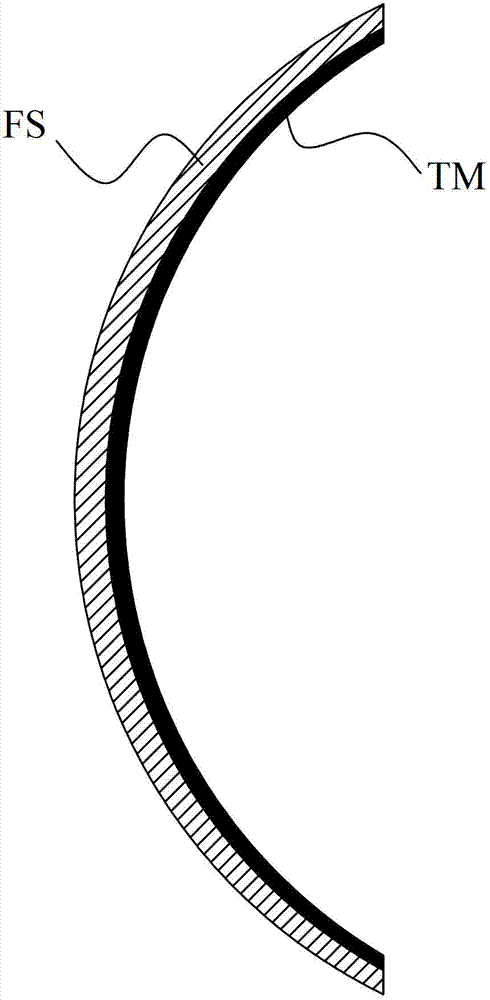

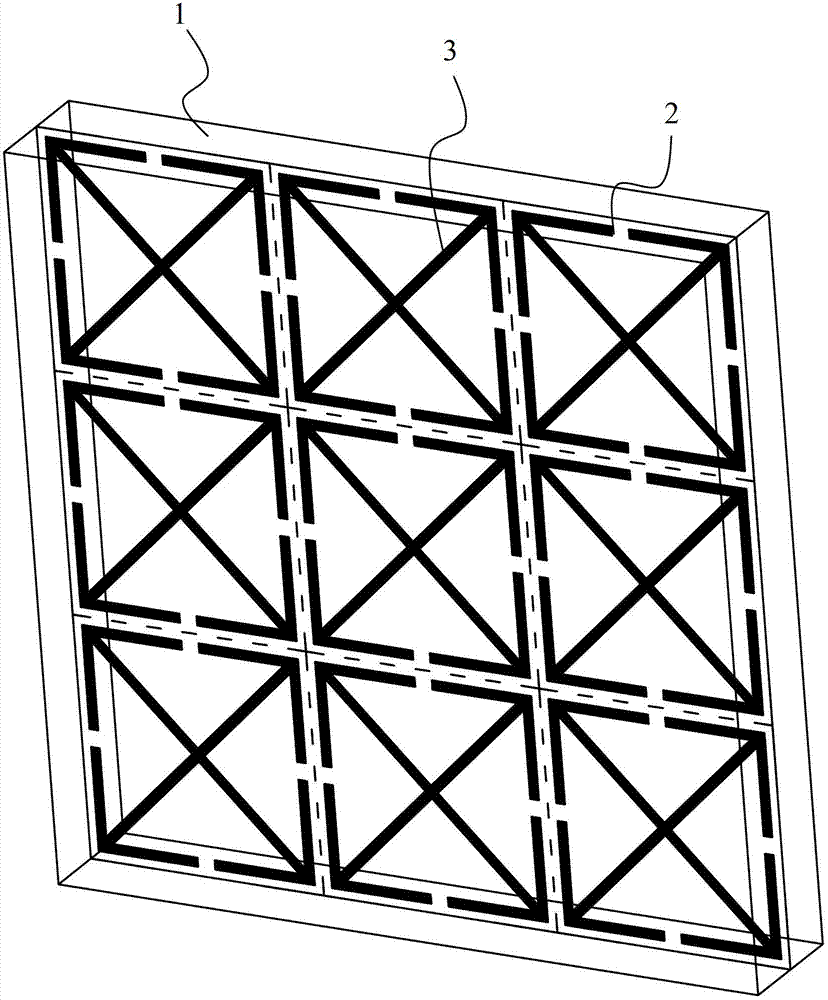

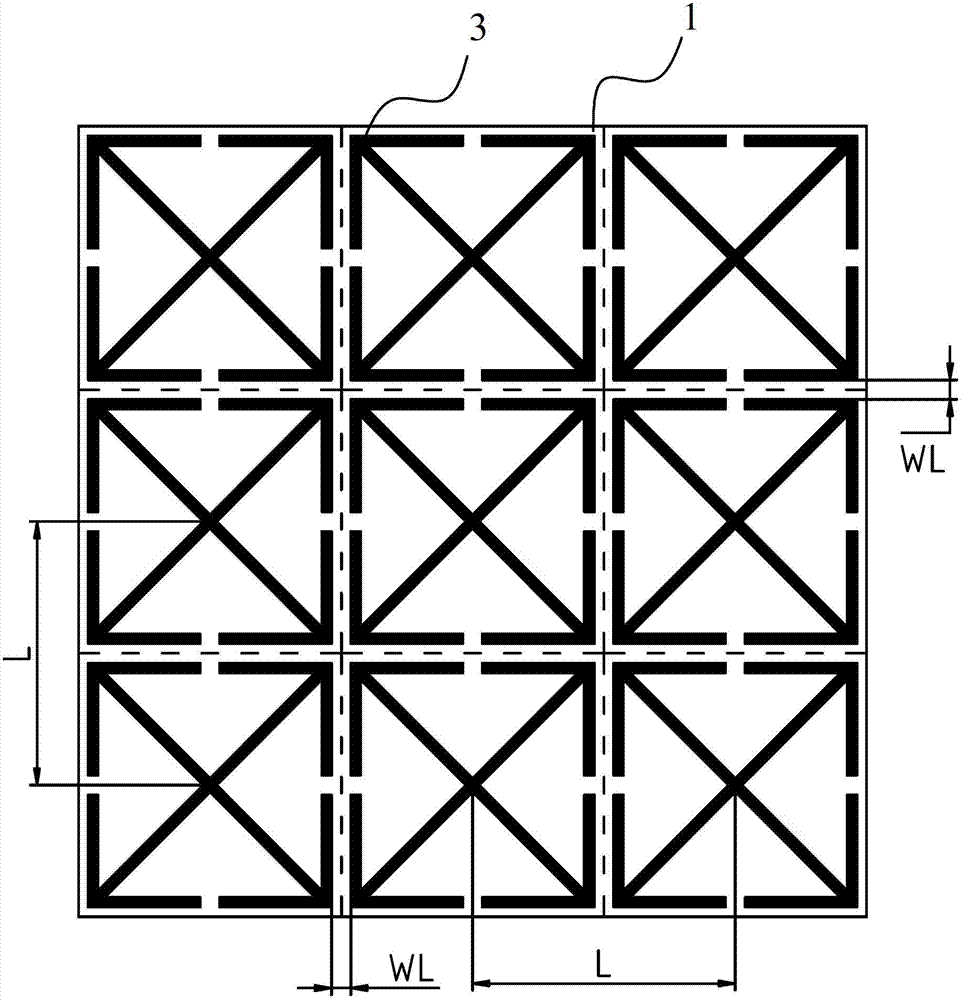

[0040] Such as Figures 1 to 2 As shown, the antenna reflective surface phase correction film TM according to the present invention includes a first substrate 1, a second substrate 2 and a plurality of artificial microstructures 3 arranged between the first substrate 1 and the second substrate 2, the artificial microstructures Structure 3 is a thread made of conductive material, the first substrate 1 and the second substrate 2 are flexible substrates, and the refractive index distribution of the phase correction film TM on the antenna reflective surface is reasonably designed so that electromagnetic waves pass through the antenna reflective surface phase After being reflected by the antenna reflective surface FS of the bit correction film, the outgoing electromagnetic wave has a flat equi-phase surface.

[0041] The flexible substrate of the present invention is the polyimide or polyester film used in the traditional flexible circuit board (FPC). The artificial microstructure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com