Electric rotating slideway for movable camera shooting

A technology of electric rotation and sliding rails, which is applied to the camera body, optics, instruments, etc., can solve the problems of inconvenient carrying, limited shooting site, poor stability and uniform speed, etc., and achieve high-quality shooting pictures and increase the height range , The effect of simple connection relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

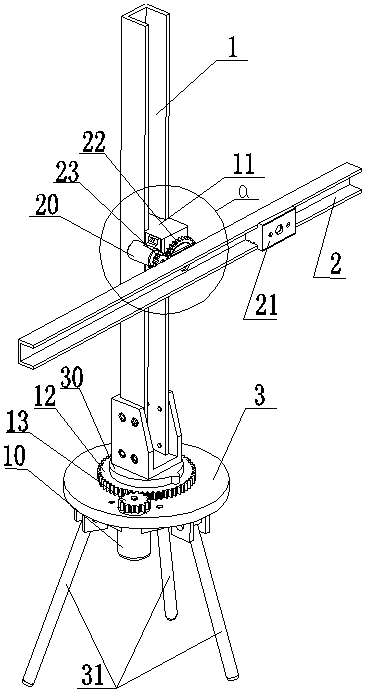

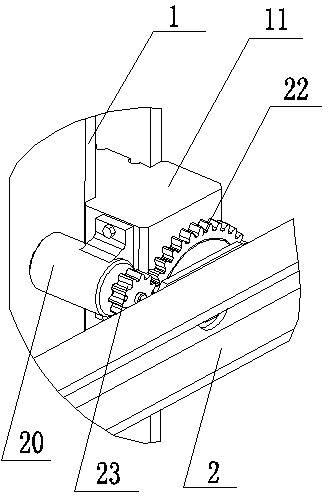

[0024] Example: An electric rotary slide rail device for mobile photography, the support base 3 is provided with a turntable 30, the first slide rail 1 is vertically fixed on the turntable 30, the first motor 10 is fixed on the support base 3, and the first transmission mechanism is connected Between the first motor 10 and the turntable 30, the first slider seat 11 is provided on the first slide rail 1, and the first slider seat 11 can slide along the first slide rail 1; the first motor 10 works, and passes through the first slide rail 1 A transmission mechanism drives the turntable 30 to rotate so that the first slide rail 1 rotates in the horizontal direction, realizing horizontal and uniform rotation shooting at any height within the length range of the first slide rail 1 .

[0025] The first transmission mechanism can adopt any transmission mechanism in the prior art that can transmit the torque converted by the first motor 10 to the turntable 30 to rotate the turntable 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com