Device for avoiding arching of materials in stock bin by using sliding frame

A carriage and silo technology, applied in the field of silo arch breaking devices, can solve the problems of irregular maintenance, large wear and tear of carriage and guide rail, and large friction, so as to avoid the entry of materials and dust, driving force and power The effect of reducing power consumption and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

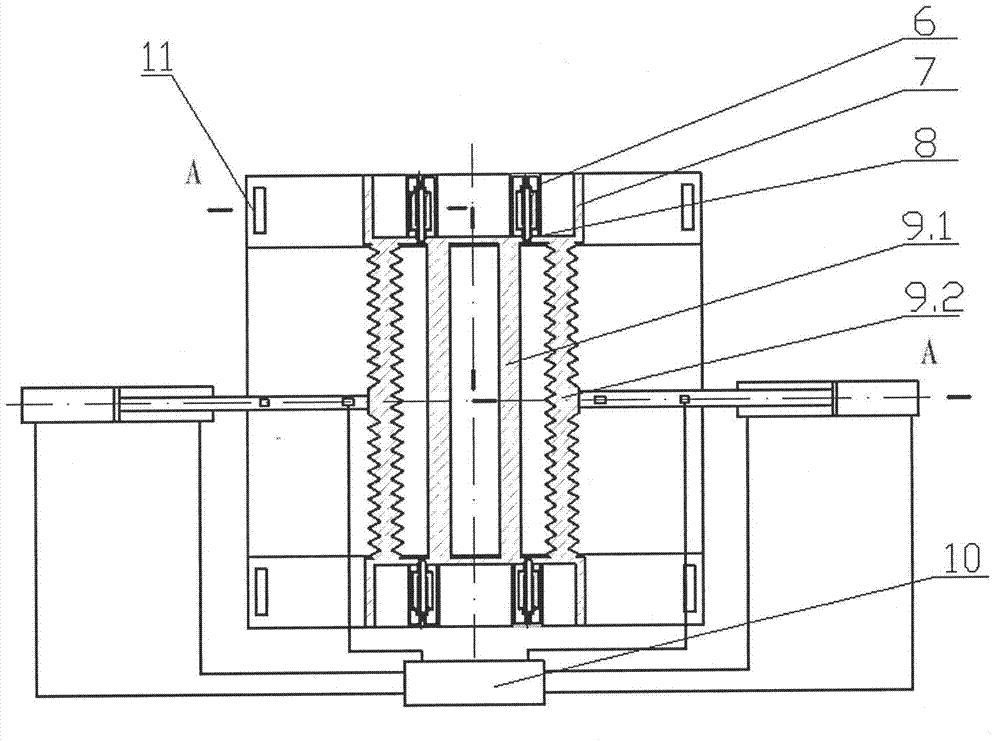

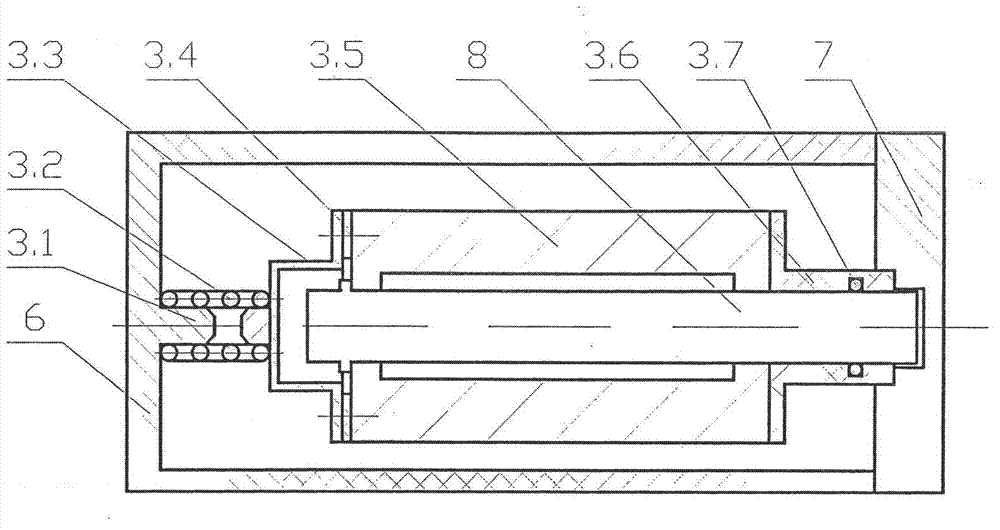

[0017] As shown in the figure, the arch breaking device of the silo carriage of the present invention includes a guide rail 1, a carriage, a power system 10 and a silo body 4, the guide rail 1 is arranged on both sides of the bottom of the silo body 4, and the The carriage is composed of a carriage body 7 and a carriage rod 9, and is characterized in that: the guide rail 1 is provided with a roller cover 6 and a roller 3, and the roller cover 6 and the roller 3 are connected with the carriage at the same time, and the roller 3 Placed in the roller cover 6, the carriage rod 9 includes inner and outer carriage rods and is distributed symmetrically along the center of the carriage, the inner carriage rod 9.1 is rectangular, and the outer carriage rod 9.2 is sawtooth . The four surfaces of the roller cover 6 itself, the lower end surface of the cover pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com