Special drilling machine for processing porous gear

A technology of gears and drilling machines, applied in boring/drilling, metal processing equipment, drilling/drilling equipment, etc., can solve the problems of inconvenient positioning of gears, frequent operations, low production efficiency, etc. The effect of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

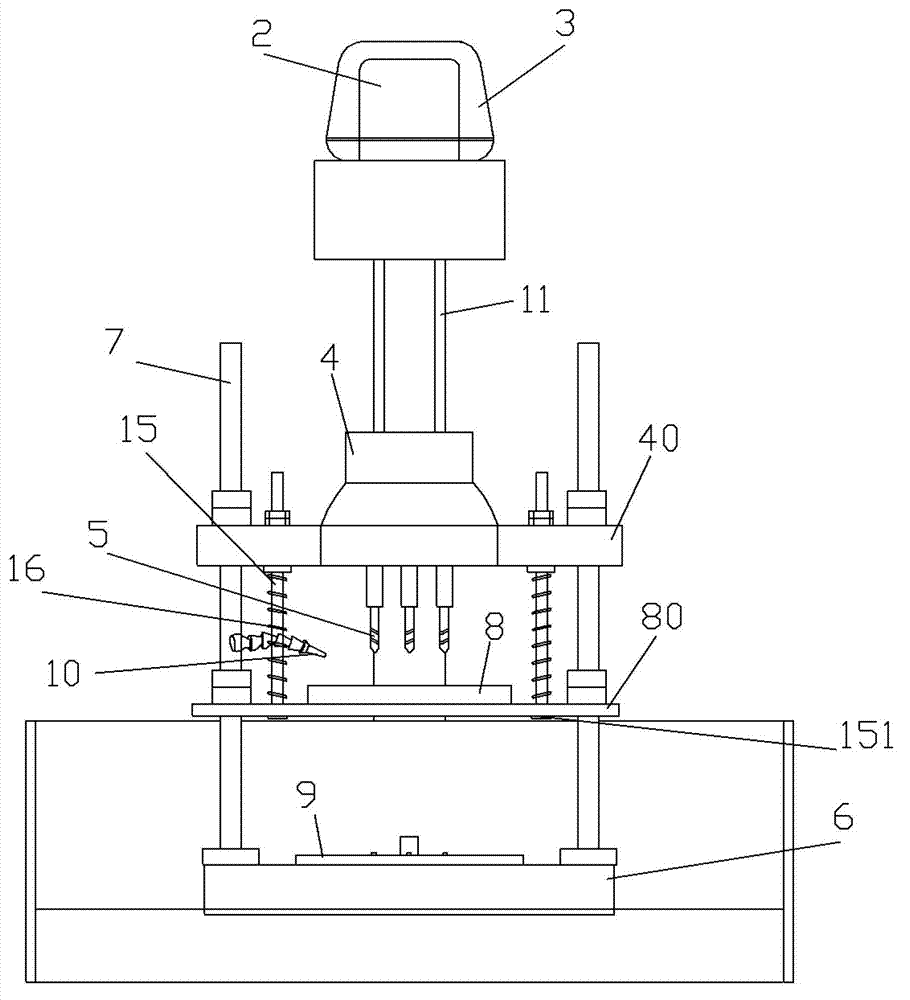

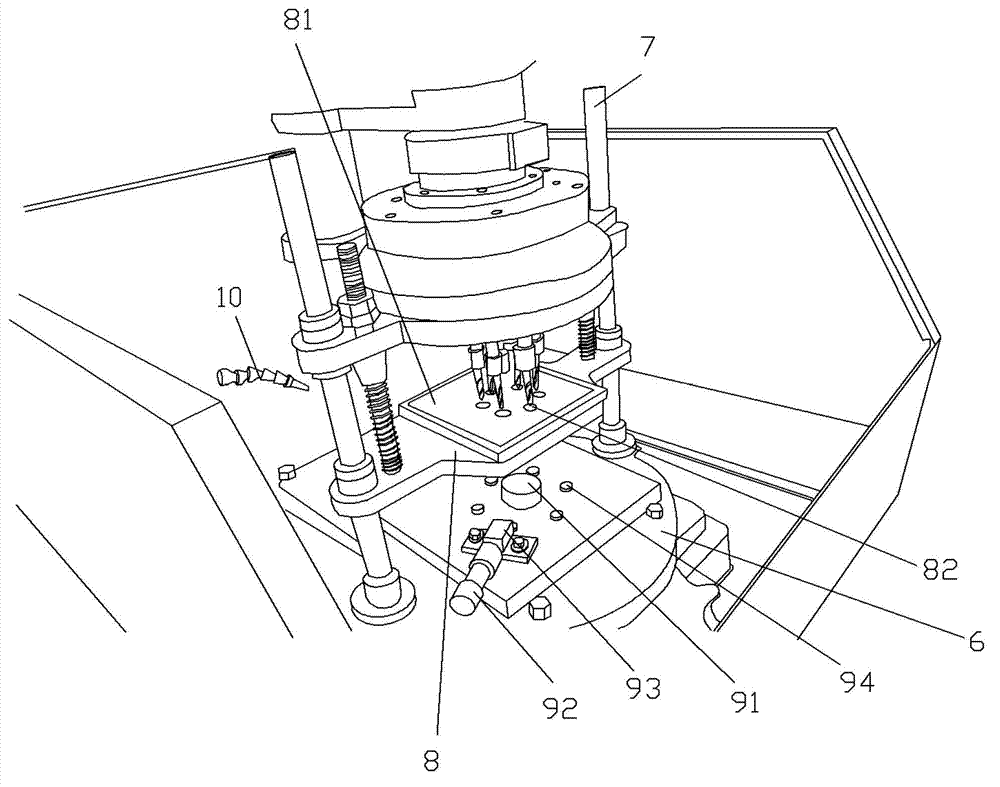

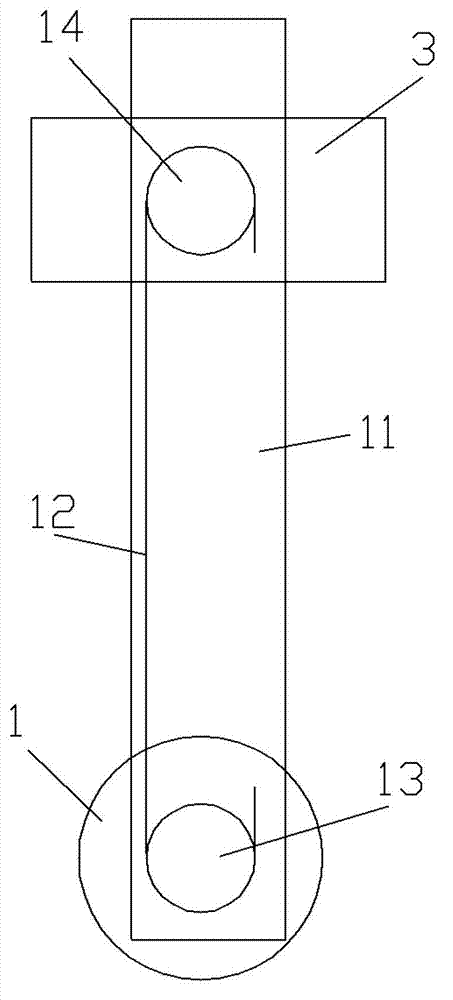

[0020] Example: see Figures 1 to 4 As shown, the special drilling machine for porous gear processing includes a lifting motor 1 and a drilling motor 2. The drilling motor 2 is fixed on the lifting frame 3. The rotating shaft of the drilling motor 2 is fixed on the driving gear 41 of the planetary gearbox 4. There are several driven gears 42 in an annular array on the periphery of the gear 41, the driven gears 42 mesh with the driving gear 41, and the drill bit 5 is fixed on the rotating shaft of the driven gear 41;

[0021] A column 7 is fixed on the workbench 6, a gear box insert plate 40 is formed or fixed on the planetary gearbox 4, the gear box insert plate 40 is inserted on the column 7, and a cooling insert plate 80 is formed on the cooling platen 8 , the cooling sleeve plate 80 is inserted on the column 7;

[0022] The middle part of the cooling platen 8 is formed with a liquid tank 81, and the bottom of the liquid tank 81 is formed with a through hole 82, and the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com