Non-contact dip angle measuring device and method

A non-contact, measuring device technology, applied in the field of measurement, can solve problems such as inconvenient operation, high requirements for measurement angle of view, and the need for contact between the measuring instrument and the measured object, so as to improve measurement efficiency and accuracy and reduce labor intensity , the effect of accurate inclination measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

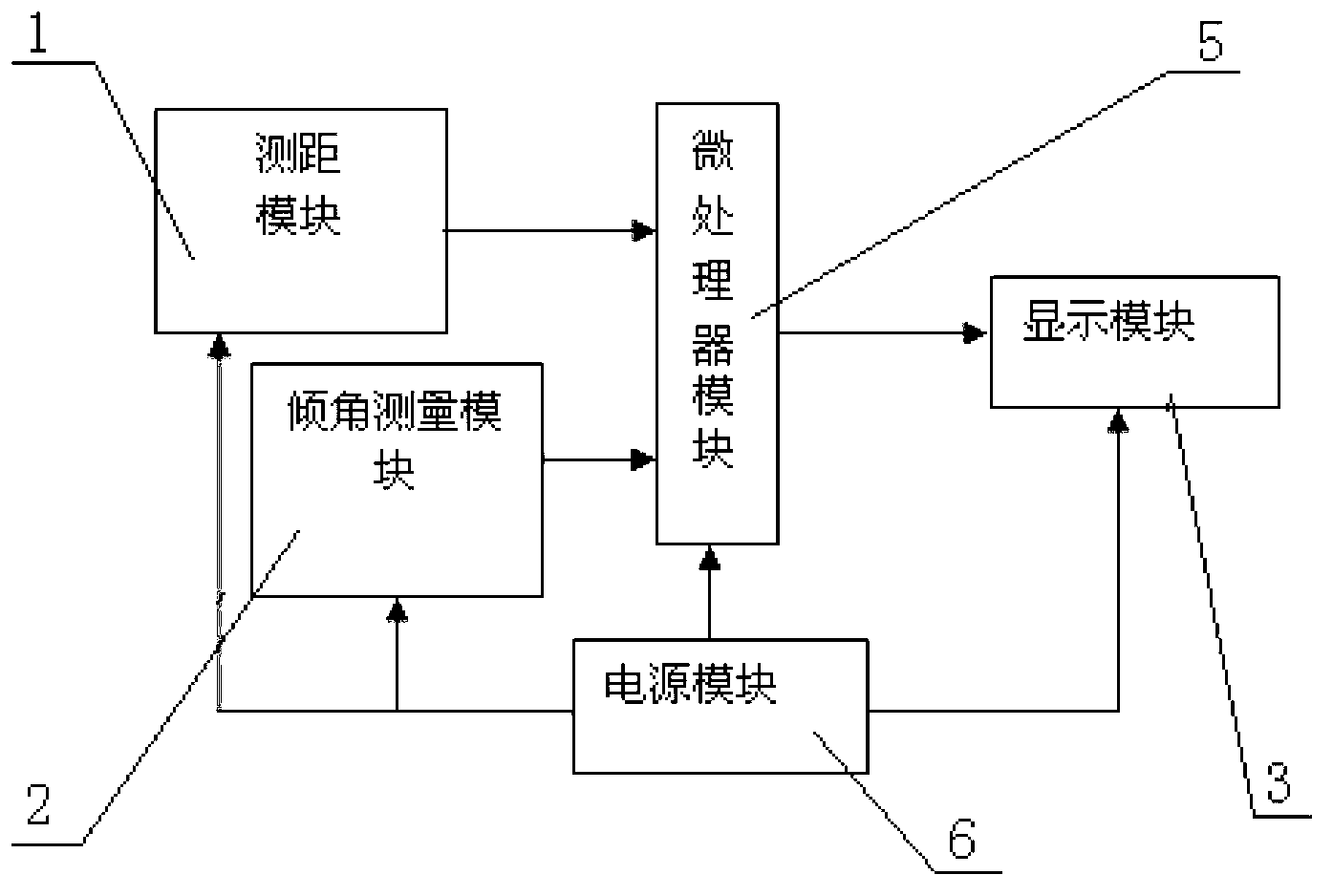

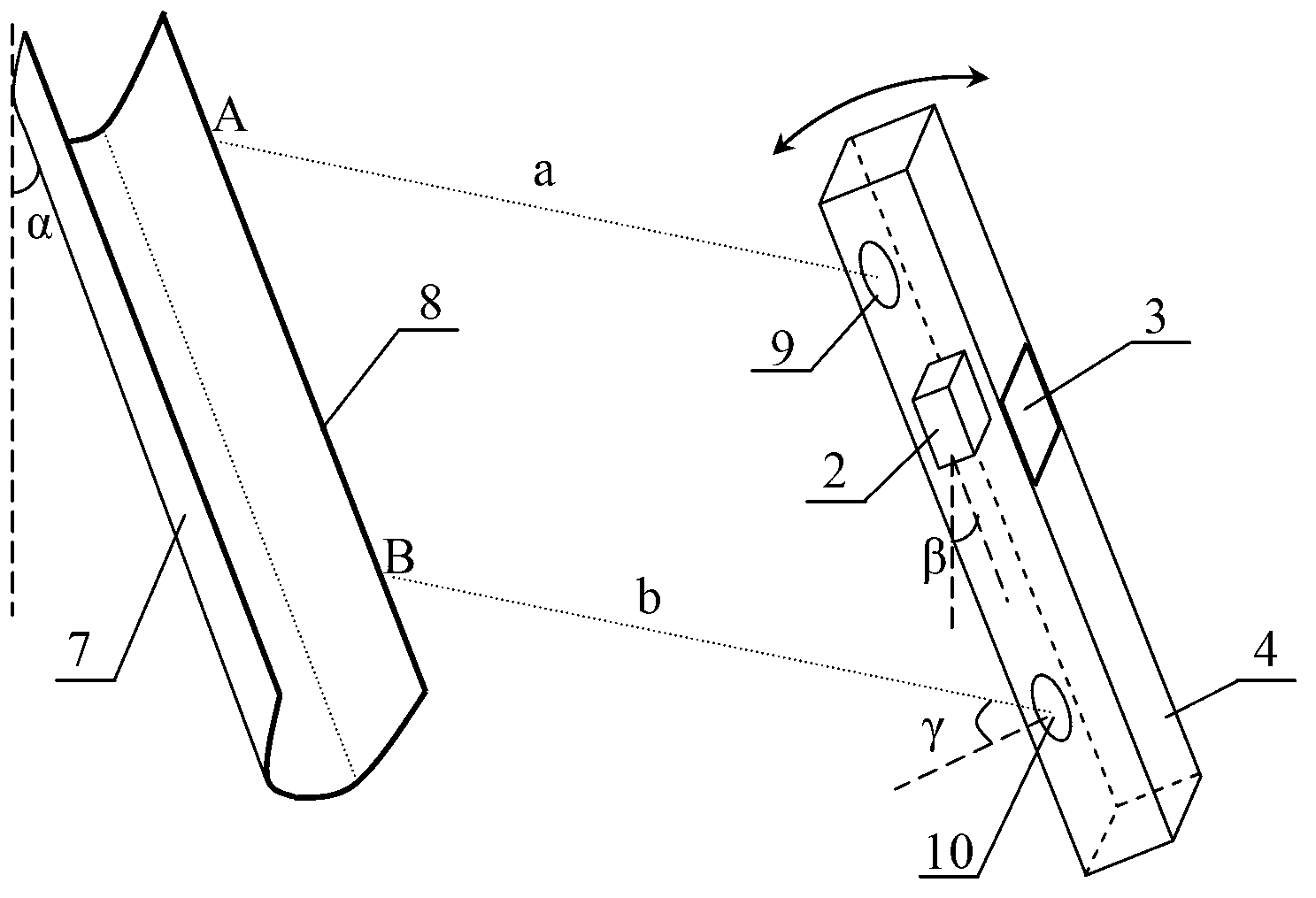

[0017] see figure 1 and figure 2 , a non-contact inclination measuring device provided by an embodiment of the present invention includes a body 4 on which a distance measuring module 1, an inclination measuring module 2, a microprocessor module 5, a display module 3, and a power supply module 6 are arranged. , the ranging module 1, the inclination measuring module 2 and the display module 3 are respectively connected with the microprocessor module 5, the power supply module 6 is connected with other modules, the ranging module 1 is installed on one side of the body 4, and the ranging module 1 is installed. One side serves as a measurement reference surface at the same time, and the other side of the main body 4 is installed with a display module 3 . The ranging module 1 is composed of two independent laser ranging units 9 and 10 with the same accuracy. The laser ranging unit 9 and the laser ranging unit 10 are separated by a certain distance on the body 4, and the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com