Wing skeleton and manual transmission device of bird-imitating manual flapping-wing flight

A transmission device and manpower technology, applied in the field of human-powered bionic flapping-wing aircraft, can solve the problems of heavy weight, large distance, large volume, etc., and achieve the effects of reducing fatigue, natural angle, and reliable force method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] The device is different in the size and spring coefficient of each part according to the difference of the height and weight of the human body. In this specific embodiment, a human body with a height of 170-180 cm and a weight of about 70 kg is taken as an example to determine the size and spring coefficient of each part. spring rate.

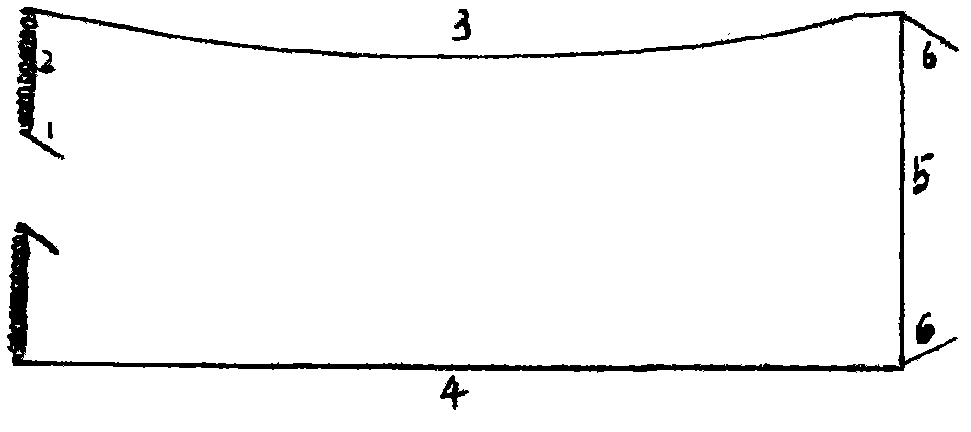

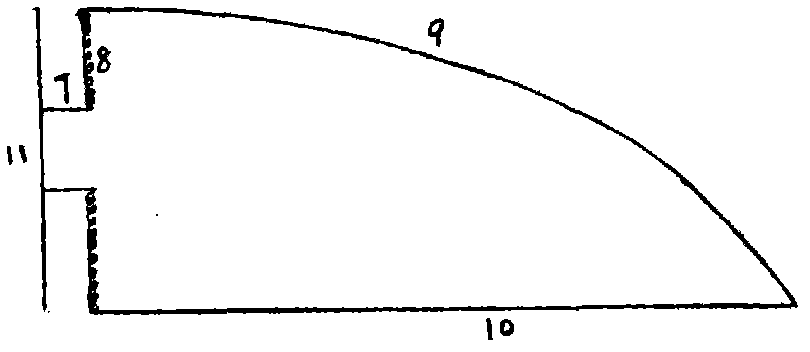

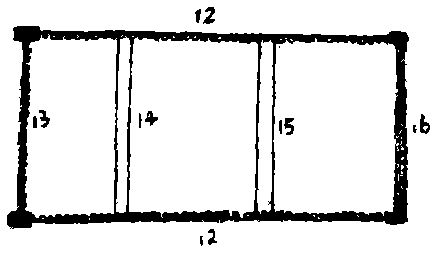

[0028] Inner wing torsion spring (2) long 25cm, wire diameter 9.9mm, reed pipe diameter 35mm, do not stay space between the pipe turns. Inner wing torsion spring inner arm (1) long 20mm, inner wing torsion spring outer arm (4) length is 150cm, inner wing torsion spring outer arm (3) long 160cm and determines its radian according to this length. Inner wing torsion spring outer arm vertical bar (11) length is 70cm.

[0029] Outer wing torsion spring (8) is long 25cm, and wire diameter 3mm, reed pipe diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com