Comprehensive reliability evaluation method based on multi-test information

A comprehensive evaluation and reliability technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of difficult to obtain the life of the environmental factor and difficult to carry out reliability evaluation, and simplify the determination of the environmental factor. process, easy to apply effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] It is known that a sample of an electromechanical product has undergone a 1000-hour life test and a 200-hour environmental test. In the absence of other test data, it is hoped to evaluate its mean time between failures. Since no corresponding reliability test has been carried out on the product, and the sample is only one product, it is difficult to evaluate it by conventional methods, so the method described in the present invention is used for evaluation.

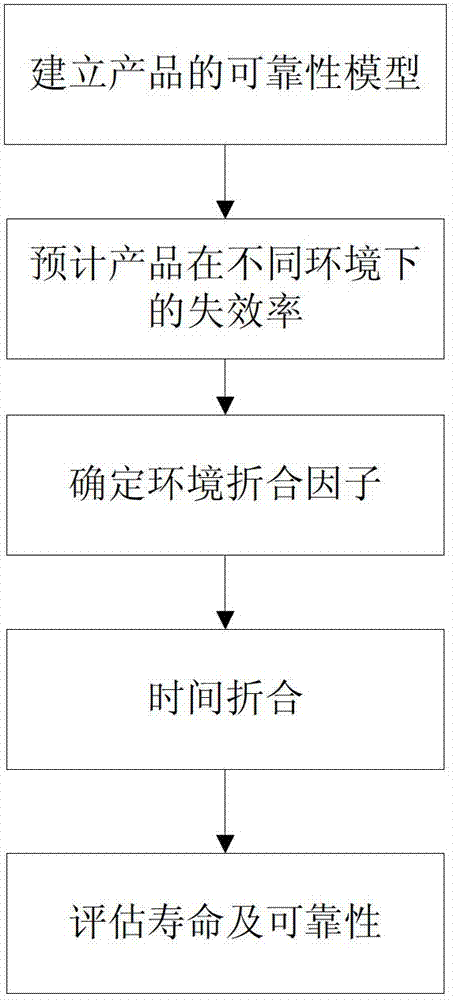

[0063] Step 1. Establish a product reliability model

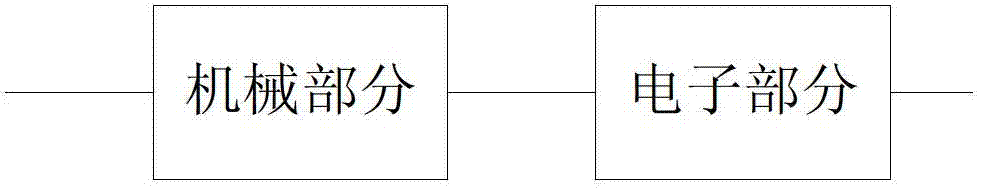

[0064] Analyze the structure and function of the product, and establish a reliability block diagram of the product based on the principle, function and functional process of the product. After the analysis of the product, the product is composed of two parts, namely the mechanical part and the electronic part, and the relationship between the reliability of these two parts obeys the series model. Its reliability block diagram is as follows Figure 4 shown.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com