Method for fast predicting side wall leakage of underground diaphragm wall using infrared thermal fields

A technology of underground diaphragm wall and thermal field, which is applied in the test of foundation structure, construction, foundation structure engineering, etc., and can solve the problems of underground diaphragm wall leakage and failure to take into account

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

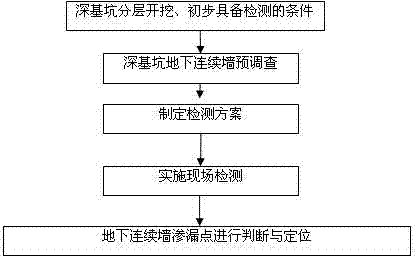

Method used

Image

Examples

Embodiment 1

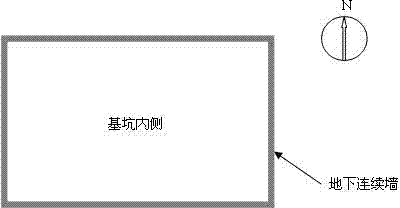

[0026] Embodiment 1: Taking the leakage point test of the underground diaphragm wall of a foundation pit in a certain area as an example, the specific application is carried out according to the following steps:

[0027] Project overview: On-site geological survey shows that within the influence range of the underground diaphragm wall of the target foundation pit, the stratum is divided into 3 layers, and the depth of the foundation pit is 9m. 1 A layer of silty clay with a thickness of 1.5m;② 3 A layer of sandy silt with a thickness of 3.6m; ③ a layer of muddy silty clay with a thickness of 2.4m; layer ④ is a layer of medium-sand and other soils with better stress.

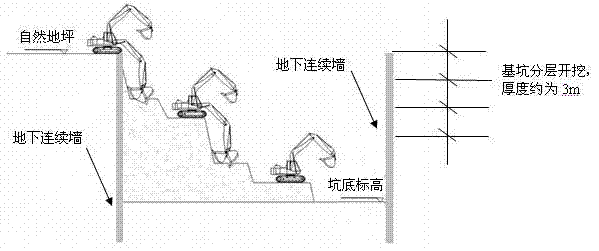

[0028] Step 1: The deep foundation pit is excavated in layers. According to the requirements of the design drawings and construction specifications, after the water is pumped down to 0.5 m below the bottom of the foundation pit, the deep foundation pit can be excavated in layers, with a layer thickness of 3m.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com