Substrate conveying apparatus and method

A technology of conveying device and substrate, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve problems such as interference between worktable and guide rail, inability to install multiple electronic components, and wrong assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be described below with reference to the drawings.

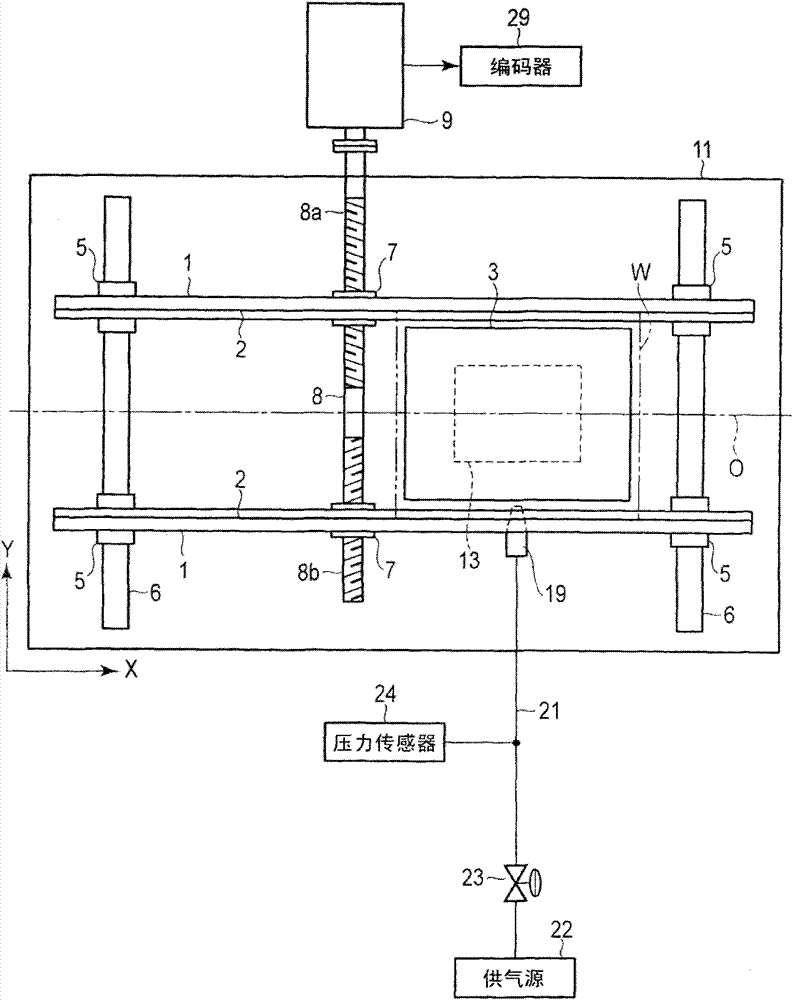

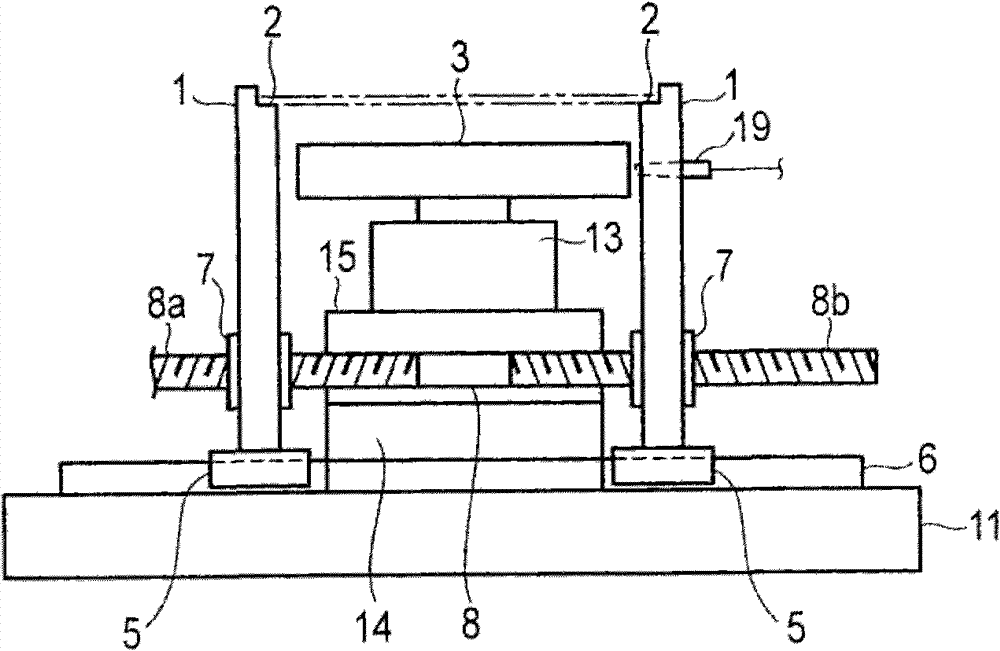

[0046] Figure 1-Figure 6 The first embodiment of the present invention is shown. figure 1 The conveying device shown has a rectangular base plate 11 . A pair of guide rails 1 spaced apart at a predetermined interval are provided in the width direction of the upper surface of the substrate 11 . Let the departure direction of a pair of guide rails 1 be figure 1 The Y direction in the X and Y directions shown. At the upper end of a pair of guide rails 1, such as figure 2 As shown, there are formed step portions 2 on which both end portions in the width direction of the substrate W on which electronic components P such as IC chips are mounted are engaged and supported.

[0047] The substrate W placed on both ends in the width direction engaged with the step portion 2 is conveyed at intervals of a predetermined distance along the guide rail 1 by a chuck mechanism (not shown)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com