Gas spring automatic aerator

An automatic inflator and gas spring technology, applied in mechanical equipment, container filling methods, gas/liquid distribution and storage, etc., can solve the problems of slow inflation speed, low degree of automation, and low work efficiency, so as to improve work efficiency, The effect of high degree of automation and fast inflation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

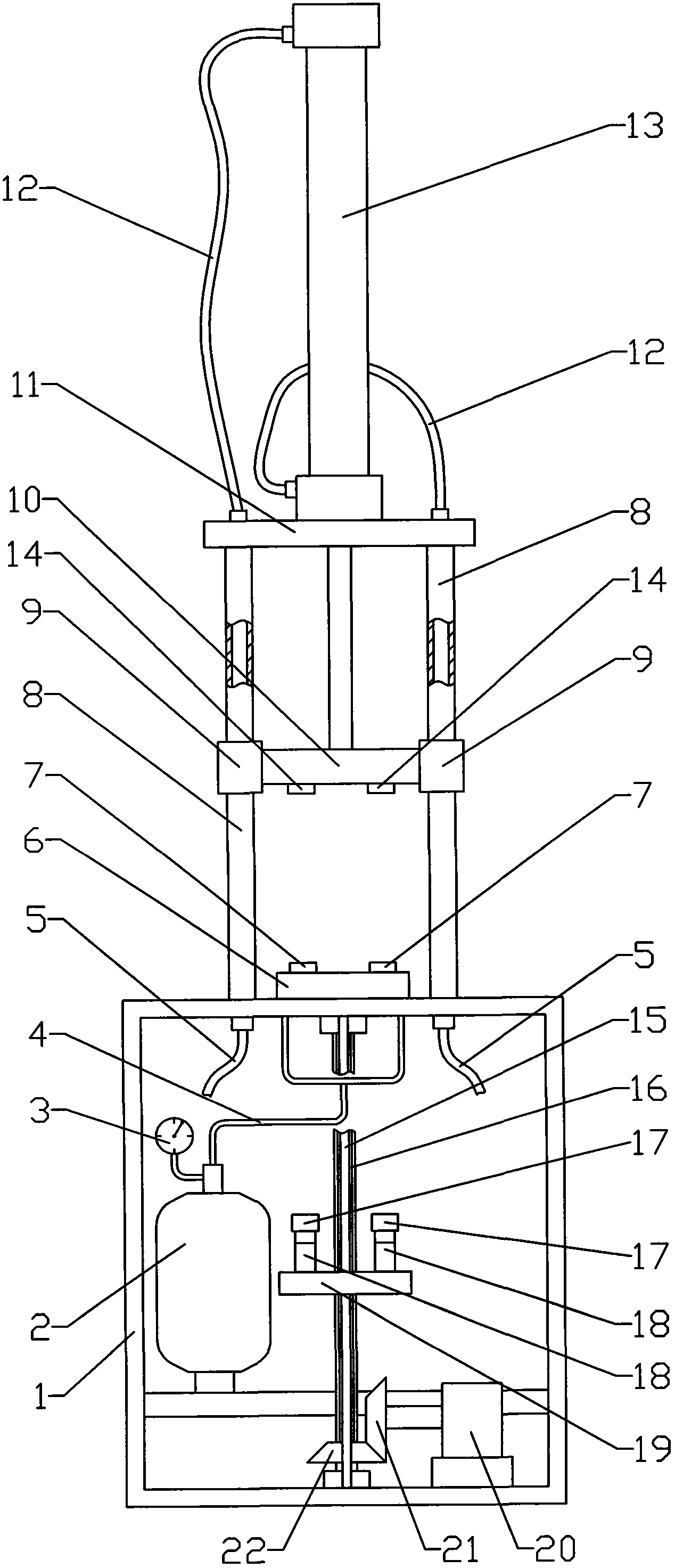

[0023] Embodiment: As shown in the accompanying drawings, the gas spring automatic inflator includes a frame 1, two pillars 8 are arranged on the frame 1, an inflation mold 6 is arranged between the two pillars 8, and the other end of the pillar 8 is provided with A power unit, a pressing plate 10 is arranged between the power unit and the inflatable mold 6, and the pressing plate 10 is connected with a power unit that can drive it to reciprocate along the axial direction of the pillar 8, and a sliding sleeve 9 is set on the supporting pillar 8, and the pressing plate 10 and the sliding sleeve 9 Fixedly connected, the other side of the inflatable mold 6 is provided with a pressure sensor 18 that can reciprocate along the axial direction of the pillar 8 .

[0024] Pillar 8 is vertically arranged, and pillar 8 is positioned at the top of frame 1, and one end of pillar 8 is fixedly connected with frame 1, and the other end of pillar 8 is fixedly connected with support plate 11, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com