Button sewing method and sewing machine for sewing buttons

A button sewing machine and button sewing technology, applied to sewing machine components, sewing machine thread cutting mechanism, sewing equipment, etc., can solve the problem of insufficient improvement of button sewing workability and work efficiency, many troubles, and many troubles. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

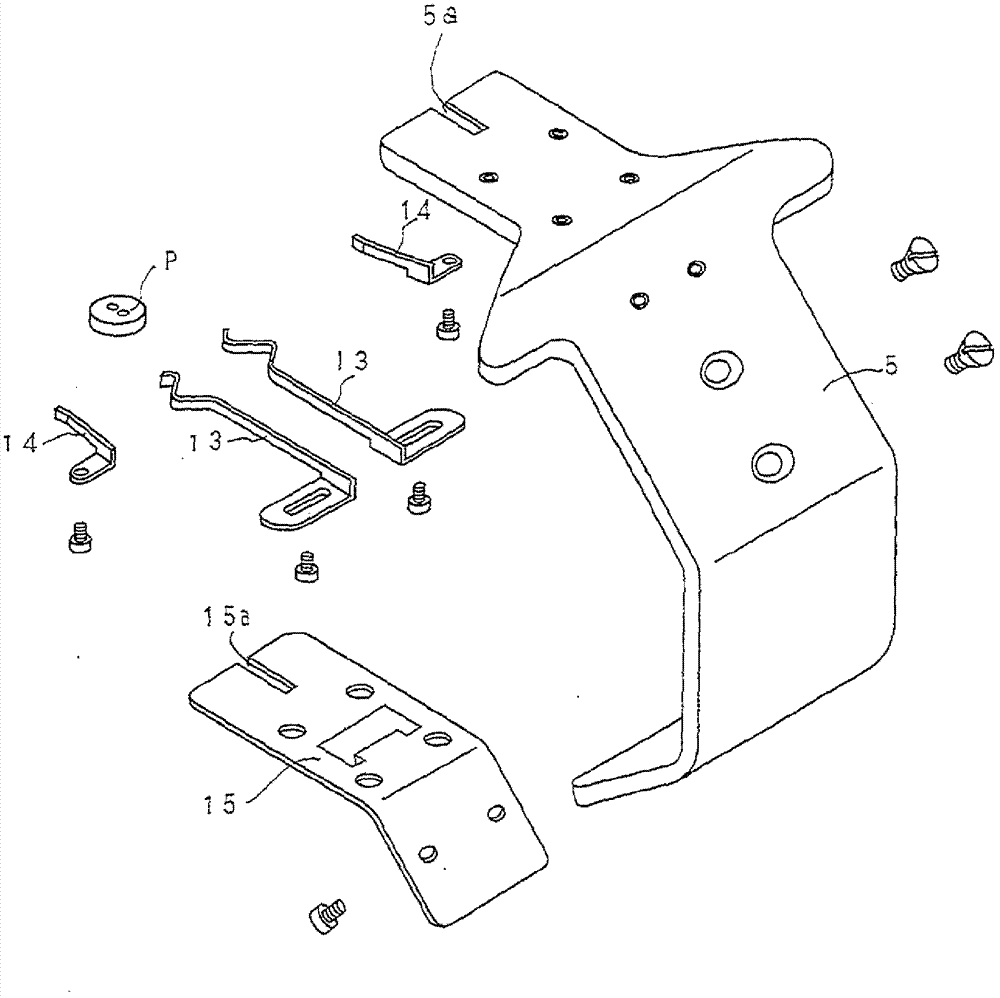

[0055] figure 1 It is an overall schematic perspective view of the button sewing machine of the present invention. Figure 2 to Figure 5 It is a perspective view showing the structure of each main part of the button sewing machine of the present invention.

[0056] like figure 1 As shown, the button sewing machine 1 has: the needle 3 that moves up and down at a certain position through the lifting drive mechanism arranged in the sewing machine arm 2; the outer button support 4 that holds the outer button B; holds the lining button P The buckle support body 5; the loading plate 6 that can support the buckle support body 5; the suture support body (refer to image 3 ) 7; thread cutting tool 50 (refer to image 3 ); winding sewing switching mechanism 8; and fabric pressing plate 9.

[0057] The above-mentioned buckle support body 5 is fixed to the front end po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com