Garlic Combine Harvester

A combined harvester and garlic technology, applied in the field of harvesters, can solve the problems of inability to meet the use requirements, time-consuming and laborious, inability to clean out the garlic at one time, etc., and achieves the level of automation, saving time and effort, preventing sun exposure, and having a high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

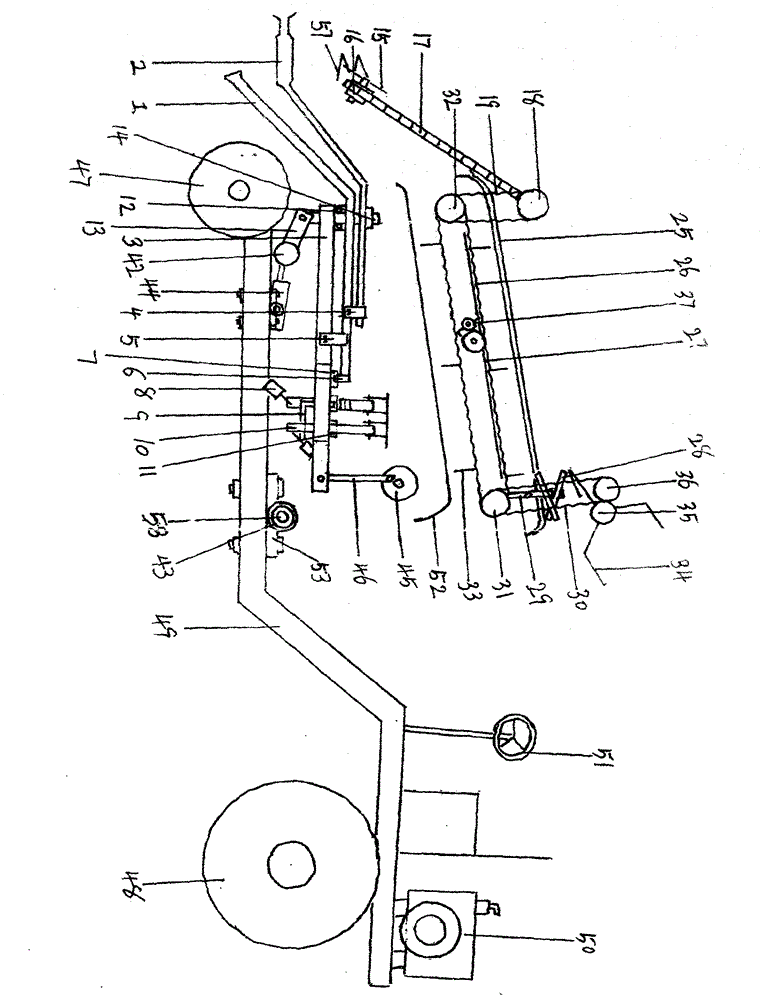

[0017] Accompanying drawing is a kind of specific embodiment of the present invention.

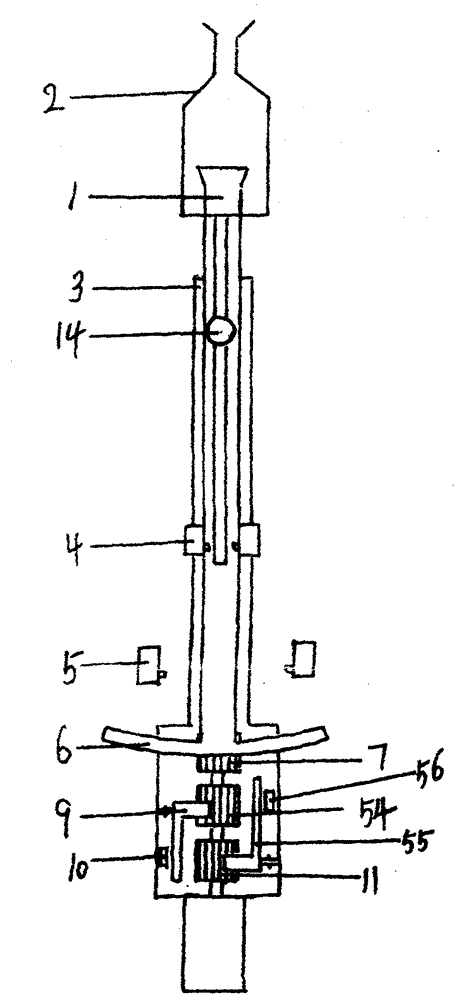

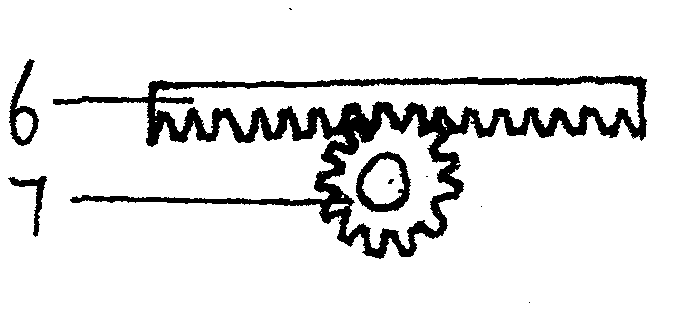

[0018] The garlic combine harvester of the present invention comprises a garlic shoveling system, a garlic pulling system, a conveying and shearing system, a lifting system, and a walking system arranged on the vehicle frame; Knife 1 and sensor 2 are located above the main shovel arm 3, the middle part is positioned by the positioning shaft 14 and the front end of the main shovel arm 3, the lower end of the positioning shaft 14 is positioned with the bracket 13 fixed on the front frame 42, and the rear end of the main shovel arm 3 is used for positioning. The connecting rod 46 is connected with the eccentric wheel 45 on the frame, and the main shovel arm 3 is also equipped with a control and adjustment device for the auxiliary shovel 1; The garlic pulling sprockets at both ends are positioned at the two ends of the garlic pulling frame 24, and the garlic pulling frame 24 is fixed on the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com