Welding-free assembled type framework and bolt latch

An assembly-type, welding-free technology, which is applied in the field of special bolt locks and welding-free assembled steel skeletons, can solve the problems of increasing project management difficulty and construction costs, troublesome construction, and high construction quality, so as to improve construction safety, The effect of shortening the construction time and increasing the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Embodiment 1——Adjustable skeleton of welding-free assembly type:

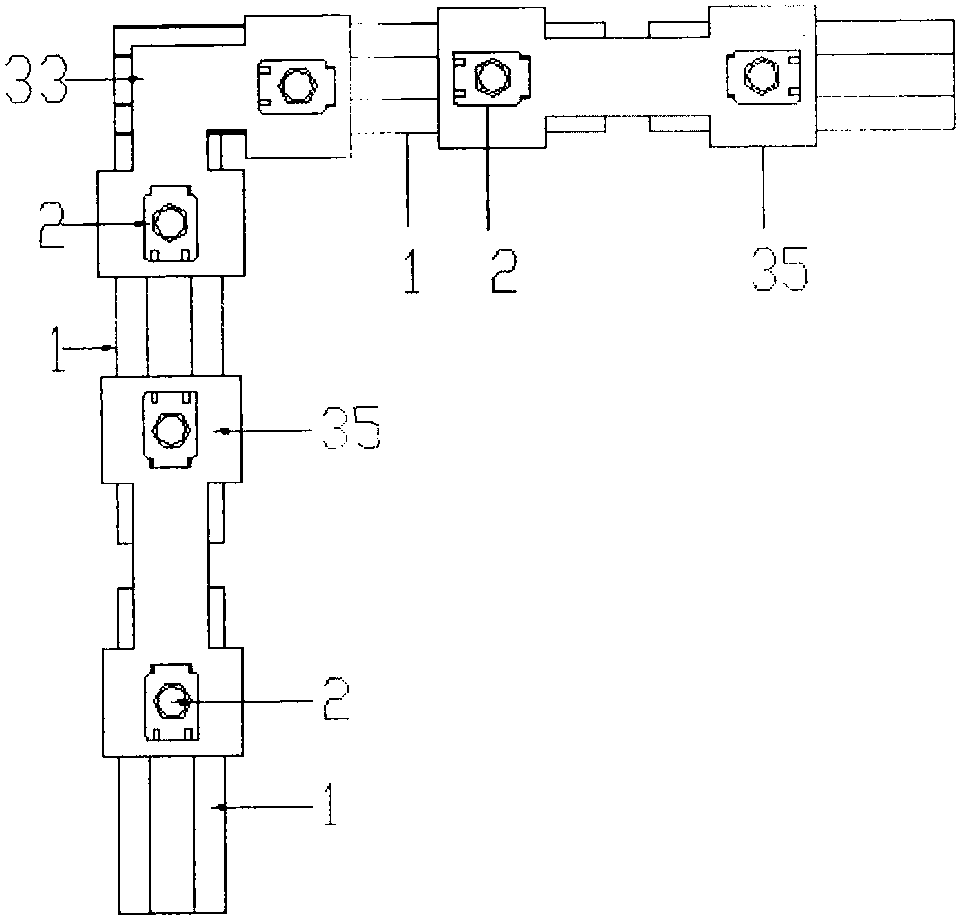

[0072] The skeleton provided by the present invention is installed on the main structure of the building including walls, beams, etc., the skeleton of this embodiment 1 includes a keel 1 provided with a channel groove 11, a main body fixing part, a keel connector, a slider and a dry hanging part 10, The main body fixing member comprises an L-shaped fixing adjusting member 5 and a Type of fixed connector 8. The keel 1 is connected to the fixed connecting piece 8 through a bolt lock 2 . The structure and connection relationship between the fixed adjusting part 5 and the fixed connecting part 8 are as follows: figure 1 As shown, the two sides of the fixed connector 8 are respectively connected with an L-shaped fixed adjustment member 5. In view of the different requirements for the fixed distance of decorative panels such as stone and main structures of buildings such as walls and beams in actual use, th...

Embodiment 2

[0085] Embodiment 2——welding-free assembly skeleton:

[0086] Embodiment 2 provides another kind of embodiment of the present invention, and its structure is as Figure 28 , Figure 29 As shown, the skeleton in Embodiment 2 includes a keel 1, a main body fixing part 6, a keel connector and a slider, the keel 1 is connected with the main body fixing part 6, and the main body fixing part 6 is fixed on the main structure such as a wall or other buildings , the keels 1 are connected through keel connectors, and the sliders are arranged on the keels 1 . In this embodiment 2, the main body fixing part 6 is non-adjustable, and the structure of the main body fixing part 6 is as follows Figure 30 As shown, the main body fixing part 6 is provided with a first connection hole 61, the keel 1 and the main body fixing part 6 are connected through the bolt lock 2, and the clip 24 and the lower pressure plate 232 in the bolt lock 2 pass through the main body fixing part 6 The first connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com