A Hall-switch-based system for accurately positioning the initial position of the joint of a robot

A technology of robot joint and positioning system, which is applied in the field of zero position positioning system of robot joints, can solve the problems of reducing zero position positioning accuracy, aging of components and sensitivity to external interference, inability to eliminate the hysteresis of Hall switches, etc., so as to improve positioning The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

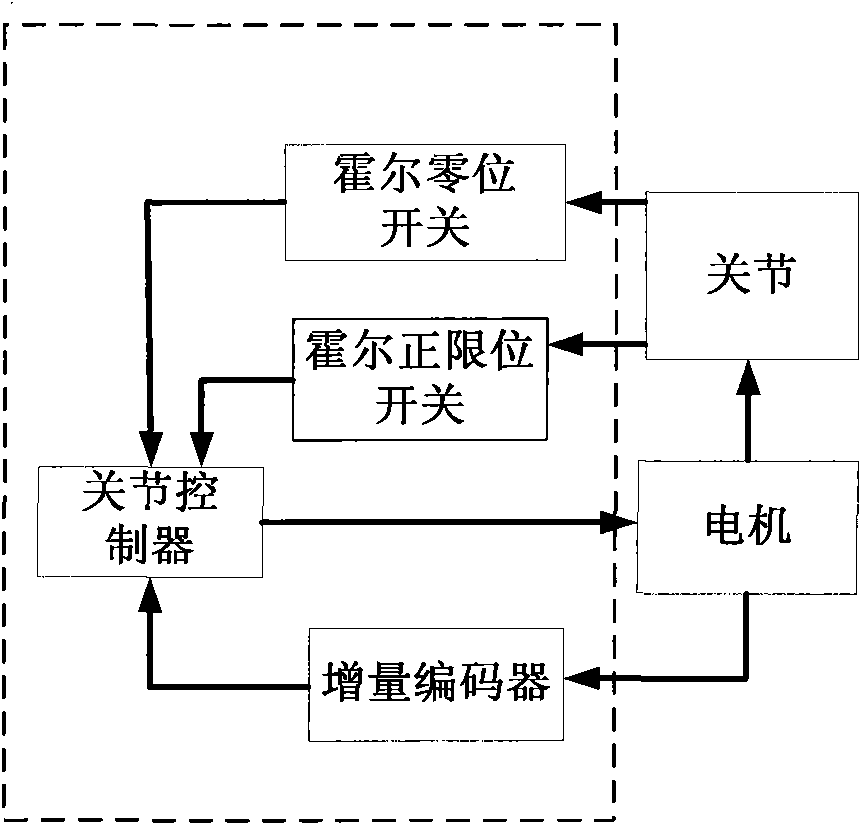

[0066] like figure 1 As shown, the positioning system includes: Hall zero switch, Hall positive limit switch (negative limit switch is also optional), incremental encoder and joint controller. The joint controller determines the motion and position of the joint through the feedback signal of the Hall switch and the incremental encoder.

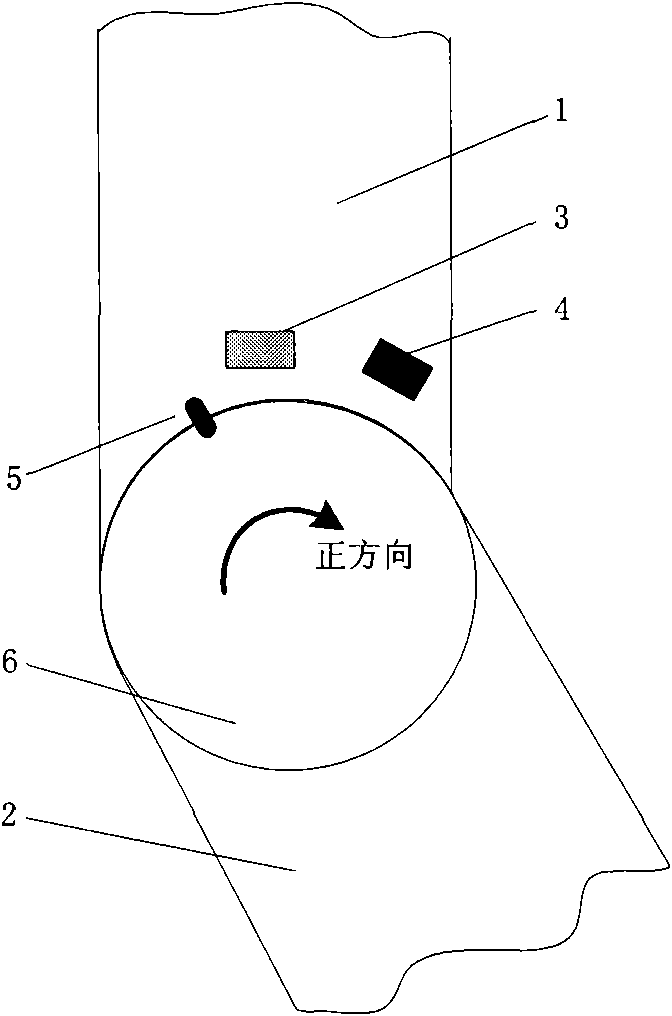

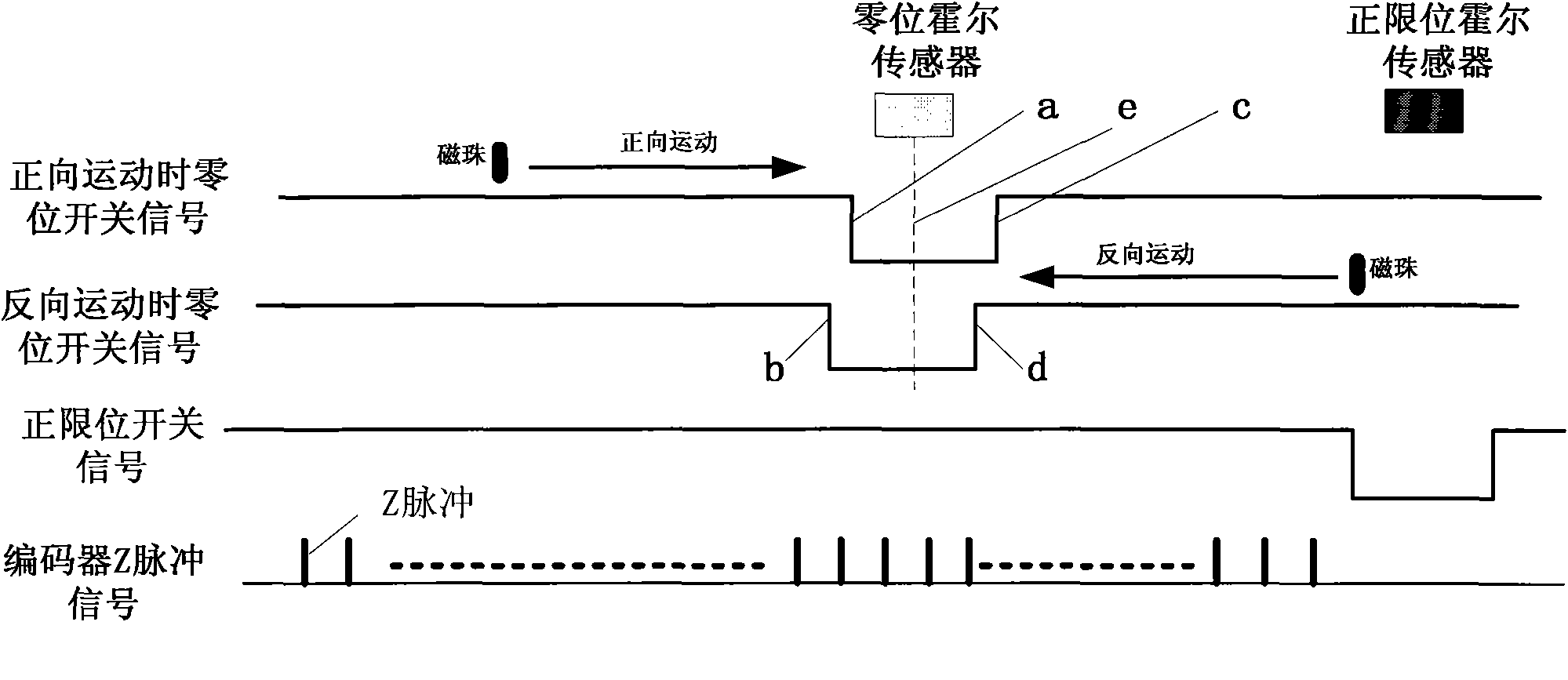

[0067] figure 2 It is the structural diagram of the positioning system, in which the joint is connected to the fixed link 1 and the moving link 2, and the motor drives the joint to rotate to realize the rotation of the link 2; the encoder is connected to the motor shaft 6 to accurately record the rotation angle of the motor and feed it back to the controller , so that the controller can obtain the rotation angle of the joint; the Hall zero position switch is composed of a magnetic bead 5 and a Hall sensor 3, the magnetic bead 5 is installed on the front end of the connecting rod 2, and rotates with the connecting rod 2, and the Hall sensor 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com