Automatic sorting and discharging device

A technology of automatic sorting and movement, applied in the field of machinery, can solve the problems affecting quality, secondary deformation of qualified products, deformation of qualified products, etc., to ensure the quality, improve work efficiency, and avoid operation marks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

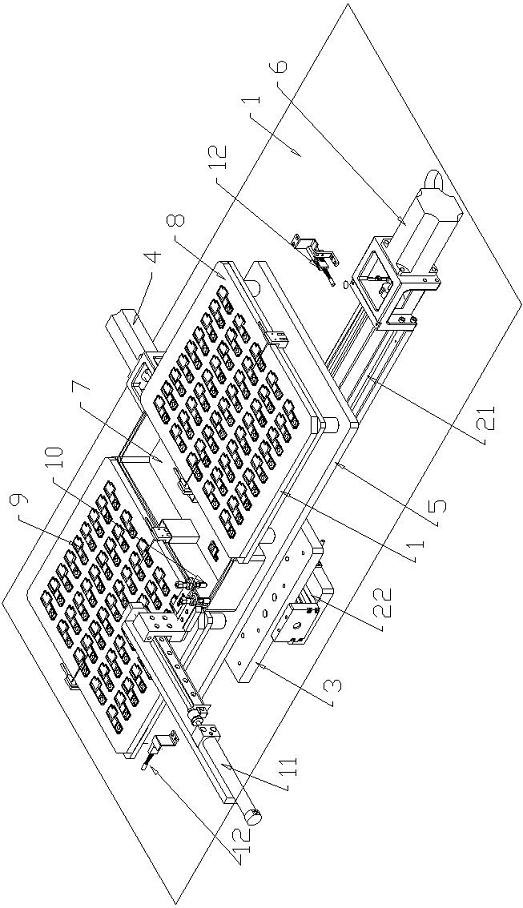

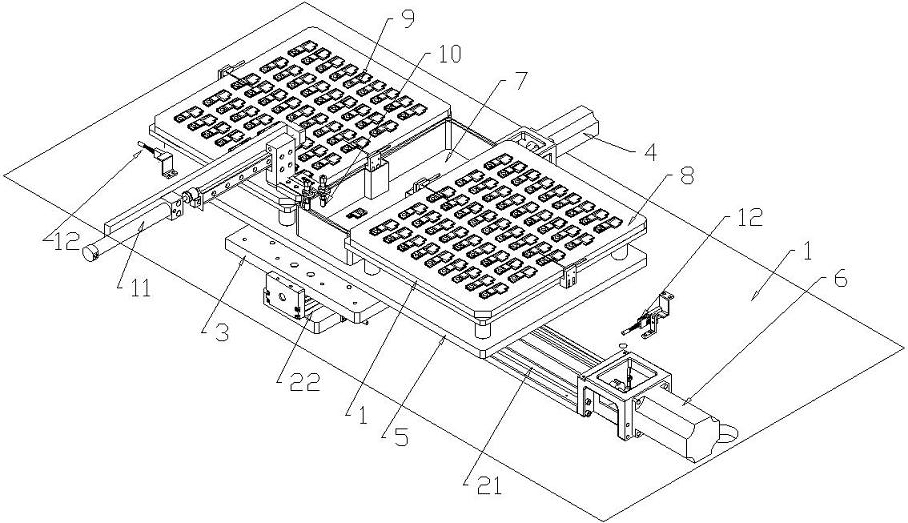

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0022] like figure 1 As shown, the automatic sorting and discharging device of the present invention is arranged on a platform 1, and includes two vertically stacked slide rails 21, 22, and the upper slide rail 21 on the upper floor is fixed on a slide plate 3, and the slide plate 3 is set On the lower slide rail 22, the lower surface of the slide plate 3 is provided with a slideway matched with the slide rail 22, the slide plate 3 is driven by the first servo motor 4 and can move axially along the slide rail 22, and when the slide plate 3 slides Drive the upper slide rail 21 on it to move together. A supporting plate 5 with a larger area is arranged on the upper slide rail 21. The lower surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com