Manufacturing method of blade for centrifugal aeration blower diffuser and positioning tool for same

A manufacturing method and a technology for positioning tooling, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve problems affecting the positioning accuracy of tooling, blades exceeding the assembly gap, roughness and parallelism cannot be guaranteed, and improve processing efficiency , Guarantee the effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

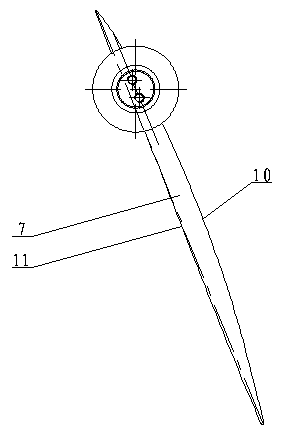

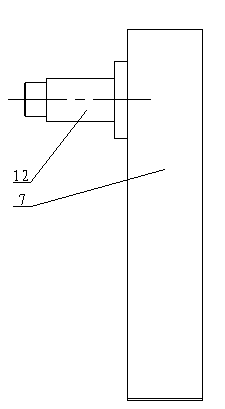

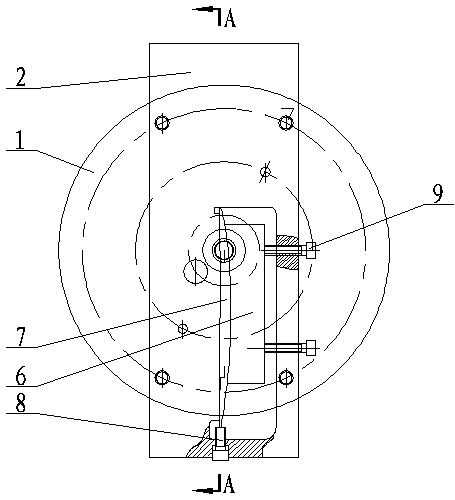

[0020] Embodiment 1: as figure 1 , 2 As shown, a method for manufacturing diffuser blades of a centrifugal aeration blower, the processing steps include: 1) Rough milling of blade squares and process straps; 2) Fine milling of blade profile; 3) Using positioning tooling , wire cutting to remove the process strap; 4), grinding the top surface of the blade; 5), using the positioning tool described in process 3), which is convenient for the lathe to turn the positioning shaft and cut off the end face of the process strap; 6), fitter repair the car Cut the flash and mill the transition radius between the two molded lines at both ends of the blade; 7) Drill the threaded bottom hole on the lathe; 8) The fitter taps the thread and deburrs; 9) Comprehensive inspection. Wherein, in the process 1), the parallelism of the blade rests is less than 0.05 mm.

[0021] In the present invention, process 1) is used as a reference when performing rough milling of the four sides of the blade an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com