Calibrator for cage guide installation

A technology for elevator guide rails and calibrators, applied in the direction of using mechanical devices, instruments, measuring devices, etc., can solve the problems of difficult to guarantee installation quality, poor consistency, time-consuming, etc., and achieve strong practicability, reduced experience requirements, and reduced installation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Describe the present invention below in conjunction with specific embodiment:

[0024] In this embodiment, a calibrator is used to calibrate the verticality, twist and alignment of the elevator guide rail 10 during the installation process.

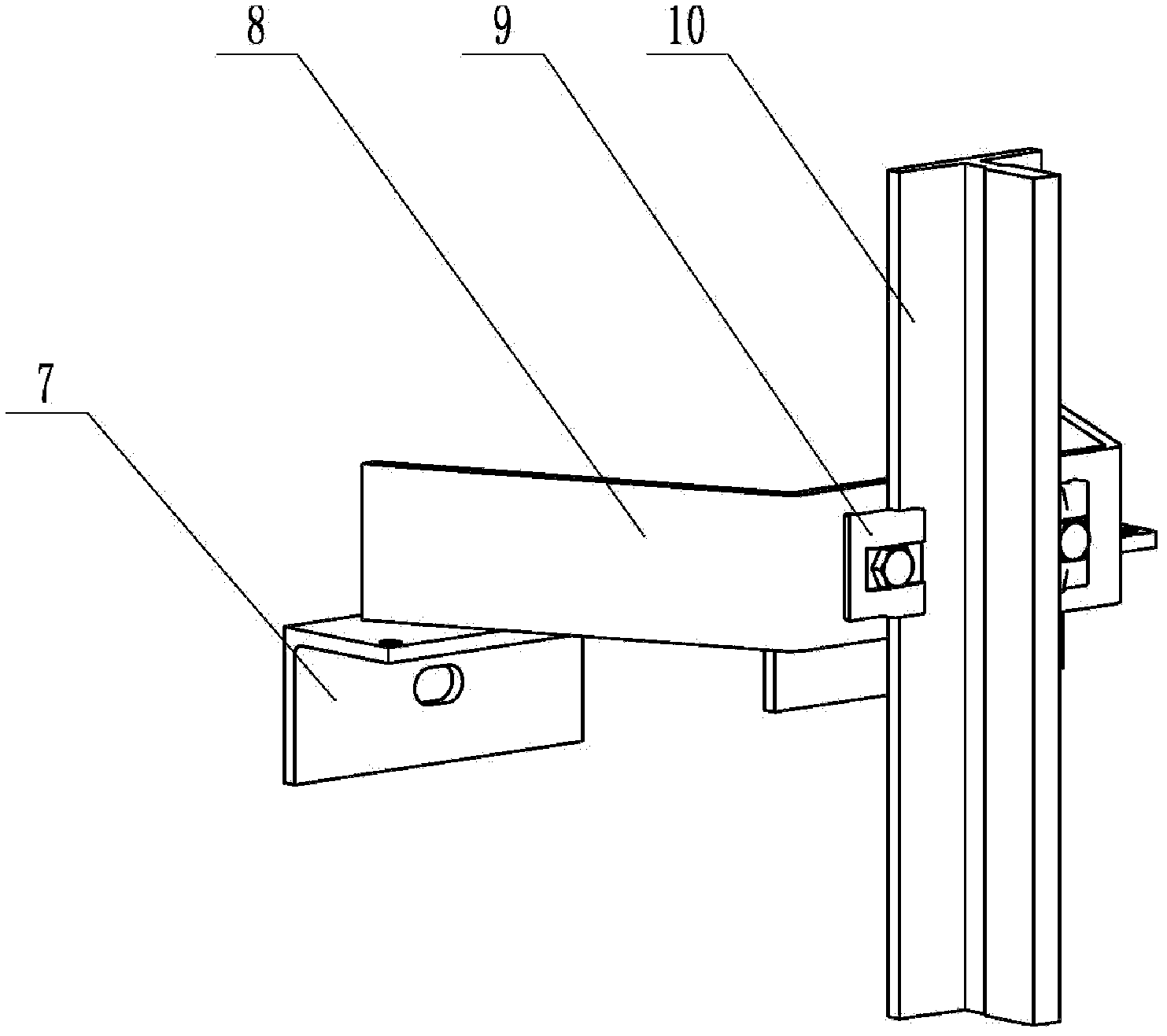

[0025] Refer to attached figure 1 And attached image 3 , Elevator guide rail 10 is installed on the yard support 7 that is fixed on the wall by pressing plate 9 and octagonal bracket 8.

[0026] Refer to attached figure 1 , the calibrator in this embodiment mainly includes a detection scale II and a calibration mechanism III. In addition, in order to better realize functions, the calibrator also includes a rotating bracket IV.

[0027] Refer to attached figure 1 And attached figure 2 , the detection scale is fixed on the guide rail, which is a key component for detecting the verticality, twist and alignment of the guide rail. The measuring scale comprises a first knife-edge ruler 1, a second knife-edge ruler 4, a third knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com