Holing and fertilizing combine for transplanting

An all-in-one machine and fertilizer applicator technology, applied in the field of agricultural machinery, can solve the problems of inability to meet the needs of transplanting agronomy, poor hole-forming function, small hole-forming depth and diameter, etc., so as to improve the transplanting efficiency, survival rate, and institutional structure. Simple, labor-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

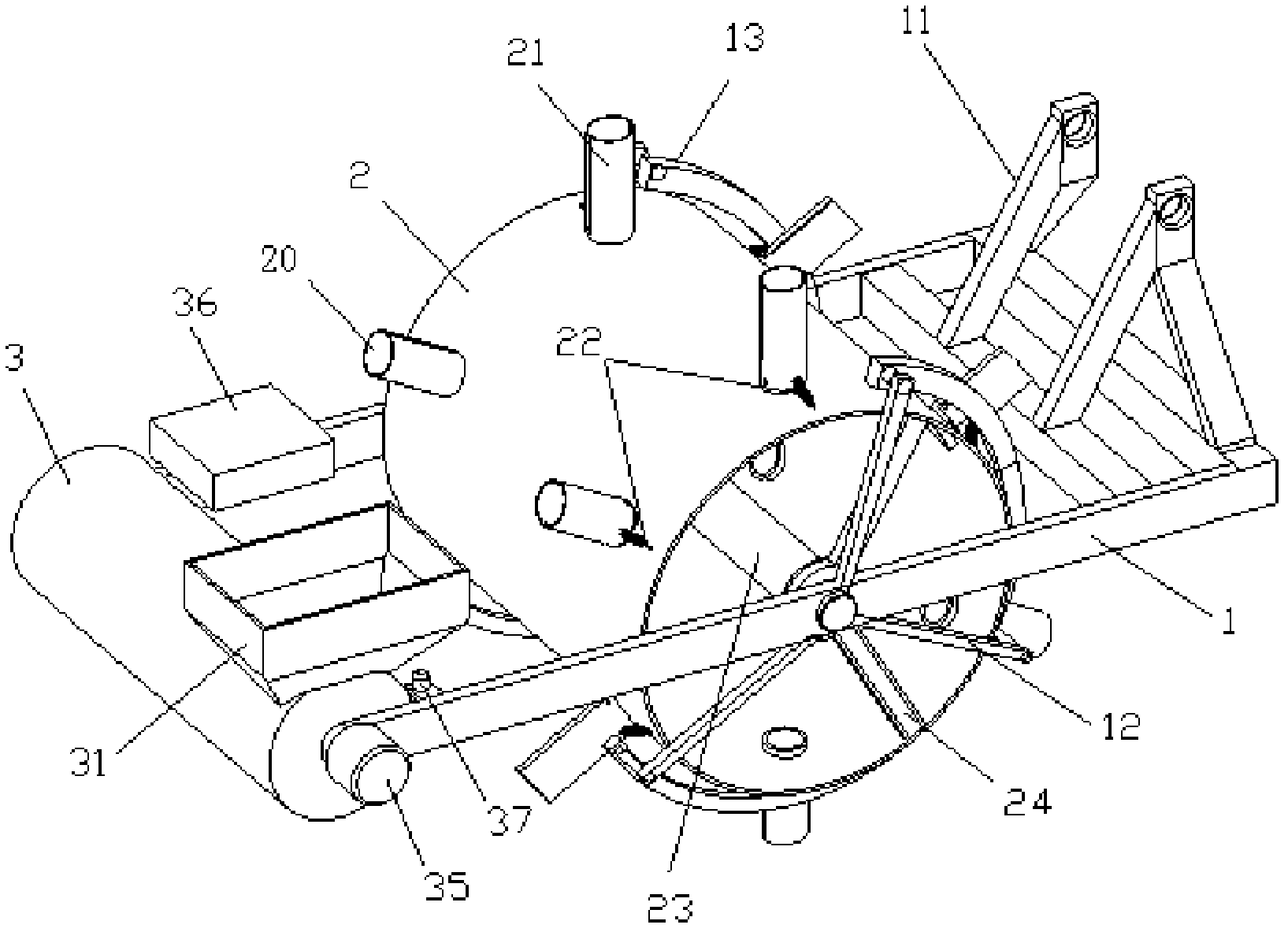

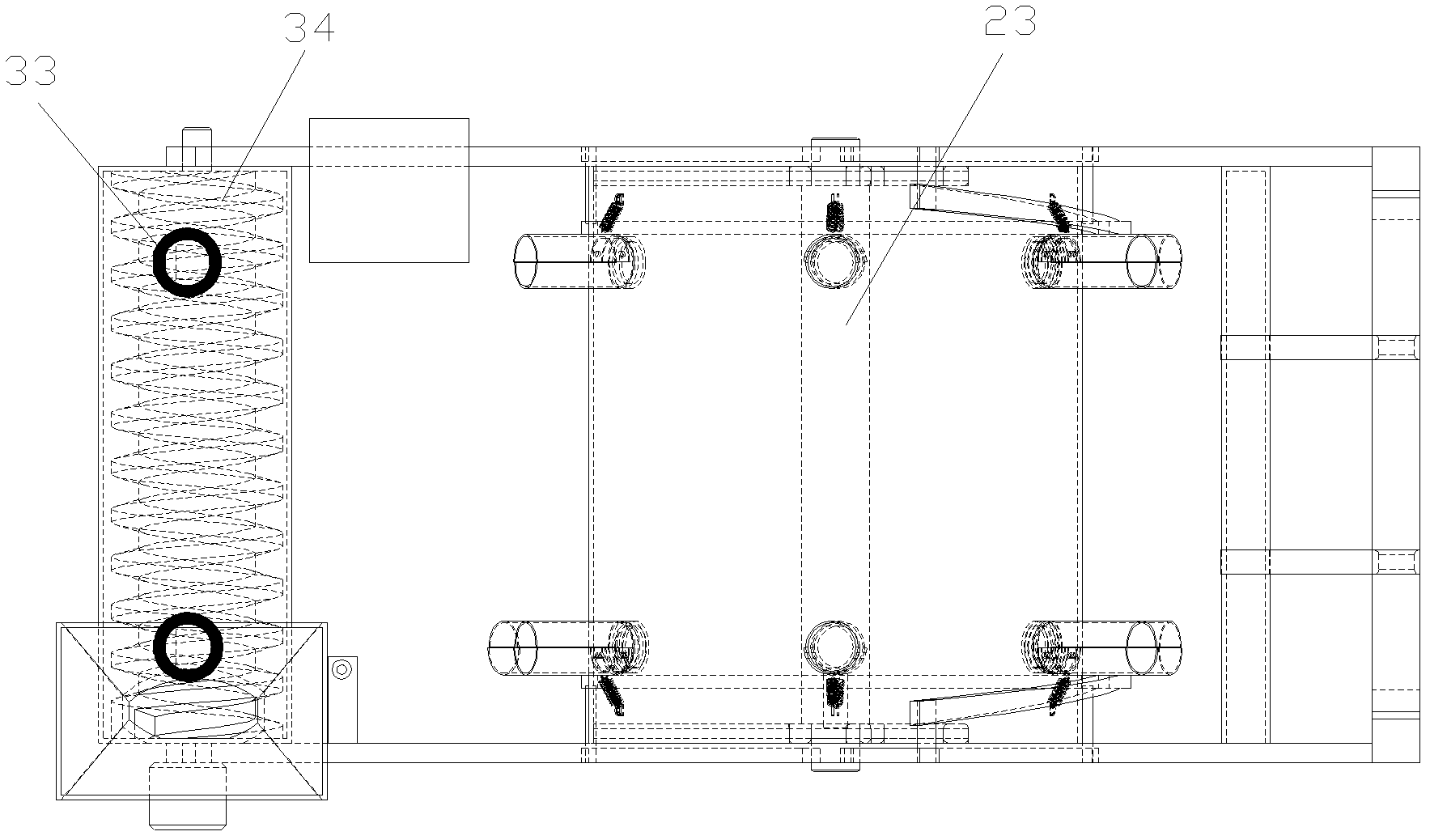

[0033]The all-in-one machine for fertilizing and punching holes for transplanting adopted by the present invention includes a frame 1, a hole-rolling cylinder 2 and a fertilizer applicator 3, and the hole-rolling cylinder 2 and the fertilizer applicator 3 are all arranged on the frame 1, and the frame 1 is close to the hole-rolling cylinder The end of 2 is provided with two symmetrically arranged connecting frames 11, through which the integrated fertilization and drilling machine can be connected to the tractor for work; , and three roller poles 24 are provided in the hole roller 2 to increase the firmness of the hole roller 2; the outer surface of the hole roller 2 is provided with 2 rows of cutters on the circumference, and each row of cutters consists of 3 A fertilization hole cutter 20 and 3 tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com