Additive-free fermented milk and preparation method thereof

An additive-free, fermented milk technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of insufficient flavor of flavor-free fermented milk, achieve the effect of overcoming thin texture and insufficient flavor, and reducing the burden of metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

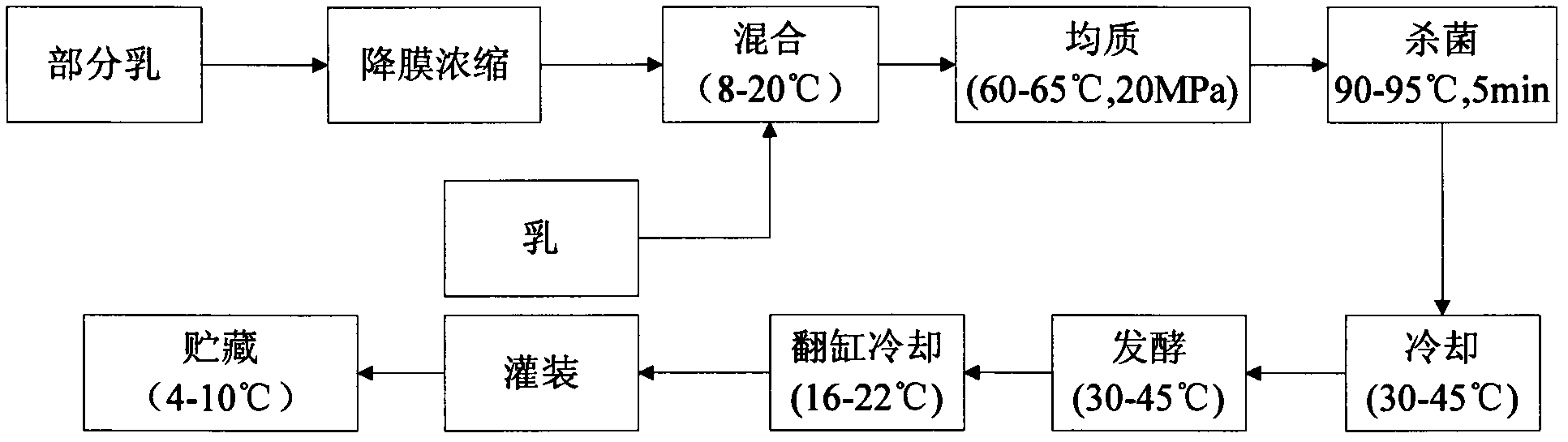

Method used

Image

Examples

Embodiment 1

[0033] Additive-free fermented milk raw materials: cow milk, Guangming Dairy Co., Ltd.; YFL900-1 (Lactobacillus bulgaricus, Streptococcus thermophilus and Lactococcus lactis), Danisco Strains Co., Ltd.

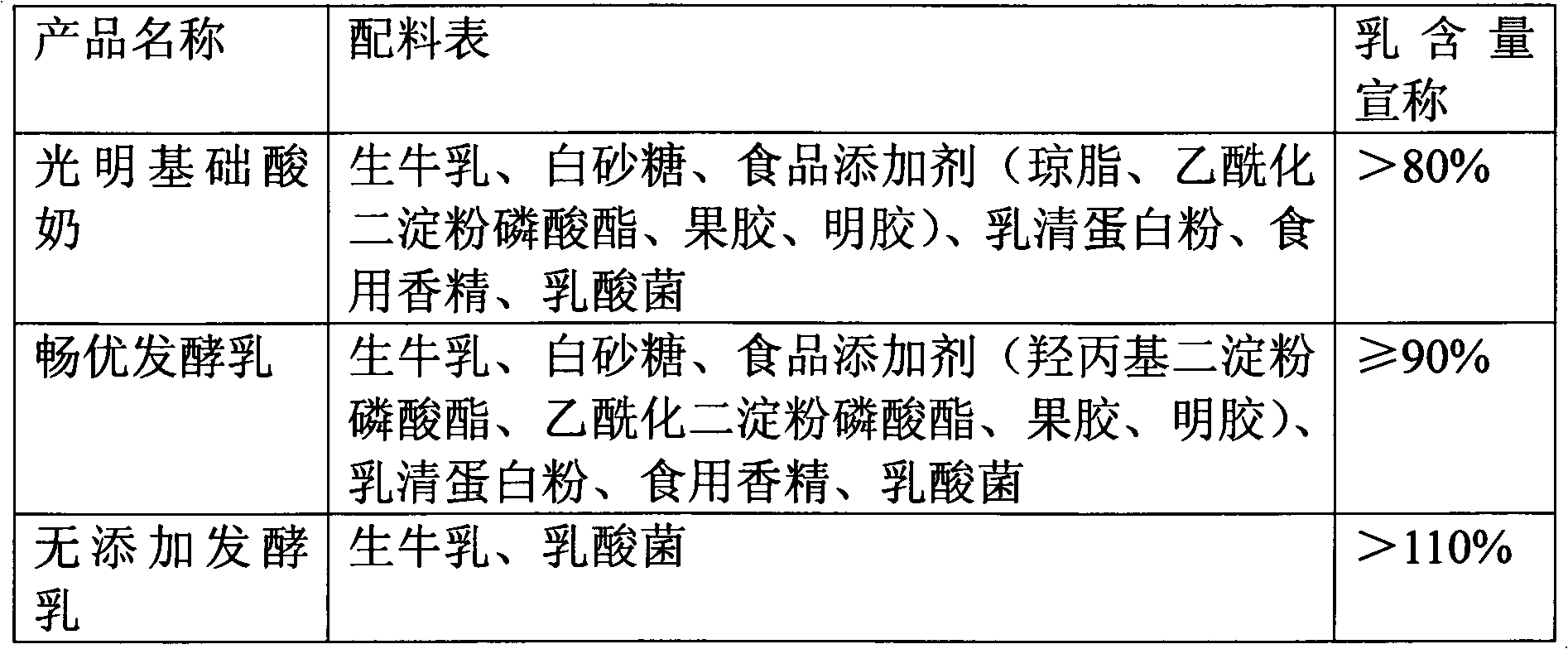

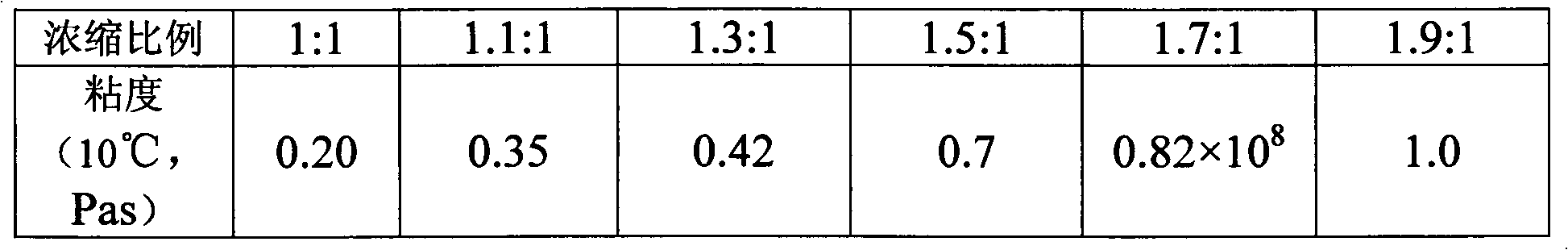

[0034] The preparation method of fermented milk without additives: 1450kg of milk with a protein content of 2.8% and a fat content of 3.1% is processed by a single-effect falling film concentration process. With a boiling point of 85°C, concentrated milk with a protein content of 4.06% and a fat content of 4.5% was obtained; 60-65°C, homogenized at 18-20MPa; sterilized at 90-95°C for 5 minutes, cooled to 42°C; adding strains (Lactobacillus bulgaricus 5 ×10 5 cfu / g, Streptococcus thermophilus 5×10 5 cfu / g / , Lactococcus lactis 5×10 7 cfu / g); ferment at 42°C until the final acidity is 90°T; turn over the tank and cool to 16-22°C; fill; refrigerate (4-10°C) to obtain 1000kg of fermented milk without additives.

Embodiment 2

[0036] Additive-free fermented milk raw materials: cow milk, Guangming Dairy Co., Ltd.; YFL900-2 (Lactobacillus bulgaricus, Streptococcus thermophilus and Lactococcus lactis), Danisco Strains Co., Ltd.

[0037]The preparation method of fermented milk without additives: 1100kg of milk with a protein content of 3.18% and a fat content of 3.18% is processed through a double-effect falling film concentration process, the vacuum degree of the first-effect concentration is 5bar, the boiling point temperature is 82°C, and the vacuum degree of the second-effect concentration is 7.2 bar, evaporating boiling point 70°C, concentrated according to the ratio of 1.1:1 (mass ratio before and after concentration), to obtain concentrated milk with a protein content of 3.5% and a fat content of 3.5%; 60-65°C, 18-20MPa homogeneous; 90-95°C Sterilize for 6 minutes, cool to 32°C; add strains (Lactobacillus bulgaricus 5×10 7 cfu / g, Streptococcus thermophilus 5×10 7 cfu / g, Lactococcus lactis 1×10 ...

Embodiment 3

[0039] Additive-free fermented milk raw materials: cow milk, Guangming Dairy Co., Ltd.; DAHI (Lactobacillus bulgaricus, Streptococcus thermophilus and Lactococcus lactis), Danisco Strains Co., Ltd.

[0040] The preparation method of fermented milk without adding: 300kg of milk with a protein content of 2.8% and a fat content of 3.1% is processed through a single-effect falling film concentration process, concentrated according to the ratio of 1.8:1 (mass ratio before and after concentration), and the vacuum degree is 9.1bar. Boiling point of evaporation is 50°C, mixed with 700kg of milk with protein content of 2.8% and fat content of 3.1%; 60-65°C, 18-20MPa homogeneous; sterilized at 90-95°C for 5 minutes, cooled to 32°C; added strains (Lactobacillus bulgaricus 5×10 7 cfu / g, Streptococcus thermophilus 5×10 7 cfu / g, Lactococcus lactis 1×10 5 cfu / g); ferment at 45°C until the final acidity is 110°T; turn over the tank and cool to 16-22°C; fill; refrigerate (4-10°C) to obtain 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com