Splicing flange leveling device of wind driven generator tower cylinder

A wind turbine and flange-connecting technology, applied in the field of mechanical processing, can solve the problem of no leveling device, etc., and achieve the effect of ensuring quality, improving correction effect and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

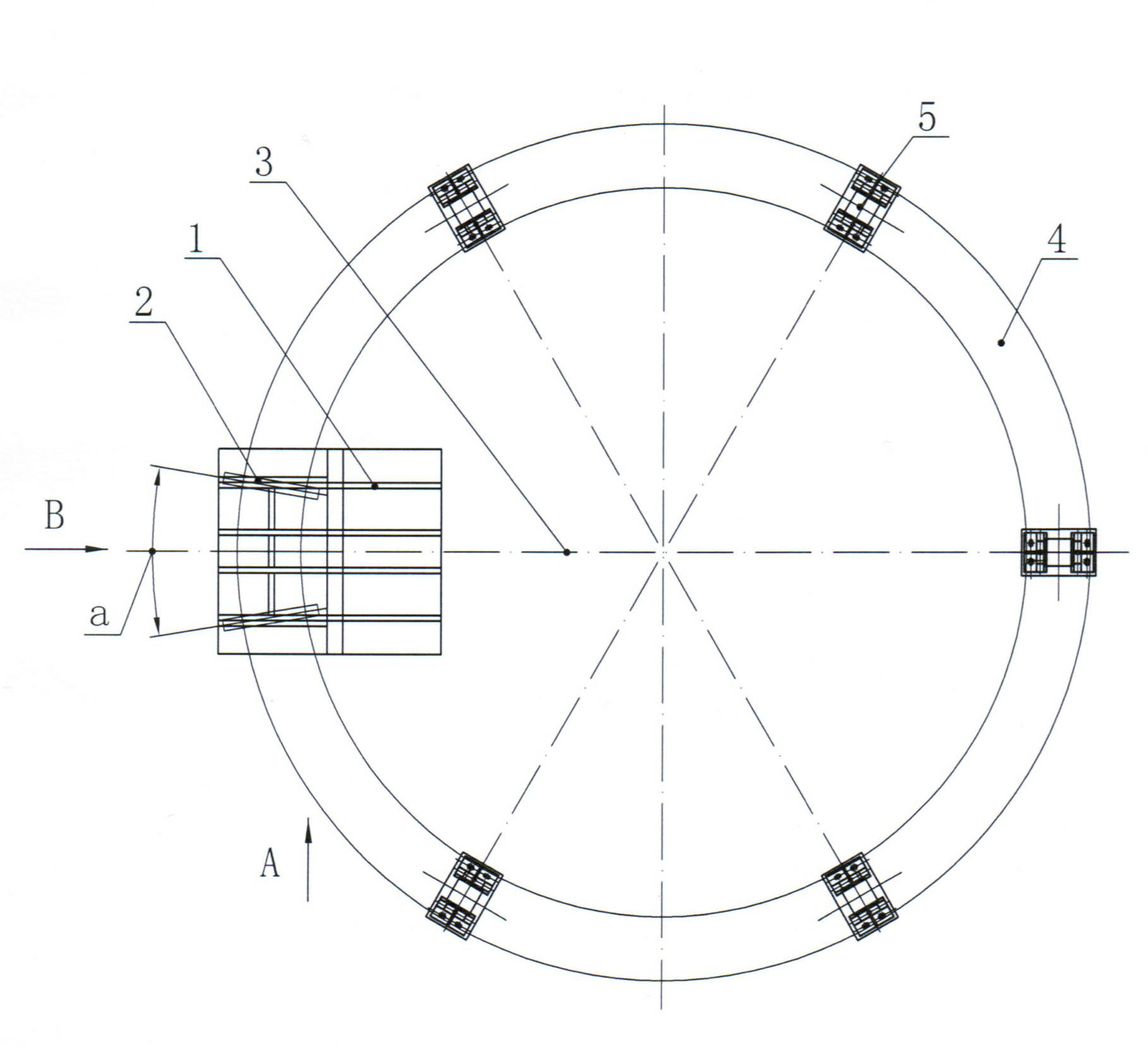

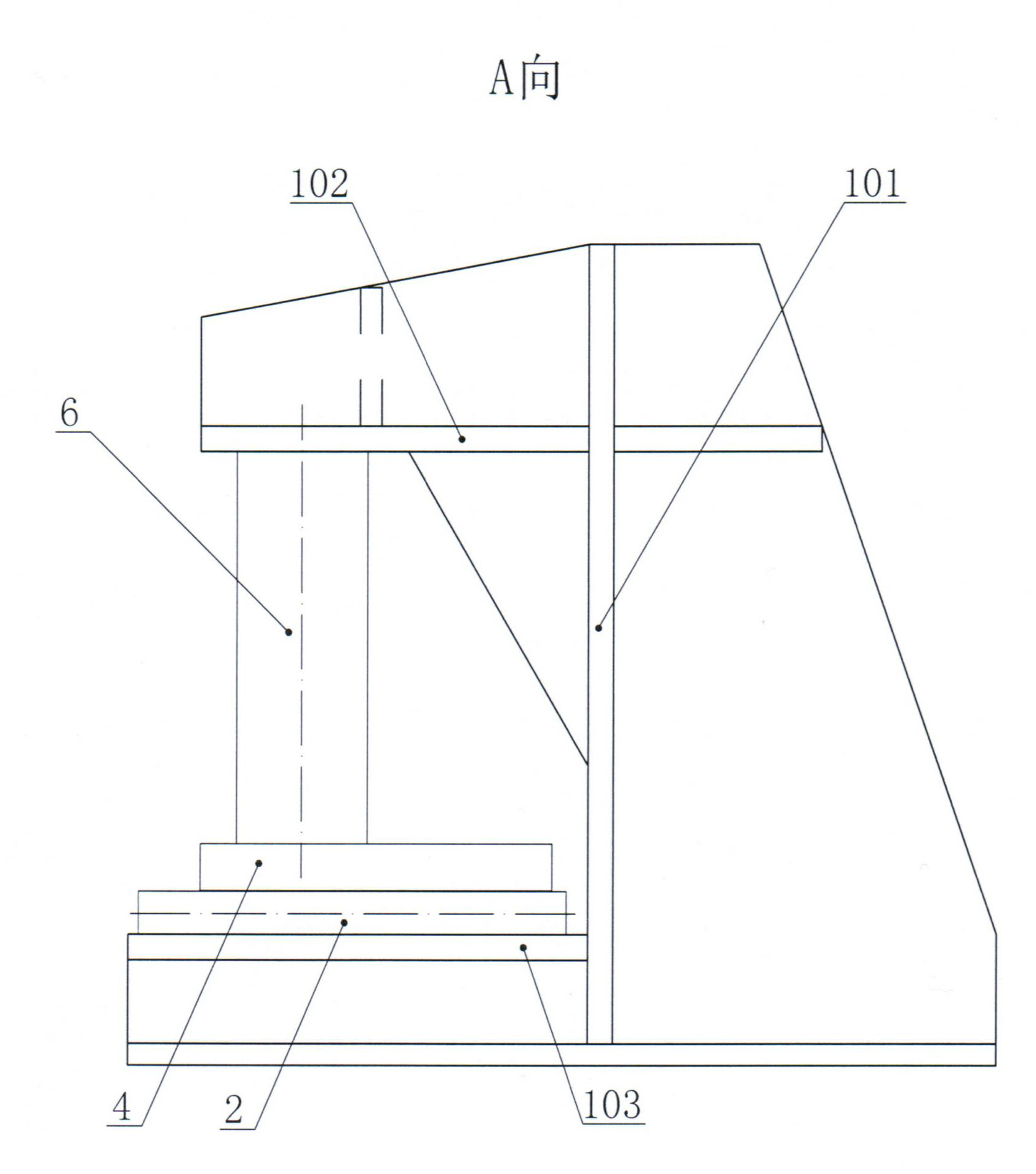

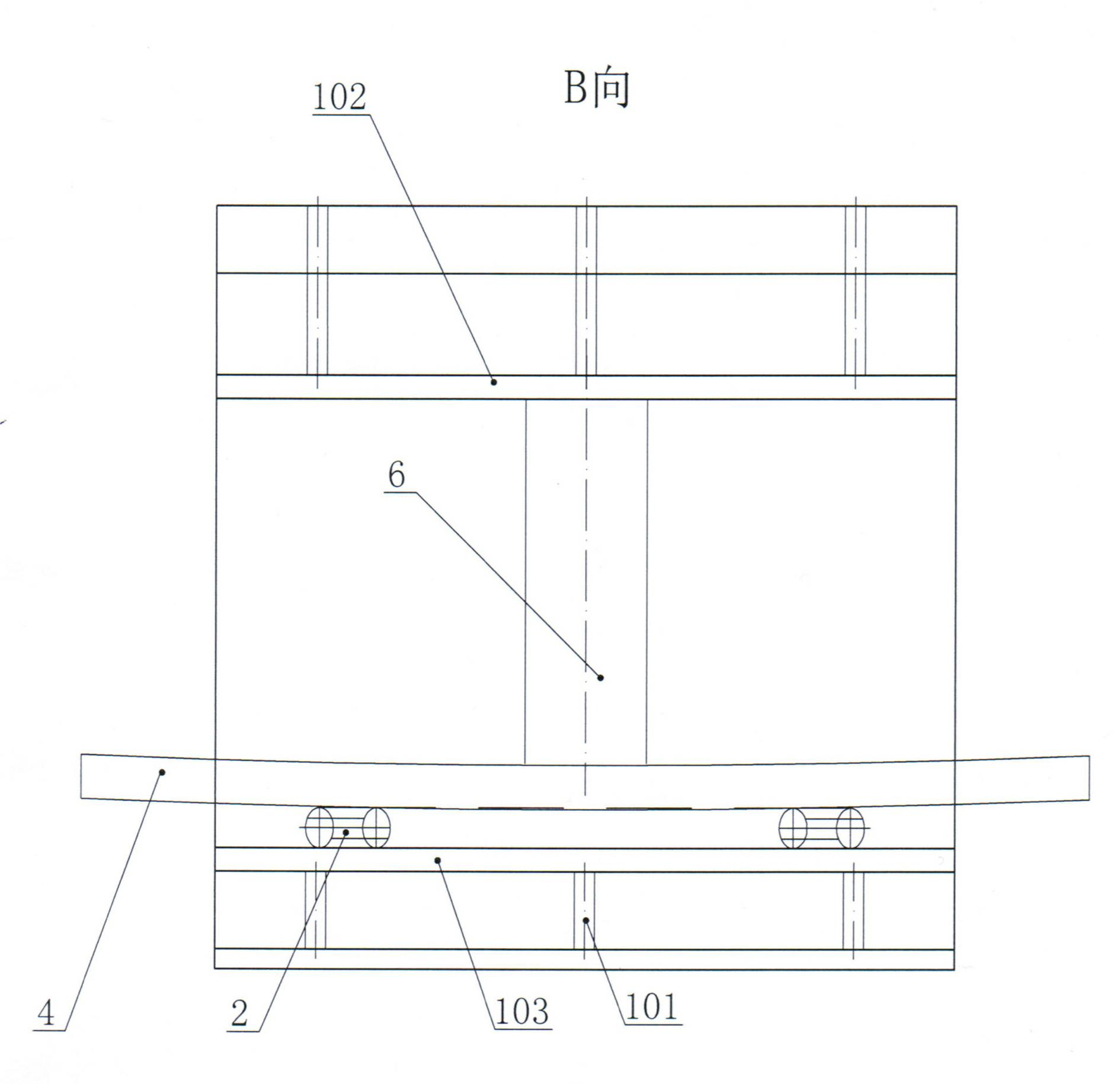

[0026] Such as Figure 1~3 As shown, a wind turbine tower splicing flange leveling device includes a frame 1, a hydraulic jack 6 and a support 2, and the splicing flange 4 is located between the hydraulic jack 6 and the support 2; The frame 1 includes a column 101, an upper beam 102 and a lower beam 103, and the upper beam 102 and the lower beam 103 are fixedly connected to the column 101; the above-mentioned support 2 is located on the lower beam 103, and the support 2 is located on the spliced flange leveling On both sides of the device axis 3; the hydraulic jack 6 is located between the splicing flange 4 and the upper beam 102.

[0027] The support members 2 in this embodiment can be two, three, four or more.

[0028] If two support members 2 are selected, the two support members 2 are symmetrically distributed on both sides of the axis 3 of the splicing flange leveling device. In use, the area formed by the two supports 2 surrounds the area to be leveled.

[0029] If ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com