Arm support structure, arm support device and concrete pump truck

A boom and driving device technology, applied in building construction, building material processing, construction, etc., can solve the problems of dead center of cloth, large volume and weight, large inertia, etc., so as to improve the flexibility of cloth and meet the function requirements, the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] In the following description, many specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways different from those described here, therefore, the present invention is not limited to the specific embodiments disclosed below limit.

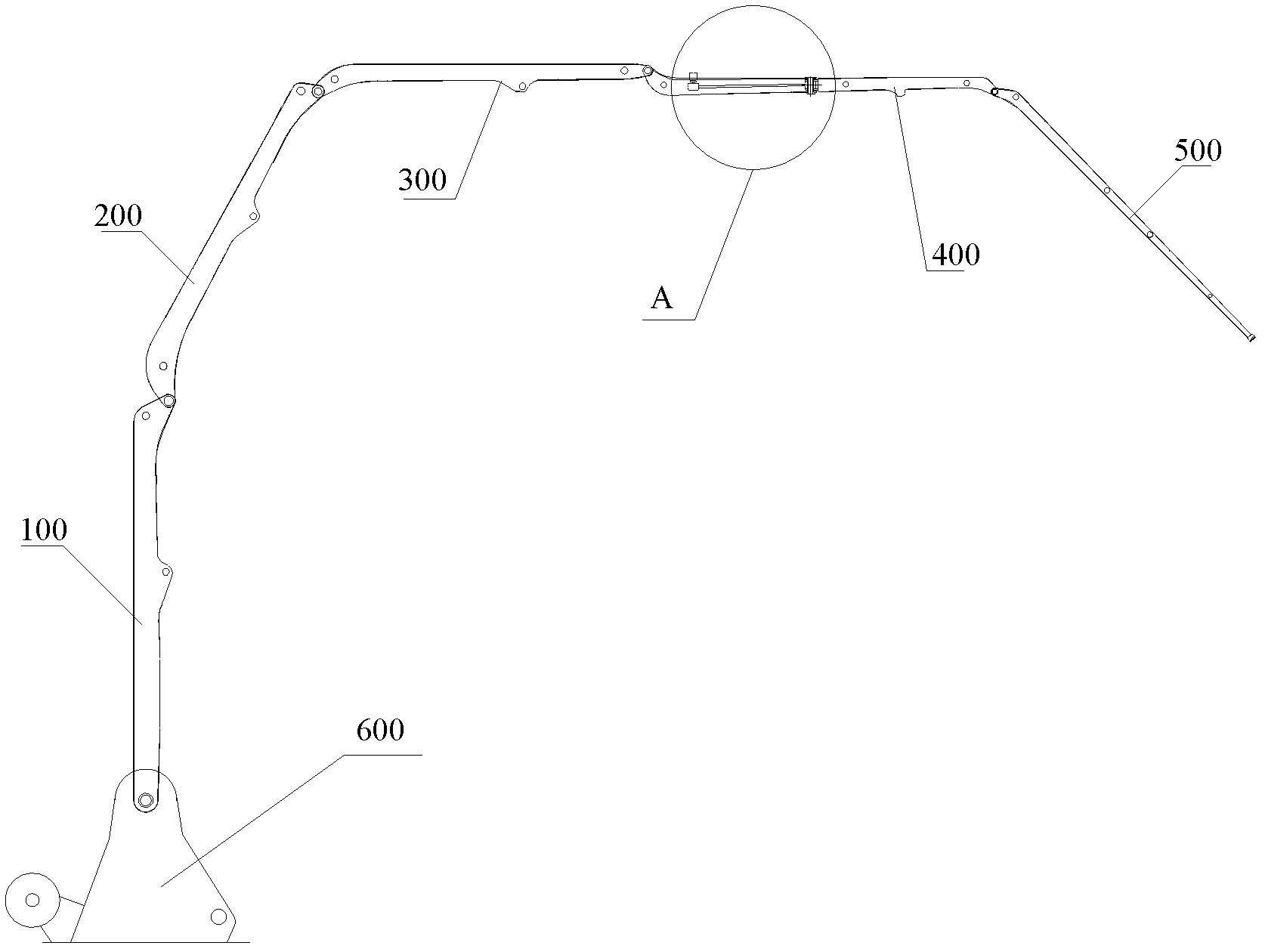

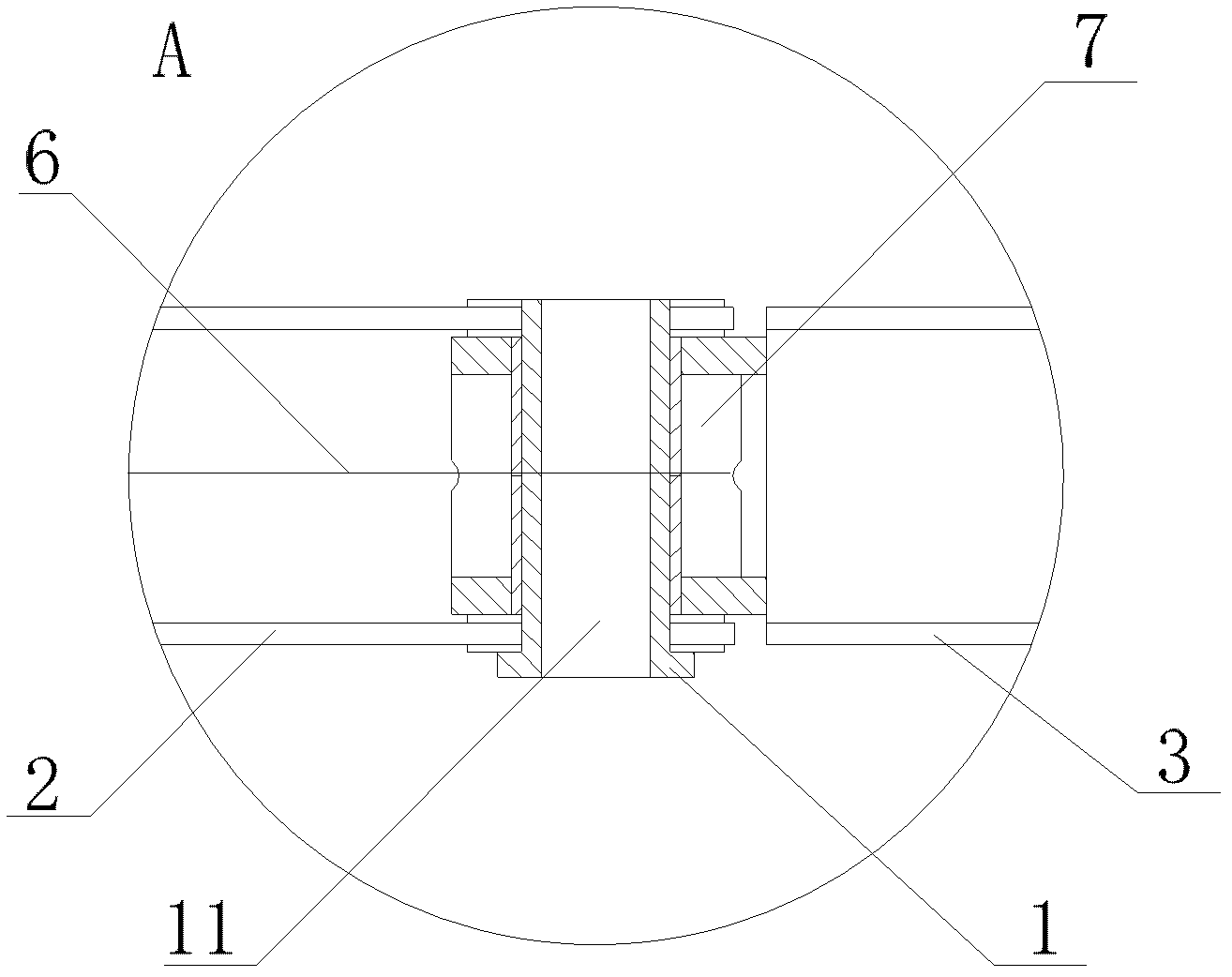

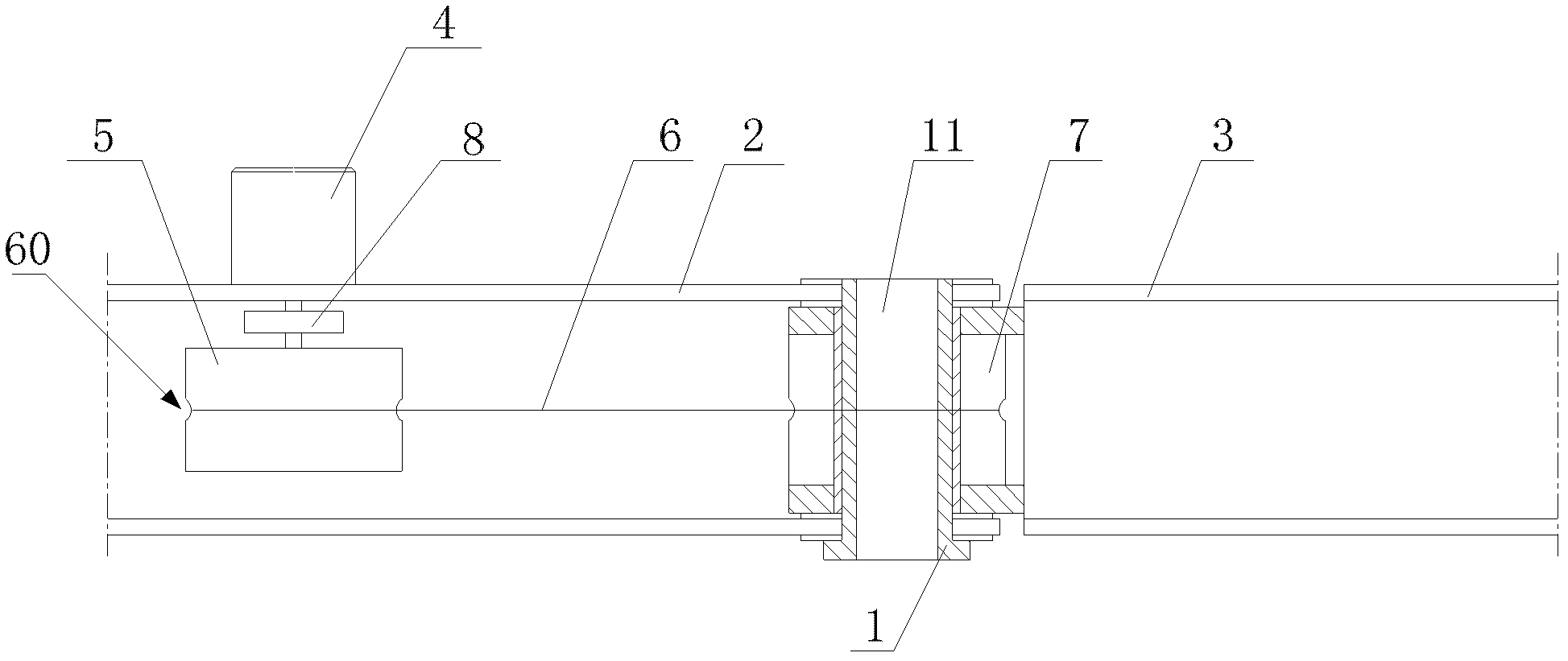

[0039] Such as Figure 1 to Figure 3 As shown, the present invention provides a boom device, which includes multi-section five-section booms hinged in sequence, the first section boom 100, the second section boom 200, the third section boom 300, the fourth section boom 400 and the fifth section boom. The joint arms 500 are hinged sequentially, and the root end of the first joint arm 100 is hinged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com