Method for simply and easily calibrating industrial robot

An industrial robot and calibration method technology, which is applied in the field of simple calibration of industrial robots, can solve problems such as poor positioning accuracy, and achieve the effects of practical positioning accuracy, wide and flexible application, and practical repeated positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

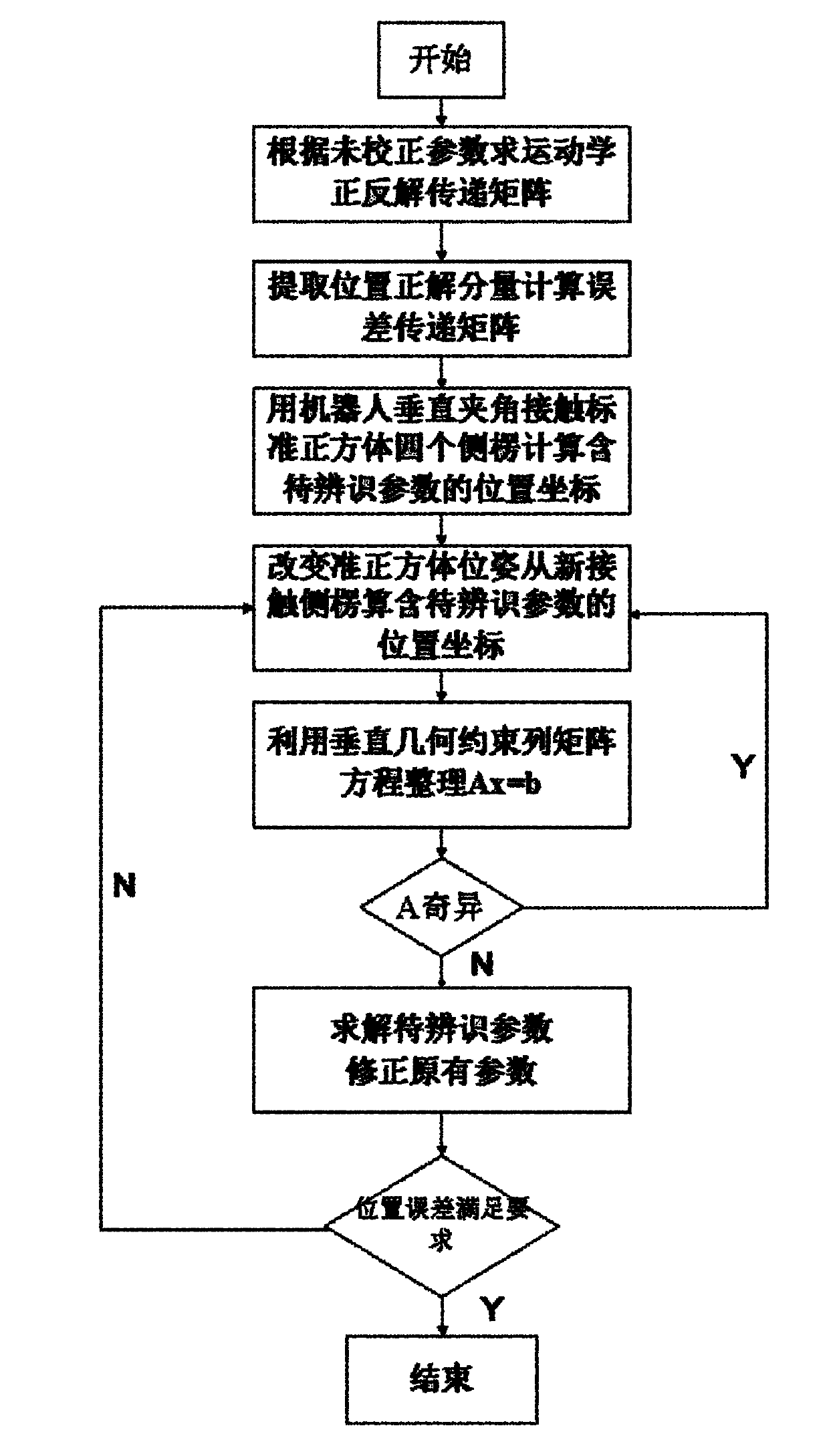

[0034] like figure 1 As shown, the simple calibration method for industrial robots of the present invention includes the following steps:

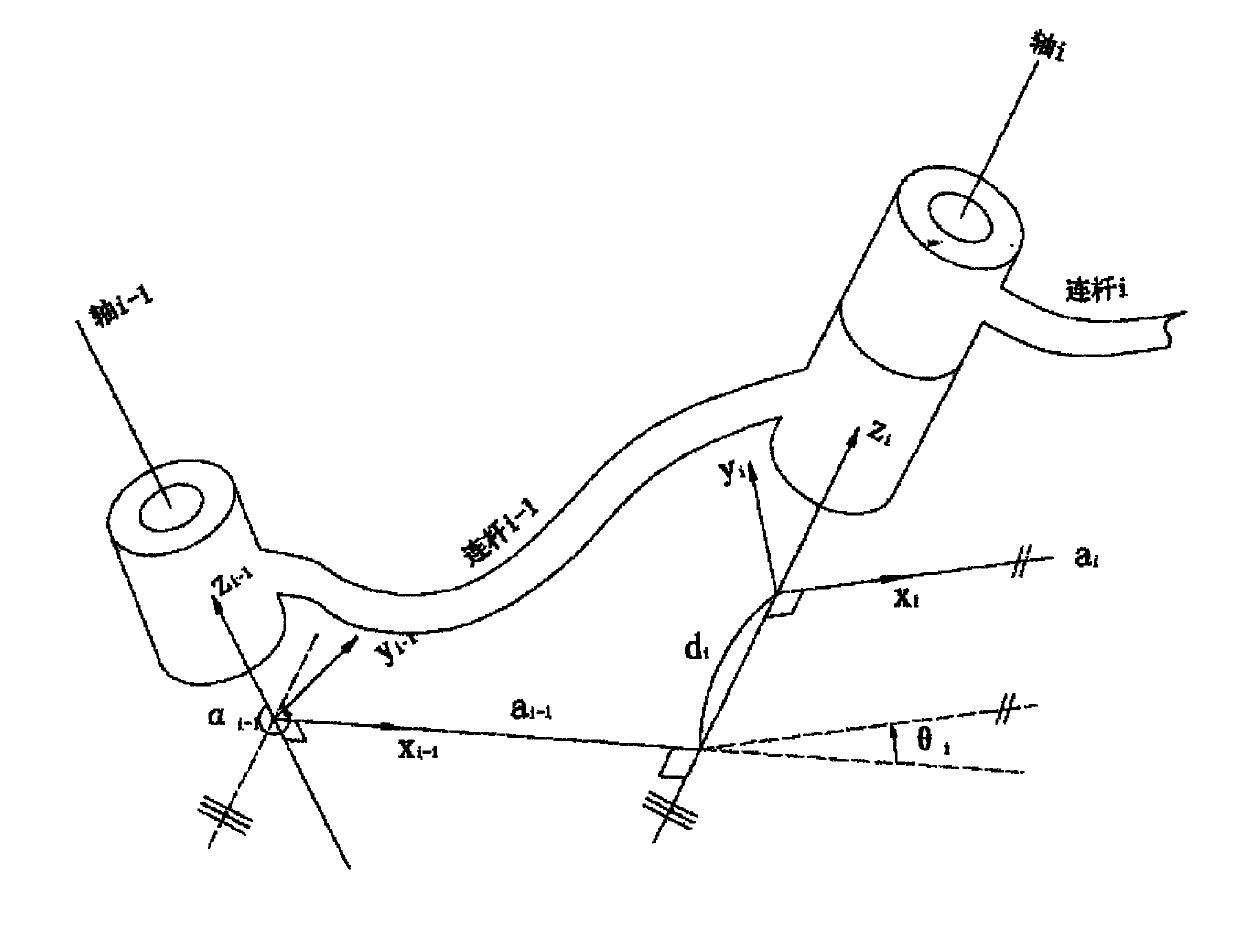

[0035] According to the improved DH method, the industrial robot kinematics model is established, and the parameters of the industrial robot before calibration are used to obtain the transfer matrix of the robot kinematics and attitude;

[0036] Extract the robot end position component from the robot kinematics attitude transfer matrix, and calculate the error transfer matrix by using the full differential form of the position component;

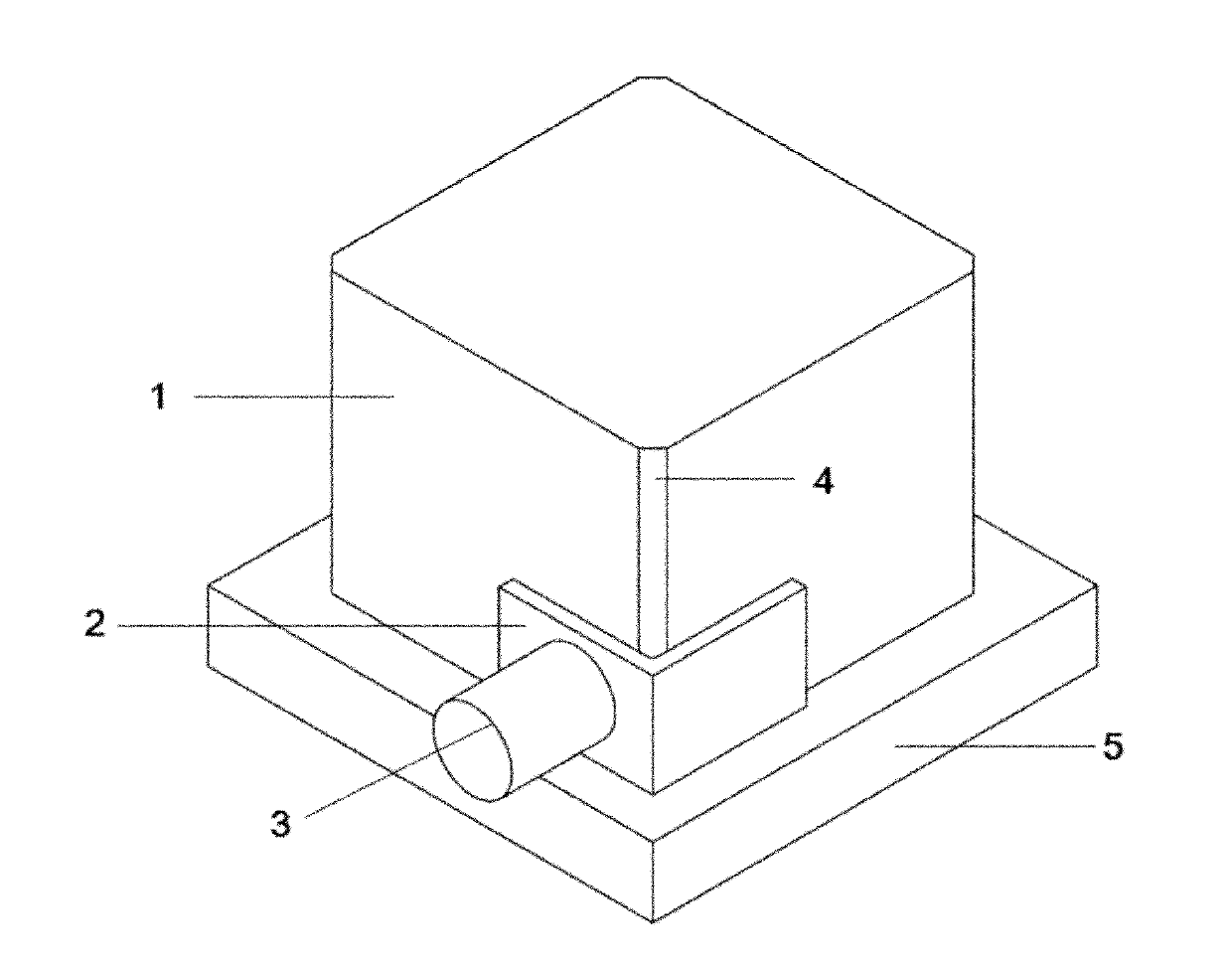

[0037] Operate the end tool of the robot (a jig with two sides perpendicular to each other), make the jig touch the four sides of the standard cube pre-placed in the robots workspace, read the number of code discs of each joint of the robot, and use the error transfer matrix to calculate the position containing the parameters to be identified coordinate;

[0038] Change the pose of the standard cube in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com