Camera capable of achieving long-range shooting and super macro shooting

A camera and ultra-micro technology, applied in the field of cameras, can solve the problems of unable to observe distant targets, unable to obtain clear images, unable to install close-up mirrors or close-up rings, etc., to achieve the effect of expanding the shooting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

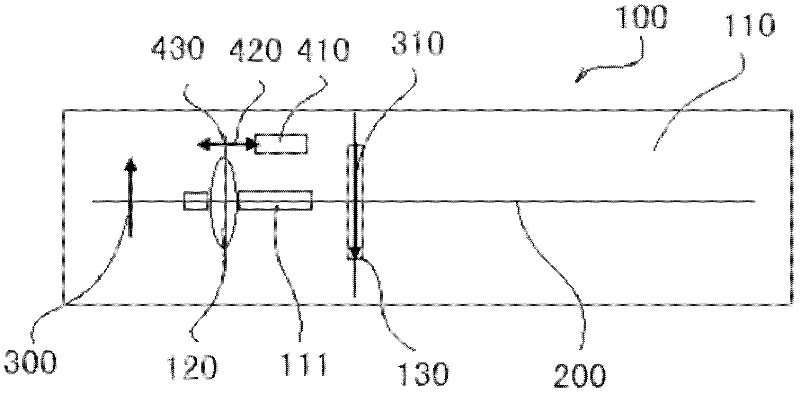

[0034] The video camera of this embodiment capable of both telephoto shooting and ultra-macro shooting includes a camera module 100 and other components with the same structure as the existing video camera. see figure 1 , its camera module 100 includes a module housing 110, an optical lens assembly 120, and an imaging target surface assembly 130, and an optical lens assembly chute 111 parallel to the optical axis 200 of the camera module is arranged on the module housing 110, and An optical lens assembly slider (not shown) is arranged on the optical lens assembly 120, the optical lens assembly 120 is slidably arranged in the module housing 110, and the optical lens assembly slider on it is embedded in the optical lens assembly chute In 111, an optical lens assembly drive mechanism is provided in the module housing 110, so that the optical lens assembly 120 can move along the camera module optical axis 200 under the drive of the optical lens assembly drive mechanism, thereby ac...

Embodiment 2

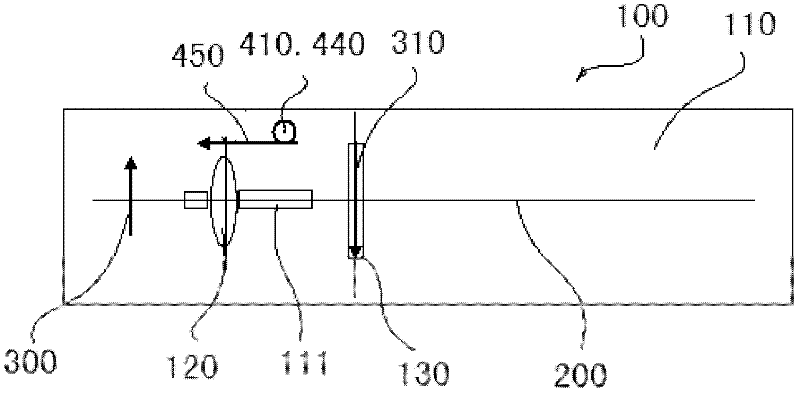

[0037] The difference between the video camera of this embodiment that can realize both telephoto shooting and ultra-macro shooting is different from that of Embodiment 1 in that the driving mechanism of the optical lens assembly is different, and the rest is the same as that of Embodiment 1.

[0038] see figure 2 , the optical lens assembly driving mechanism of this embodiment includes an optical lens assembly driving servo motor 410 and an optical lens assembly driving gear 440 connected to the output shaft of the optical lens assembly driving servo motor 410 and an optical lens assembly driving rack 450, the optical The lens assembly driving rack 450 meshes with the optical lens assembly driving gear 440 on the one hand, and is connected with the optical lens assembly 120 on the other hand. The optical lens assembly driving servo motor 410 is controlled by the width of a pulse signal output by the signal generating unit, and the signal generating unit is controlled by the ...

Embodiment 3

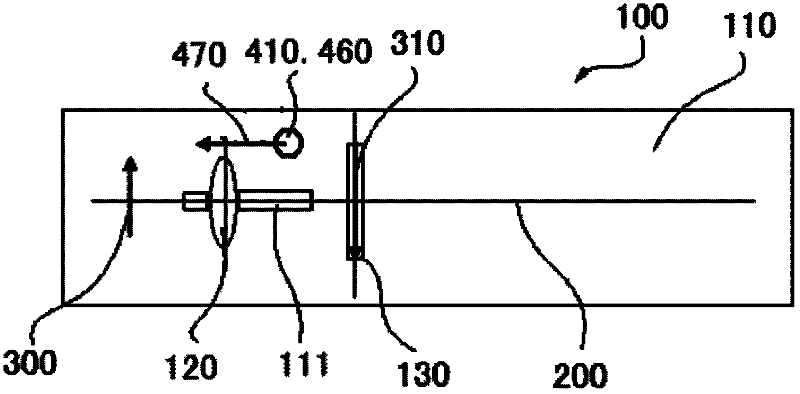

[0040] The difference between the video camera of this embodiment that can realize both telephoto shooting and ultra-macro shooting is different from that of Embodiment 1 in that the driving mechanism of the optical lens assembly is different, and the rest is the same as that of Embodiment 1.

[0041] see image 3 , the optical lens assembly driving mechanism of this embodiment includes an optical lens assembly driving servo motor 410 and an optical lens assembly driving wheel 460 connected to the output shaft of the optical lens assembly driving servo motor 410 and an optical lens assembly driving link 470, the optical lens assembly One end of the lens assembly driving link 470 is eccentrically connected to the optical lens assembly driving wheel 460 , and the other end is connected to the optical lens assembly 120 . The optical lens assembly driving servo motor 410 is controlled by the width of a pulse signal output by the signal generating unit, and the signal generating un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com