Wobble bearing type friction test device and method

The technology of a test device and a test method is applied in the field of a rocking bearing type friction test device to achieve the effects of stable pressure load, simple structure and convenient test operation.

Inactive Publication Date: 2012-06-27

SANY HEAVY MACHINERY

View PDF5 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the research on rocking bearing friction at home and abroad is still in the rolling friction of the en

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

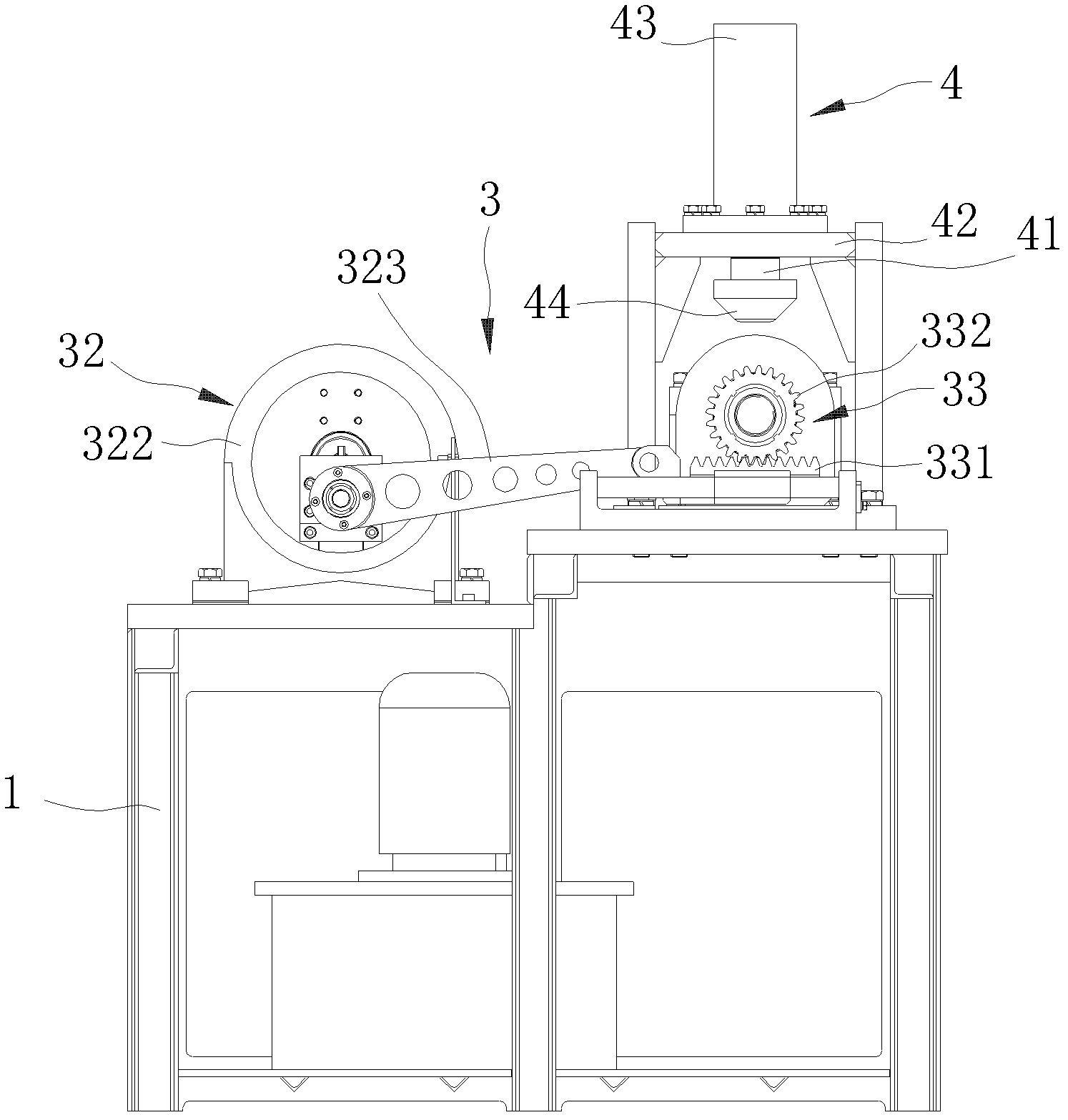

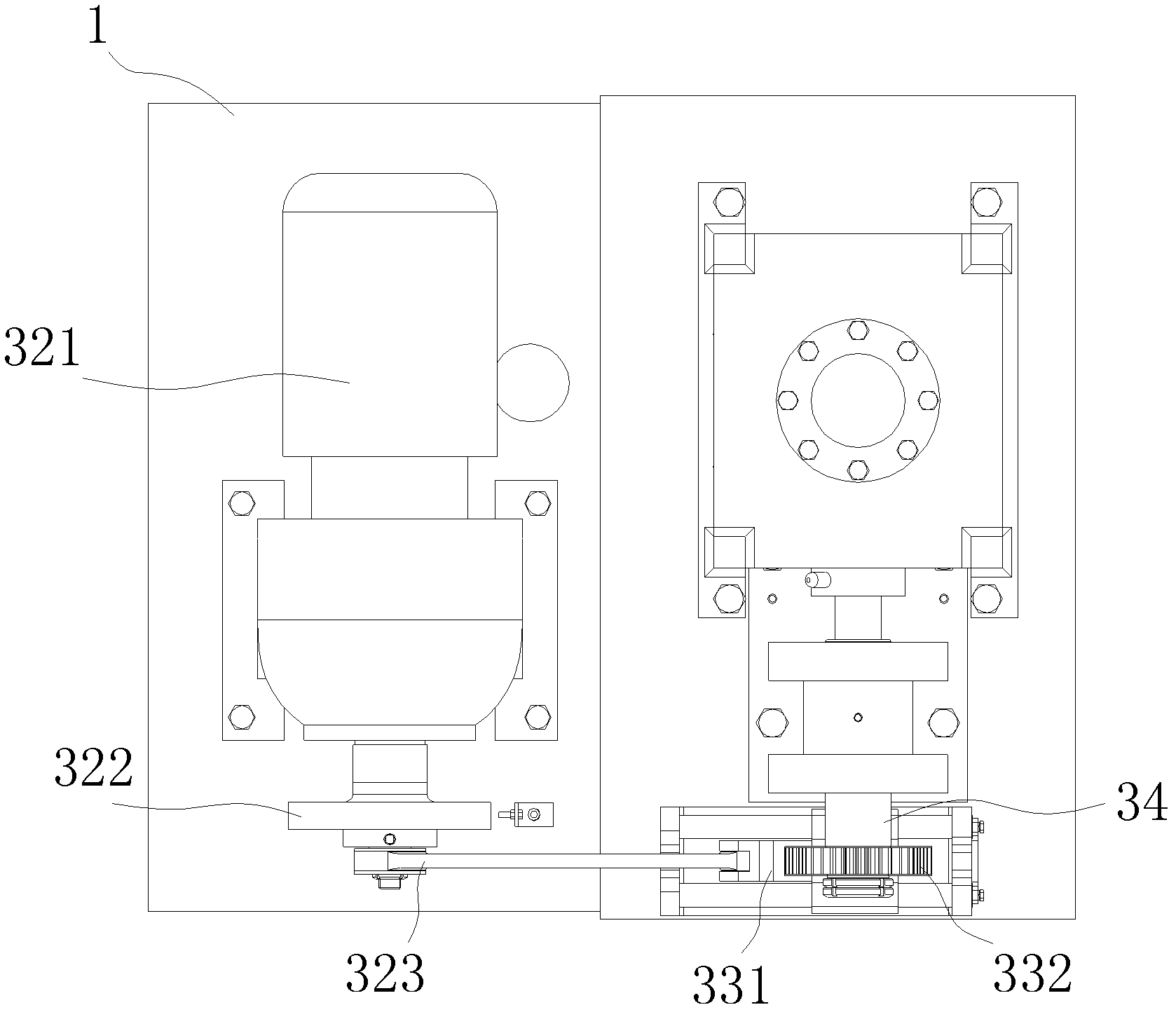

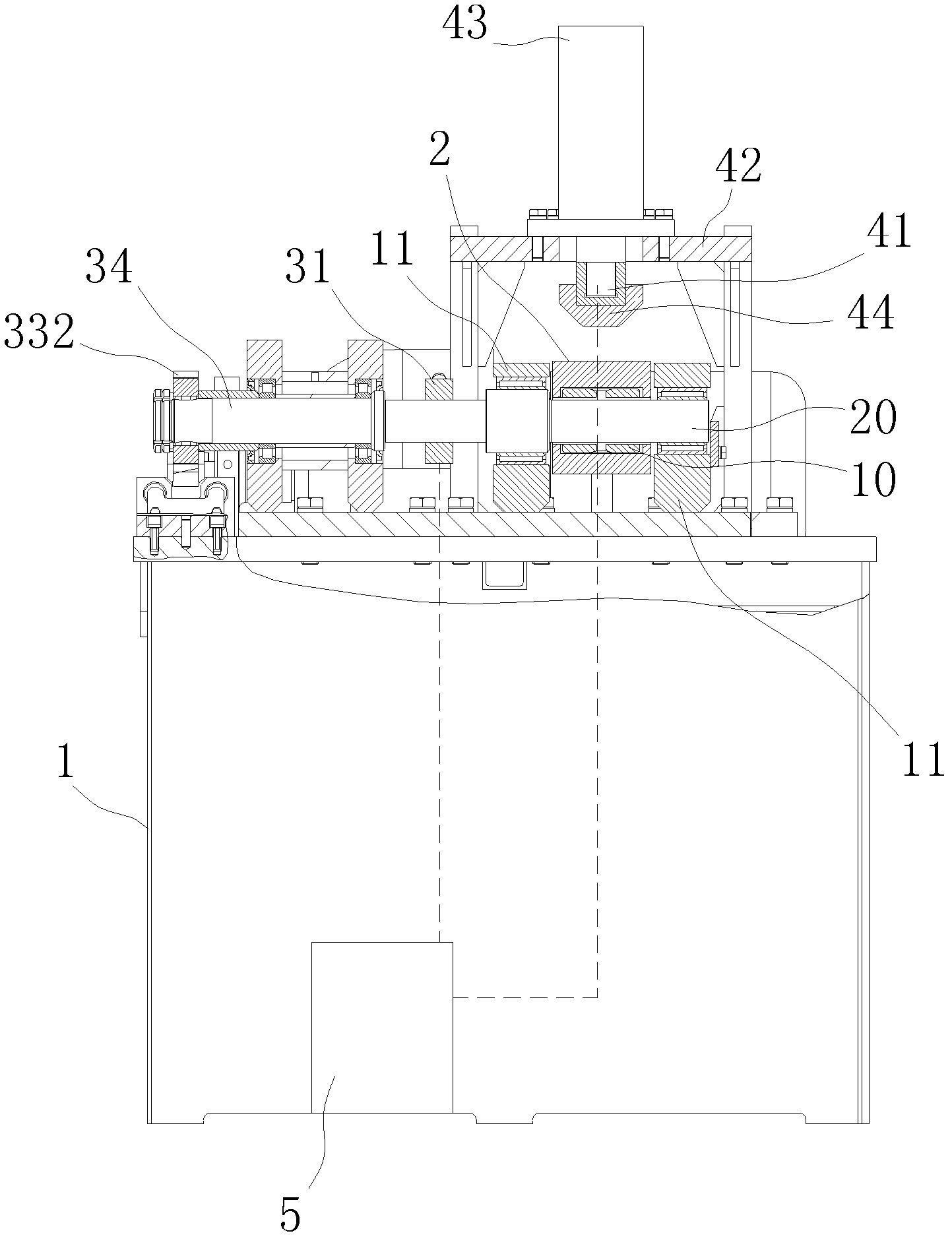

The invention discloses a wobble bearing type friction test device and method. The wobble bearing type friction test device comprises a base frame, a fixing tooling, a driving part, a pressurizing part and a control part, wherein two shaft rod supports are arranged on the base frame; the fixing tooling is used for assembling and fixing a shaft sleeve part and a shaft rod part to be tested; the driving part is used for driving the shaft rod part to do periodic direction-changing rotation in the shaft sleeve part, and the driving part is provided with a torque sensor for detecting the torque acted on the shaft rod part; the pressurizing part is arranged on the base frame and used for exerting pressure on the fixing tooling, and the pressurizing part is provided with a pressure sensor for detecting the pressure exerted on the fixing tooling; and the control part is connected with the pressure sensor and the torque sensor, and used for receiving detection data of the pressure sensor and the torque sensor and performing arrangement and calculation. According to the testing device and method disclosed by the invention, a friction test can be performed on the shaft sleeve and the shaft rod parts so as to guide practices and production.

Description

technical field [0001] The invention relates to a test device and a test method, in particular to a rocking bearing type friction test device and a test method. Background technique [0002] In all kinds of mechanical equipment, there are many structures in which the bushing parts and shaft parts cooperate to complete the movement function. For example, the matching structure of the bushing and the pin shaft on the excavator. Frequent swing bearing reciprocating motion is carried out in the shaft sleeve parts, so friction and wear are easy to occur. In production practice, it is found that with the prolongation of working hours, the wear of the bushing parts and shaft parts will continue to increase, resulting in a larger gap between the two, which will affect the normal use of mechanical equipment and the service life of the bushing and shaft parts. Both will have an impact, and in severe cases, it will cause out-of-stock accidents. [0003] On the other hand, in actual p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/04

Inventor 喻江波官见忠

Owner SANY HEAVY MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com