Laser displacement transducer mounting support provided with adjusting and self-calibrating structure

A technology of laser displacement and mounting brackets, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of lack of benchmarks, trouble, difficulty in checking performance parameters, etc., and achieve high resolution, convenient use, and high control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

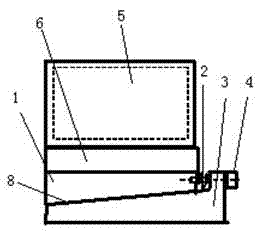

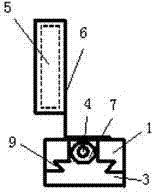

[0019] Such as figure 1 , as shown in 2, the laser displacement sensor mounting bracket with adjustment and self-calibration structure of the present invention includes an upper adjustment bracket 1, a preload spring 2, a lower adjustment bracket 3, an adjustment bolt 4, a sensor base frame 6, and a dial 7 Wait.

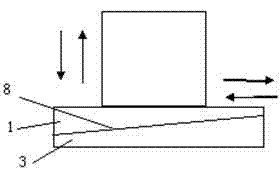

[0020] The lower end surface of the upper adjustment frame 1 and the upper end surface of the lower adjustment frame 3 are connected through a dovetail groove structure 9 with a slope 8. The right end surface of the upper adjustment frame 1 is provided with an adjustment screw hole, and the right side of the lower adjustment frame 3 is convex. Adjusting bolts 4 are connected in the table, and the upper adjusting frame 1 and the lower adjusting frame 3 are adjustable through the adjusting bolts 4 and threaded holes, and the adjusting bolts 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com