Method for removing hexaldehyde and 2-heptanone in cyclohexanone

A technology of cyclohexanone and hexanal, applied in the field of organic chemical purification, can solve the problems of high energy consumption and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

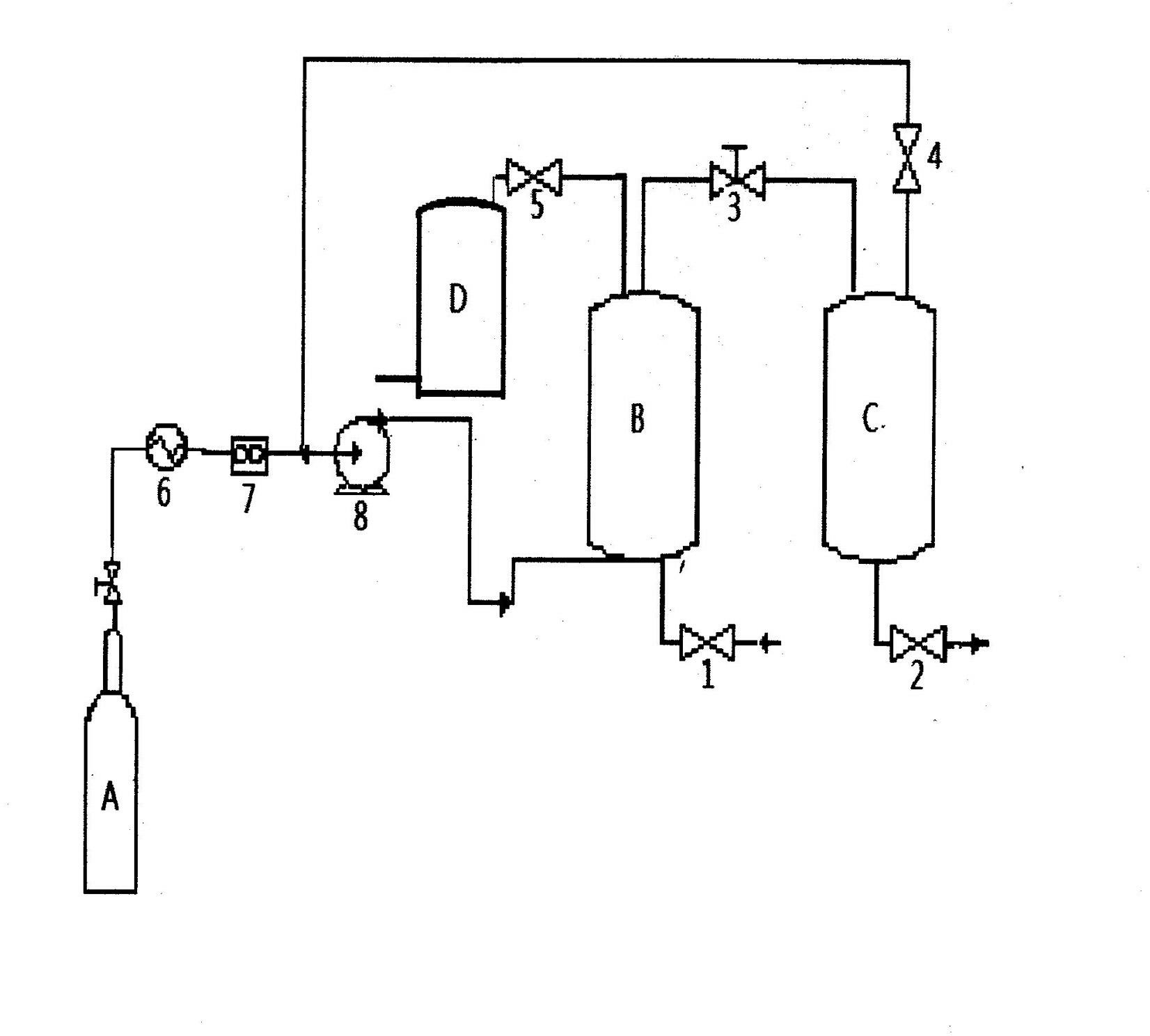

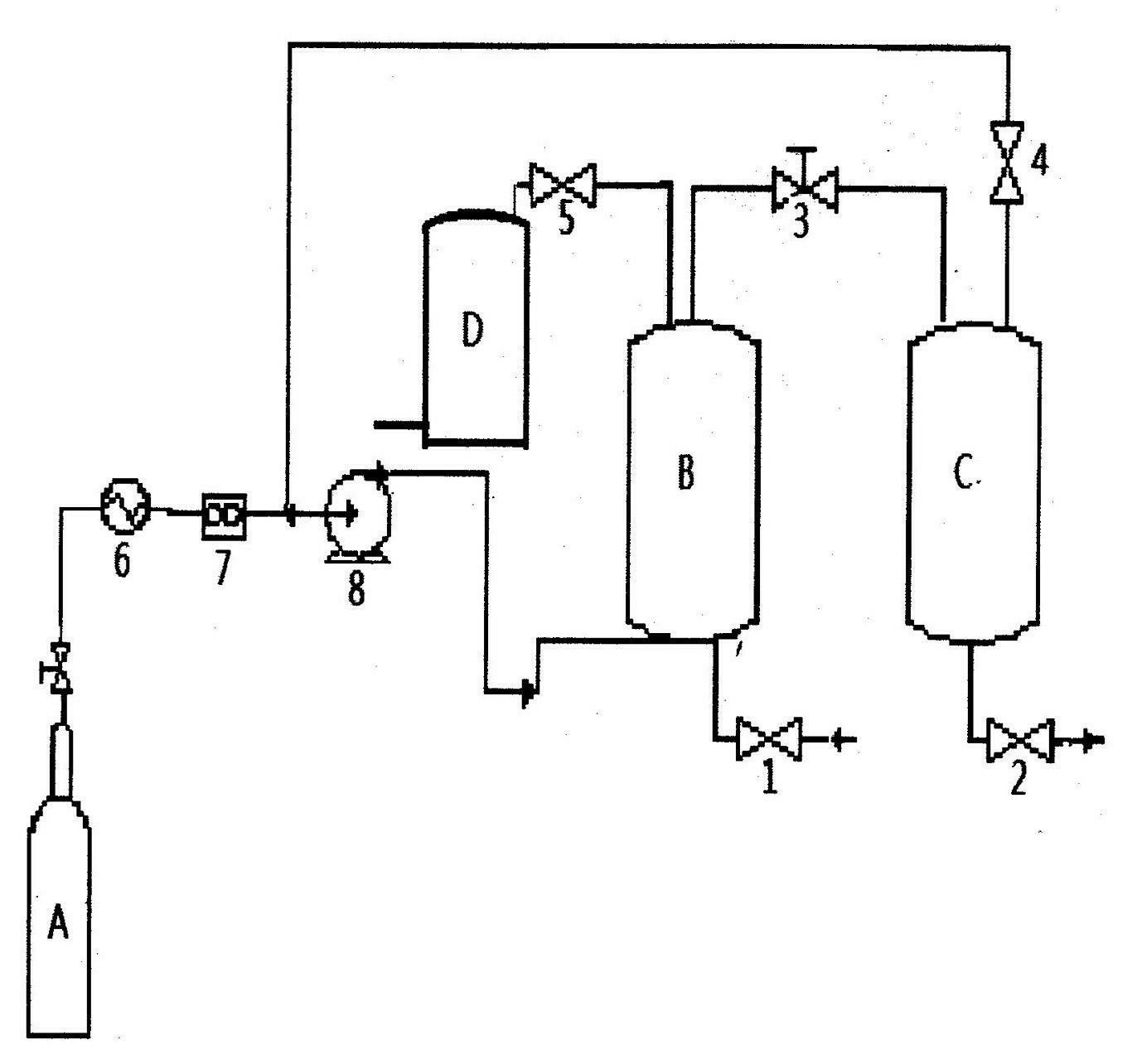

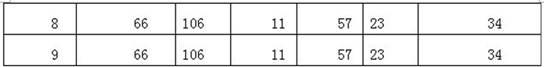

[0025] Use 1226gHZSM-5 type molecular sieve to adsorb cyclohexanone whose hexanal content is 106mg / kg and 2-heptanone is 57mg / kg, and use the flow pump to control the flow rate to be 66ml / min. figure 1 In the shown adsorption column (height 1000mm, inner diameter 50mm, volume 1.96L), the bottom feed, the adsorbed cyclohexanone flows out from the top of the adsorption column, and another stainless steel bucket collects it. Every two hours, samples were taken from the top of the adsorption column and the contents of hexanal and 2-heptanone were analyzed by gas chromatography. It is found that the molecular sieve can ensure that the total content of hexanal and 2-heptanone is less than 40 mg / kg within 10 hours at one volume space velocity, fully meeting the requirements of chemical fiber grade cyclohexanone. Experiments also show that molecular sieves also have a certain adsorption effect on other impurities, such as cyclohexanol and pentanol.

[0026] 1226g strip molecular siev...

Embodiment 2

[0039] static adsorption dynamic desorption

[0040]At 30°C, use HZSM-5 type molecular sieve to adsorb the cyclohexanone solution with hexanal content of 116mg / kg and 2-heptanone of 87mg / kg, and control the molecular sieve mass and cyclohexanone volume ratio to 0.08g / ml When the adsorption time is 12h, the removal rate of hexanal reaches 100%, and the removal rate of 2-heptanone reaches more than 99%; To 10MPa, the temperature is 40°C, the supercritical gas flow rate is 16m3 / h, and the desorption time is 4 hours. Then carry out decompression separation and desorption with supercritical carbon dioxide gas. Due to the super-diffusion of supercritical gas, molecules can diffuse into the deep capillary pores of molecular sieves. -Heptanone dissolves, and in the separator, when the system pressure becomes normal pressure, carbon dioxide returns to the original storage tank from the top in the form of gas, while hexanal and 2-heptanone are in liquid form and can be discharged from...

Embodiment 3

[0042] On-line Desorption Test Using Activated Carbon Adsorption

[0043] At 20°C, use 1300g of granular activated carbon to adsorb cyclohexanone solution with hexanal content of 116mg / kg and 2-heptanone of 77mg / kg, and use a convection pump to control the flow rate to 68ml / min. figure 1 At the bottom of the adsorption column shown (height 1000mm, inner diameter 50mm, volume 1.96L), the adsorbed cyclohexanone flows out from the top of the adsorption column, and an empty stainless steel barrel collects it. Every two hours, samples were taken from the top of the adsorption column and analyzed for hexanal and 2-heptanone. Using gas chromatography analysis, it is found that activated carbon can ensure that the total content of hexanal and 2-heptanone in the outlet is less than 40mg / kg within 10h under one volume space velocity, and the concentration of hexanal and 2-heptanone in the outlet exceeds 40mg / kg. kg, the desorption can begin if the product quality requirements cannot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com