Pressure measuring unit of compressor

A technology of pressure measuring device and compressor, which is applied in the direction of pump testing, mechanical equipment, machine/engine, etc. It can solve the problems of time-consuming, manpower-consuming, error and other problems of testing procedures, so as to save labor costs, and the process of installing compressors is fast, Effects of Avoiding Errors in Judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

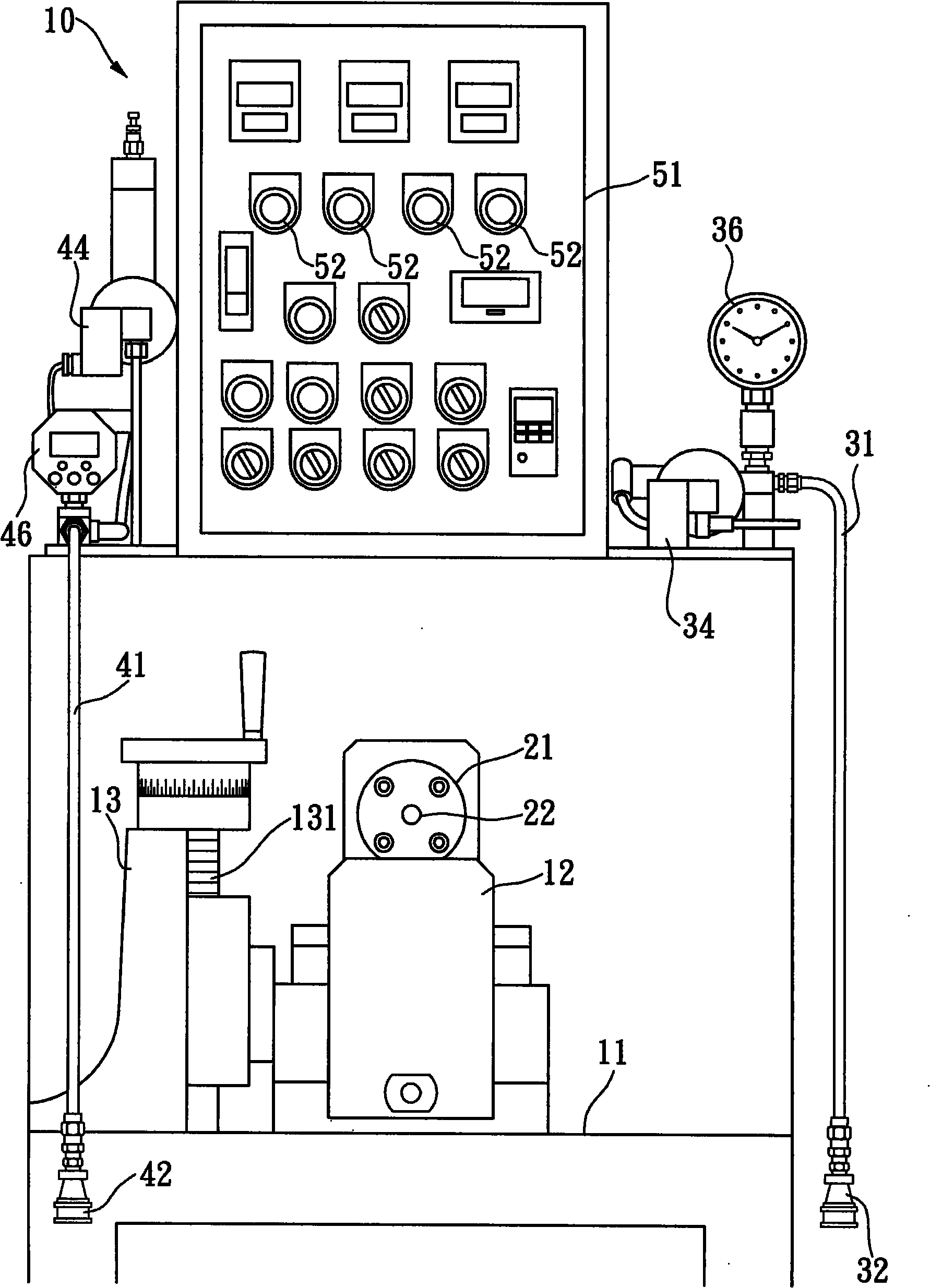

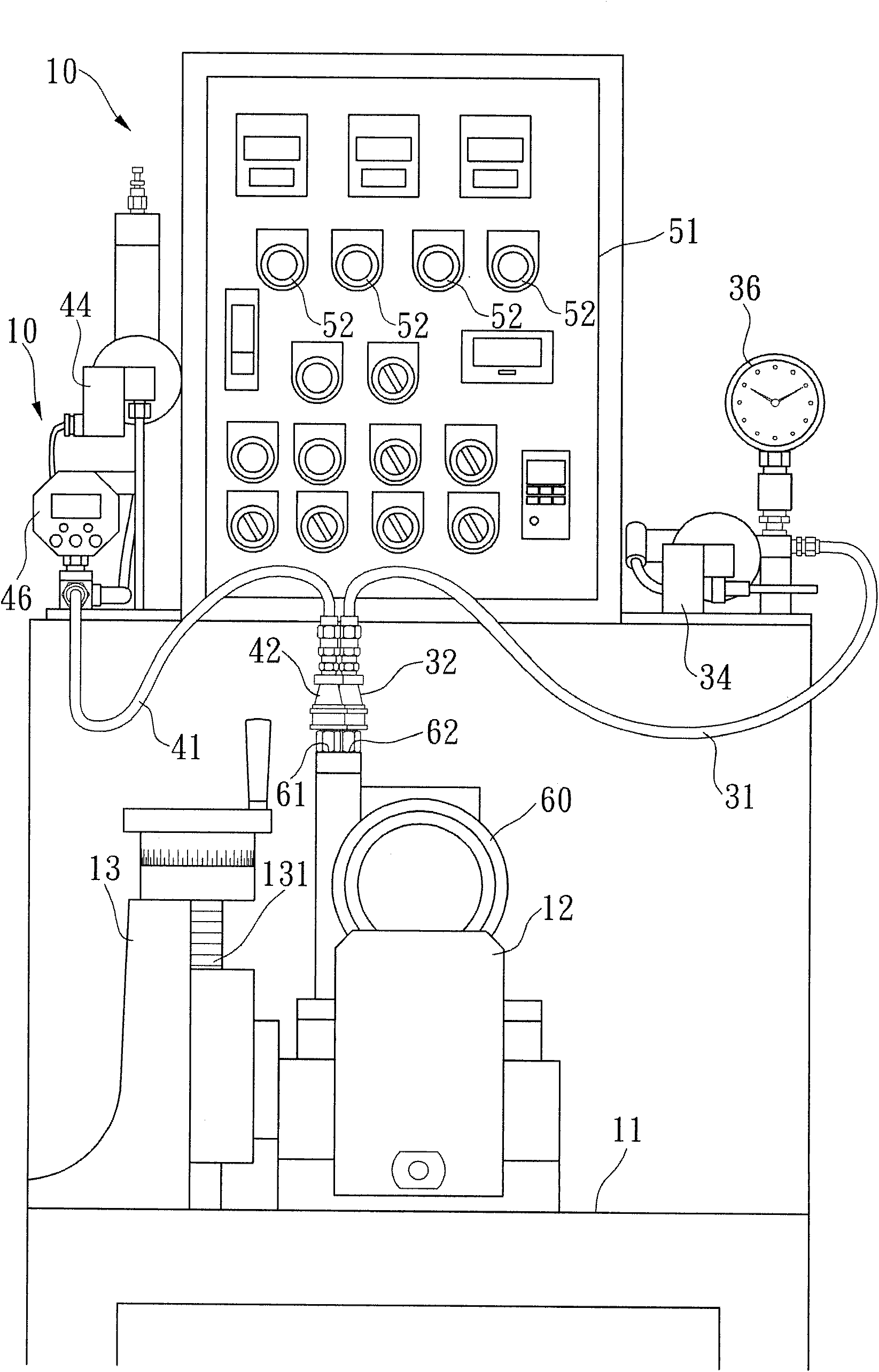

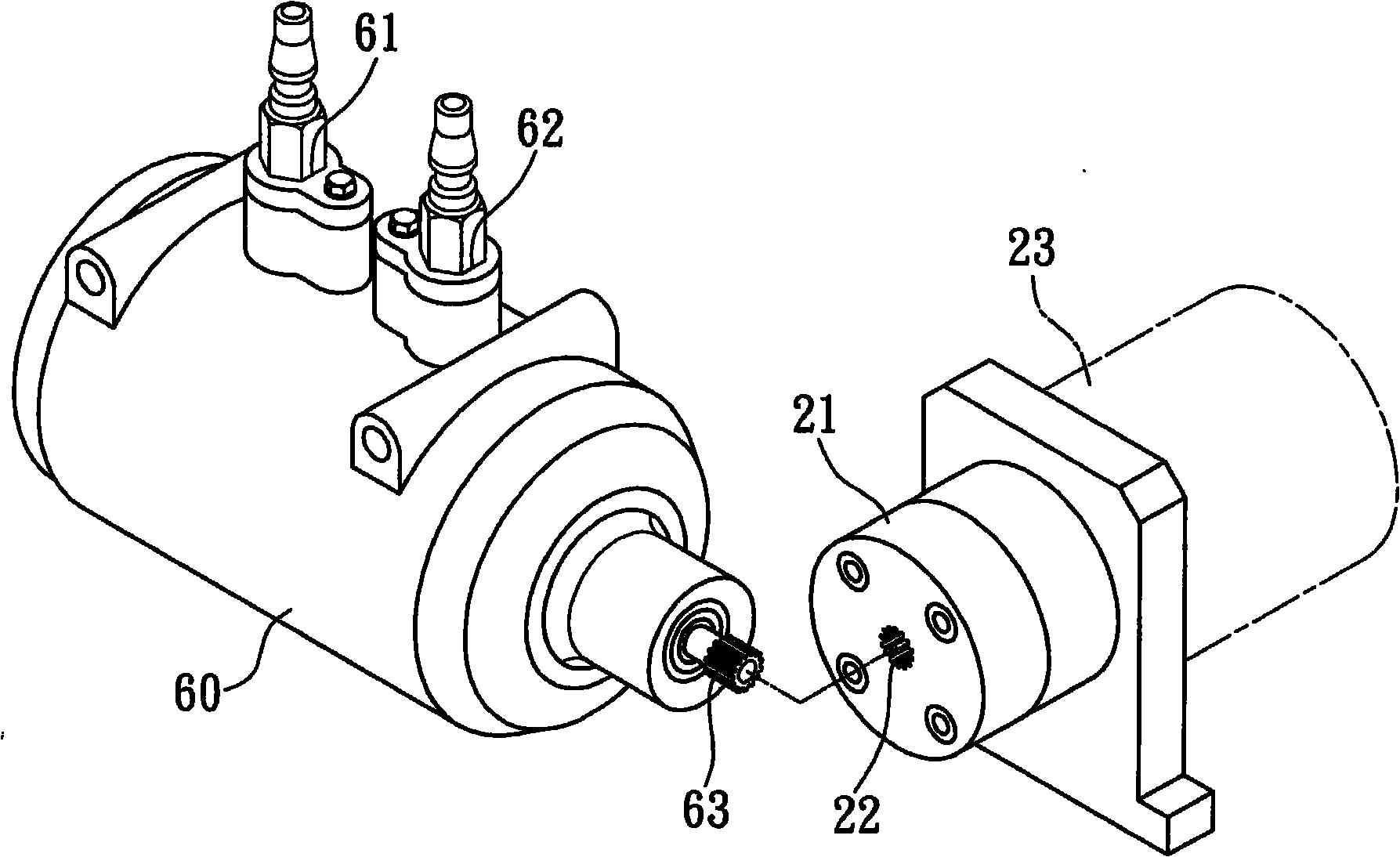

[0019] see Figure 1 to Figure 3 , the present invention provides a compressor pressure measuring device 10, which is used to connect with the inlet port 61 and the outlet port 62 of a compressor 60, and can drive the transmission shaft 63 of the compressor 60 to run, so as to perform pressure measurement work , the compressor pressure measuring device 10 is mainly composed of a carrier 11, a jig 21, a positive pressure pipeline 31, a negative pressure pipeline 41 and a control module 51, wherein:

[0020] The platform 11 has a clamp 12 for clamping the compressor 60, and a lifting mechanism 13 is provided on the clamp 12. In this embodiment, the lifting mechanism 13 has a One side of the clamp 12 is slid on the slide rail 131 of the elevating mechanism 13 , and the lifting adjustment action can be performed along the slide rail 131 .

[0021] The jig 21 has an inner toothed hole 22 through which the drive shaft 63 of the compressor 60 can pass through, and the jig 21 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com