Variable displacement scroll compressor

A scroll compressor, variable displacement technology, applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., can solve the problems of refrigerant leakage, reduction of compressor compression efficiency, inappropriate compression, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

[0115] Then refer to Figures 13A to 13D A second embodiment of the present invention is described. said Figures 13A to 13D is an explanatory diagram for describing the operation of the compressor 10 of the present embodiment. said Figures 13A to 13D Corresponding to the first embodiment respectively Figures 9A to 9D .

[0116] In the first embodiment, the main bypass port 22h is located at a position where the first imaginary line L1 and the third imaginary line L3 coincide, and the secondary bypass port 22h and the main bypass port 22g are formed as independent holes. On the contrary, unlike the first embodiment, according to the present embodiment, the sub bypass port 22h and the main bypass port 22g are formed as a common single hole. In this embodiment, descriptions of components similar to those in the first embodiment will be omitted or simplified.

[0117] In this example, as in Figures 13A to 13D As shown in , an annular hole is formed at a position shifte...

no. 3 example

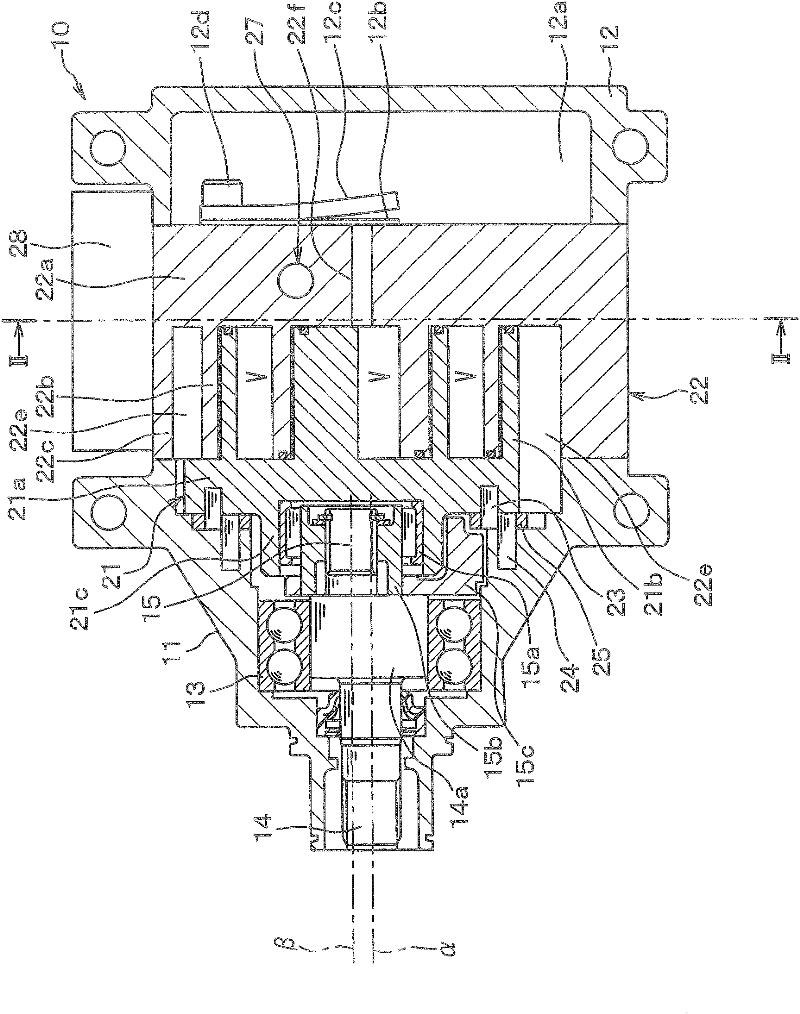

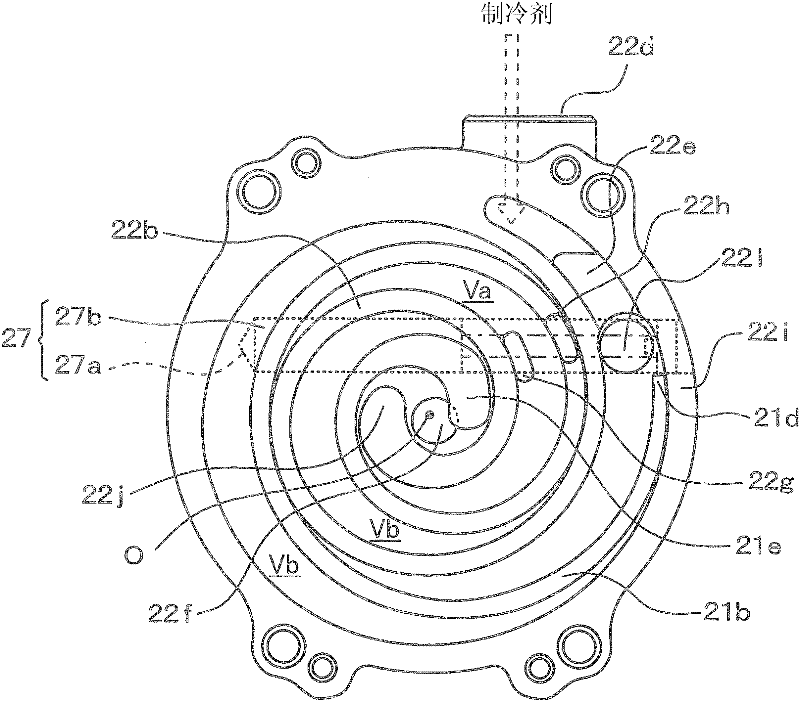

[0122] Refer below Figures 14 to 15 A third embodiment of the present invention is described. Figure 14 is a longitudinal sectional view of the compressor 10 of this embodiment, Figure 15 yes Figure 14 The sectional view seen along the line XV-XV in the middle.

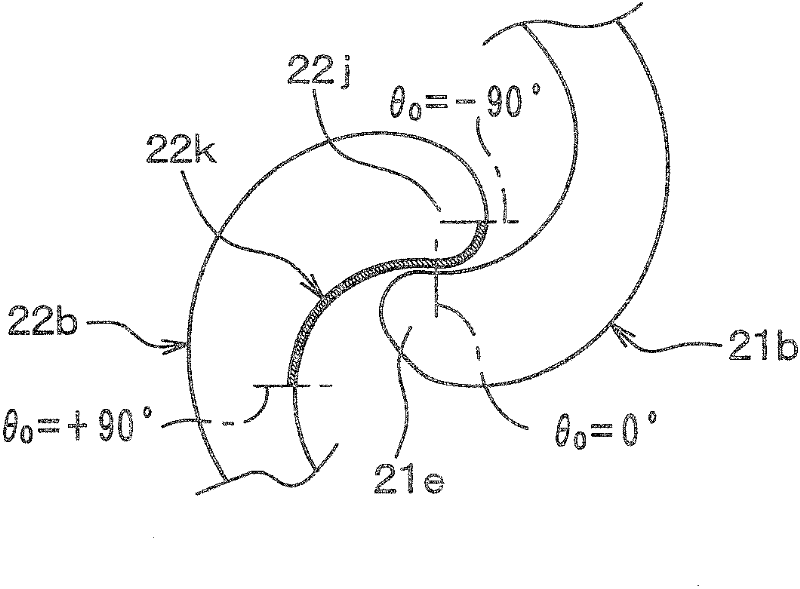

[0123] The compressor 10 of this embodiment differs from the compressor 10 of either of the first or second embodiments in the following points. That is, unlike in the first and second embodiments, in this embodiment, the volume of the radially outer compression chamber V located on the radially outer side of the scrolls 21, 22 is larger than the volume of the radially outer compression chamber V located on the scrolls 21, 22. The volume of the radially inner compression chamber V on the radially inner side. In this embodiment, descriptions of components similar to those in the first embodiment will be omitted or simplified.

[0124] Such as Figure 14 and 15 As shown, in this embodiment, a step 22m is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com